ZKRFM Standing seam Roll Forming Machine

Product descriptions from the supplier Overview

PRODUCT DESCRIPTION OF Zhongke Standing seam Roll Forming Machine

Introducing the innovative vertical seam welding machine from Zhongke Roll Forming Machinery Factory, a pinnacle in precision engineering for the metalworking industry.

Low vertical edge machines, especially in the field of metal roofing and sheet processing, have several significant advantages. Here are ten main advantages of low edge machines:

Excellent waterproof performance: The plate produced by the low vertical edge machine is connected by the bite fixing method, and the roof has no screw penetration, effectively preventing the problem of water leakage due to the thermal expansion and contraction of the screw hole, especially suitable for roofing systems requiring high waterproof performance such as villas.

High aesthetics: Because there is no need to fix screws, the roof is cleaner and more beautiful, which meets the aesthetic requirements of modern architectural design.

High production efficiency: low vertical edge machines are usually equipped with PLC computer control system to achieve automated production, which greatly improves production efficiency and reduces labor costs.

High processing precision: The use of advanced cold forming technology, can accurately control the shape and size of the plate, to ensure product quality.

Strong adaptability: The low vertical edge machine can process a variety of shapes of plates, such as rectangular plates, fan plates, etc., to meet the needs of different architectural designs.

Material saving: The low vertical edge design makes the aluminum plate lose less, the system load is small, the structural stability is high, and the material cost is reduced.

Good structural stability: the low vertical edge system adopts a combination of fixed fasteners and sliding fasteners, which can absorb the displacement caused by thermal expansion and cold contraction, prevent plate deformation or cracking, and improve the stability of the structure.

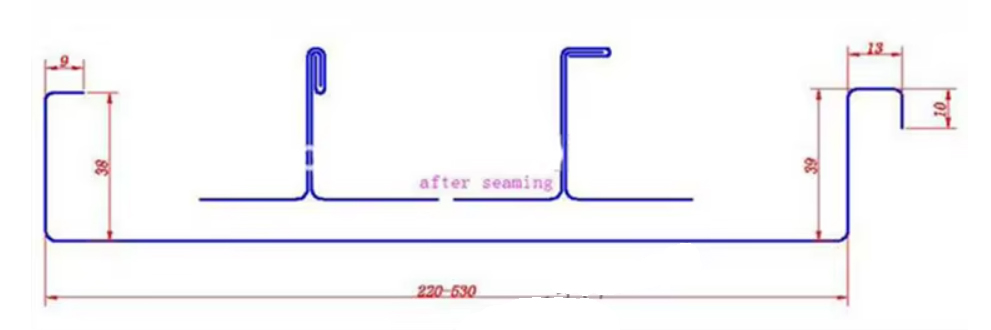

Roof Tile OF Zhongke Standing seam Roll Forming Machine

| ITEM | SPECIFICATION | |

|

Material |

Raw material | PPGI/GI/PPGL/GL |

| Material thickness | 0.7-1.2mm | |

| Feeding width/coil width | 270-600mm | |

|

Machine |

Roller stations | 8 stations |

| Shaft diameter | 40mm | |

| Shafte material | 45# steel with Hard chrome plating | |

| Roller material | 45# steel with hard chrome coating | |

| dimension | 2400*1400*1600mm | |

| weight | 1500kg | |

| color | customize | |

| Forming speed | 0-18m/min | |

| Main frame | 350H Steel Welding | |

|

Cutter |

Cutter material | Cr12 with hard treatment |

| Cutting method | Hydraulic cutting | |

| Hydraulic station motor power | 2.2kw | |

| Transmission motor | 4kw | |

| voltage | 380V,50Hz,3phrase(as the customer’s requests) | |

| PLC brand | Delta PLC | |

|

Control system |

Language | English ,Chinese,Spanish |

| Operation | Manual |

MACHINE DETAILS OF Zhongke Top Hat Section Channel Machine

|

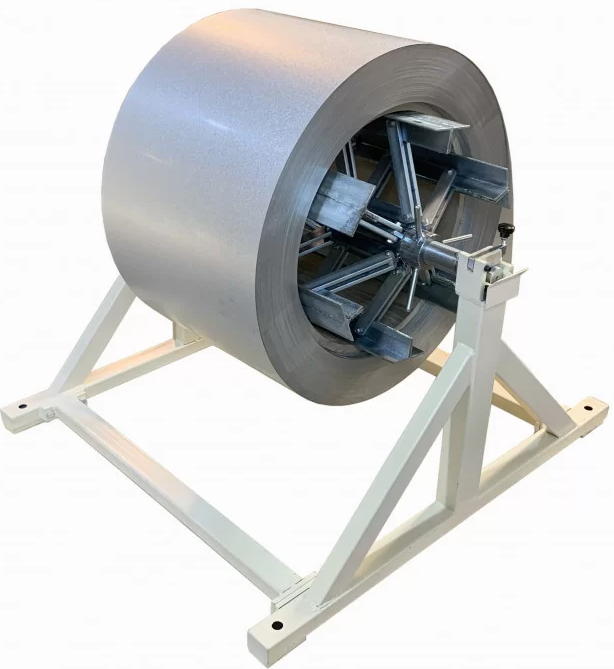

5 tons manual Coiler |

1.Usage:It is used to support the steel coil and uncoil it in a turnable way.2.Inner diameter: 450-508mm

3.The maximum weight it can bear is 5 tons

|

|

|

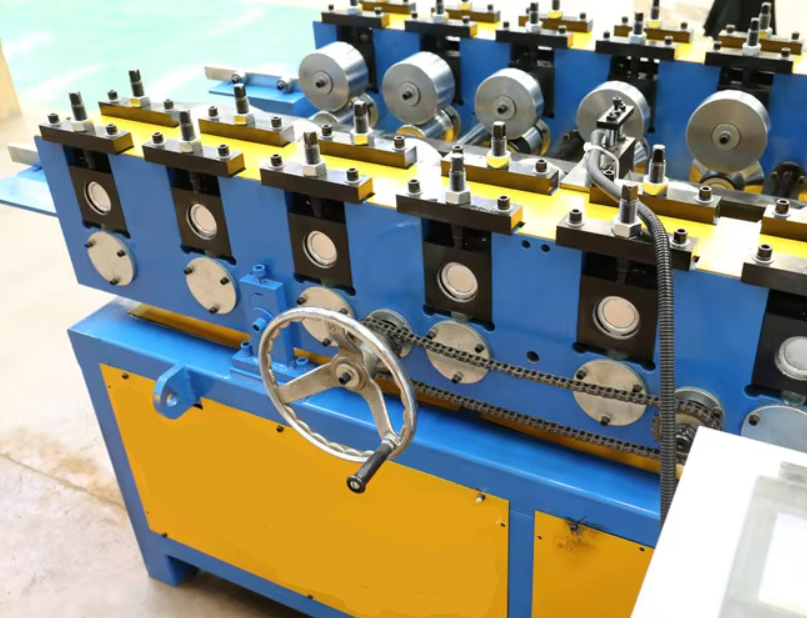

Forming system |

Rollers: design by senior engineers with Auto-cad software, manufactured with 45# high grade steel Shaft: 100mm manufactured

Supporting frame: 350H steel to guide the forming station bearing basement The finished products will change if using different material and thickness |

|

|

Hydraulic cut-off |

|

|

COMPANY INTRODUCTION OF Zhongke TR4 Single Layer Roll Forming Machine

Zhongke Roll Molding Machine Factory, as the industry's leading intelligent manufacturing pioneer, focuses on the development and production of high-quality roll molding equipment. We combine cutting-edge technology and ingenuity to create roller forming machines with excellent performance, easy operation, high efficiency and energy saving, which are widely used in automotive, aviation, building materials and other fields. With customer needs as the core, we provide customized solutions to help enterprises improve production efficiency, reduce costs, and lead industrial upgrading. Choose Zhongke, join hands to create a new future of intelligent manufacturing!

OUR CUSTOMERS OF Roof Sheet Roll Forming Machine

Our products are sold to many countries and regions all over theworld, and we have established long-term cooperative relations with clients!

PACKAGING & LOGISTICS OF Door Frame Roll Forming Machine

FAQ

1.Q:Are you manufacturer?

A:Yes,we are manufacturer for cold roll forming machine over 17 years.

2.Q: if you can accept OEM? Design and manufacture according our photo.

A: Yes, we can accept OEM,we owned expert engineer team, and use famous brand components according your demands.

3.Q:What's the warrany for our machine?

A: we provide 2years guarantee and provide lifetime technical support.

4.Q:How many workers is needed for the machine operation ?

A: One worker is engough, the machine use automatic PLC control system.

5.Q.Can you be responsible for transport?

A.Yes,we owned expert export team, we can arrangement for you to your destination port or address.

6.Q:What service can you provide before order?

A:About the pre-sale service, We provide professional solutions according your demands, such as design, technical parameter,

delivery flow etc. at the same time, we can supply invitation letter for your visit our factory and know more our factory.

7.Q: What is the after- sale service?

A: we will supply lifetime technical support and supply quick-wear parts within 2years.

8. Q: What's the delivery time?

25 days after deposit receipt your payment

9.Q: Installation and training

a.If buyers visit our factory and check the Glazed tile making machine color steel tile forming machine , we will teach you how to install and use the machine, and also train your workers/technician face to face.

b.Without visiting, we will send you user manual and video to teach you to install and operate.

c.If buyer needs our technician to go to your local factory, we could go abroad to guide you for free, but you should pay the Transportation and accommodation expenses.

8. Q:what can you buy from us?

Roof & Wall Roll Forming Machine,Floor Deck Roll Forming Machine,Light Steel Keel Roll Forming Machine,CZ Purling Roll Forming Machine,Leveling Slitting Roll Forming Machine and other related machine.