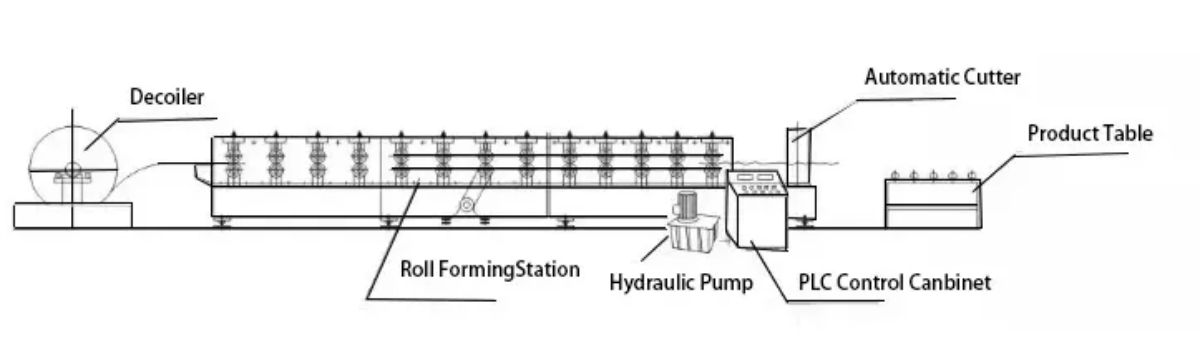

ZKRFM Stand Seam Forming Machine

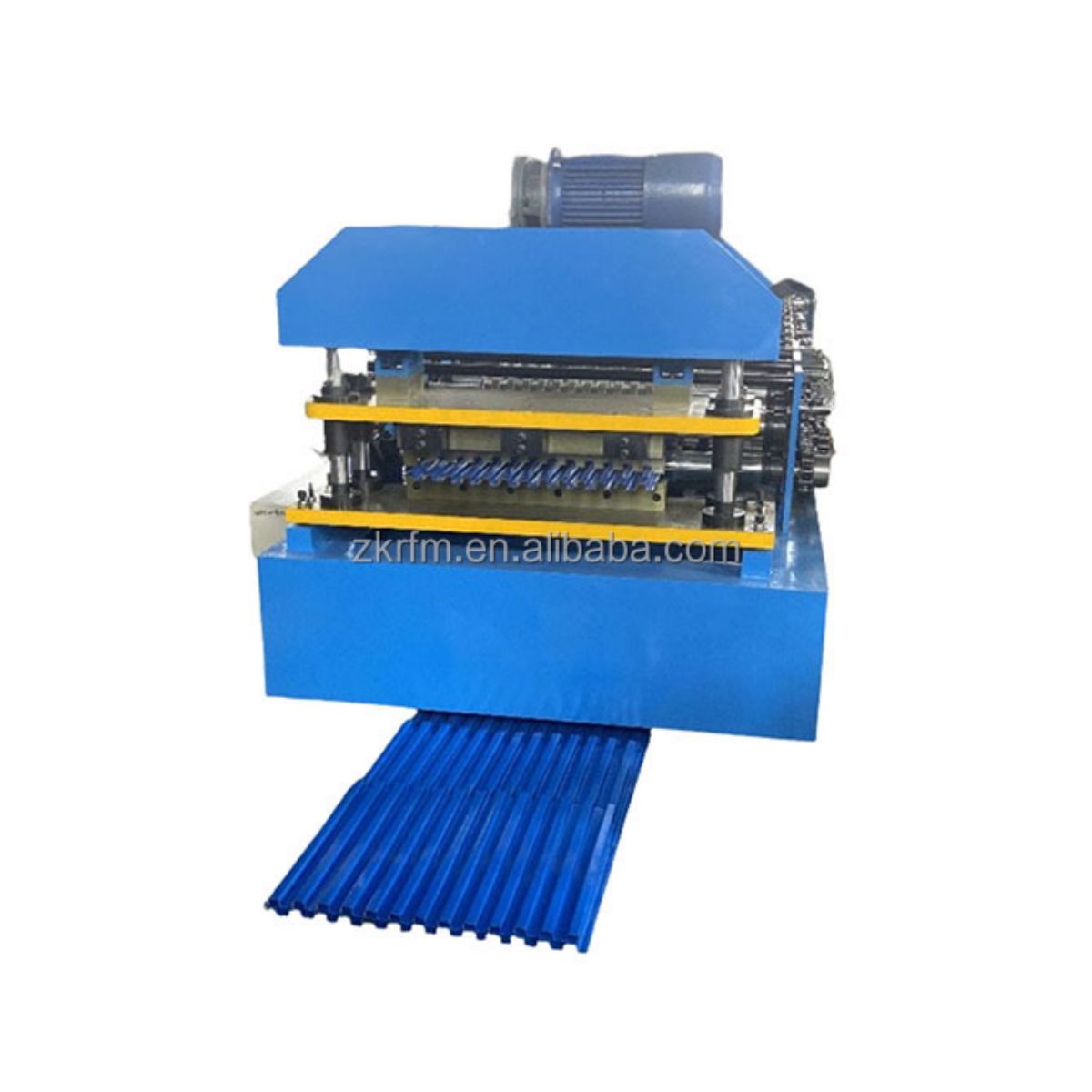

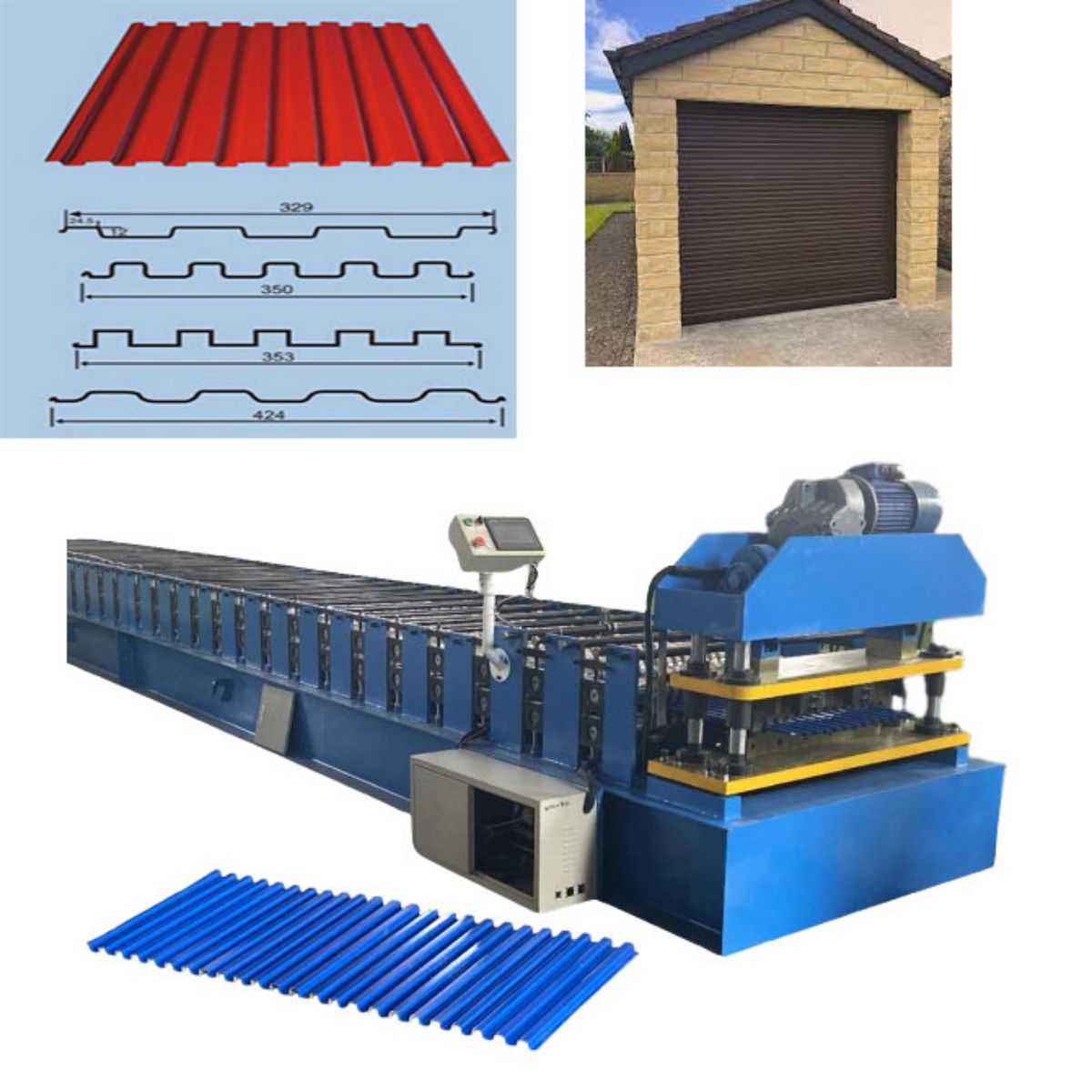

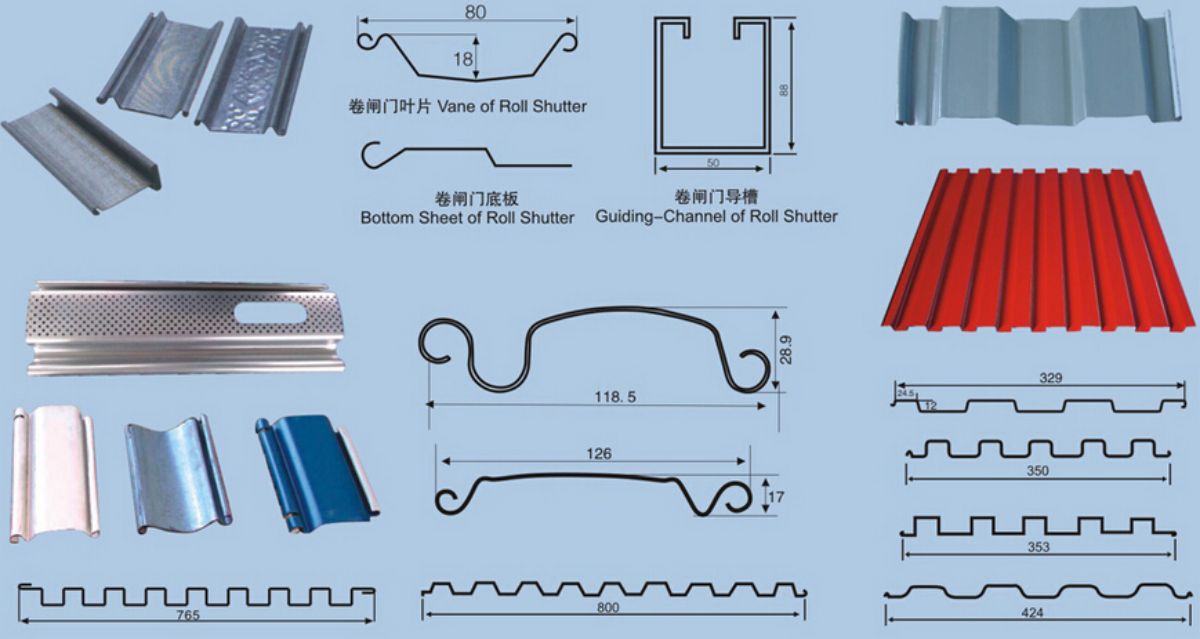

The roller shutter door machine is made by cold-formed forming process. It is widely used by people for its energy-saving and environmentally friendly features. It uses less steel to complete the required specified load, and no longer depends on increasing the amount of plates or materials. The mechanical properties of the steel can meet the load requirements, but the mechanical properties of the steel can be improved by changing the cross-sectional shape of the steel product. Cold bending is a material-saving and energy-saving new metal forming process and new technology. Cold bending is a multi-pass forming and rolling that is arranged in sequence to continuously bend the coils and other metal plates and strips in the transverse direction. Make profiles of specific

cross-sections

| No | Item | Data |

| 1 | Raw material width | 800-1200 mm |

| 2 | Sheet effective width | 600-1000 mm |

| 3 | Raw material | Color steel sheet , Stainless steel or galvanized steel sheet |

| 4 | Material thickness | 0.3-0.8 mm or customized |

| 5 | Forming roller material | 45# steel plated with chrome |

| 6 | Shaft diameter | 40 mm |

| 7 | Forming roll station | 8-16 steps |

| 8 | Main motor power | 3 KW 4 KW 5.5 KW(according to type) |

| 9 | Hydraulic power | 4 KW (according to type) |

| 10 | Control system | PLC control |

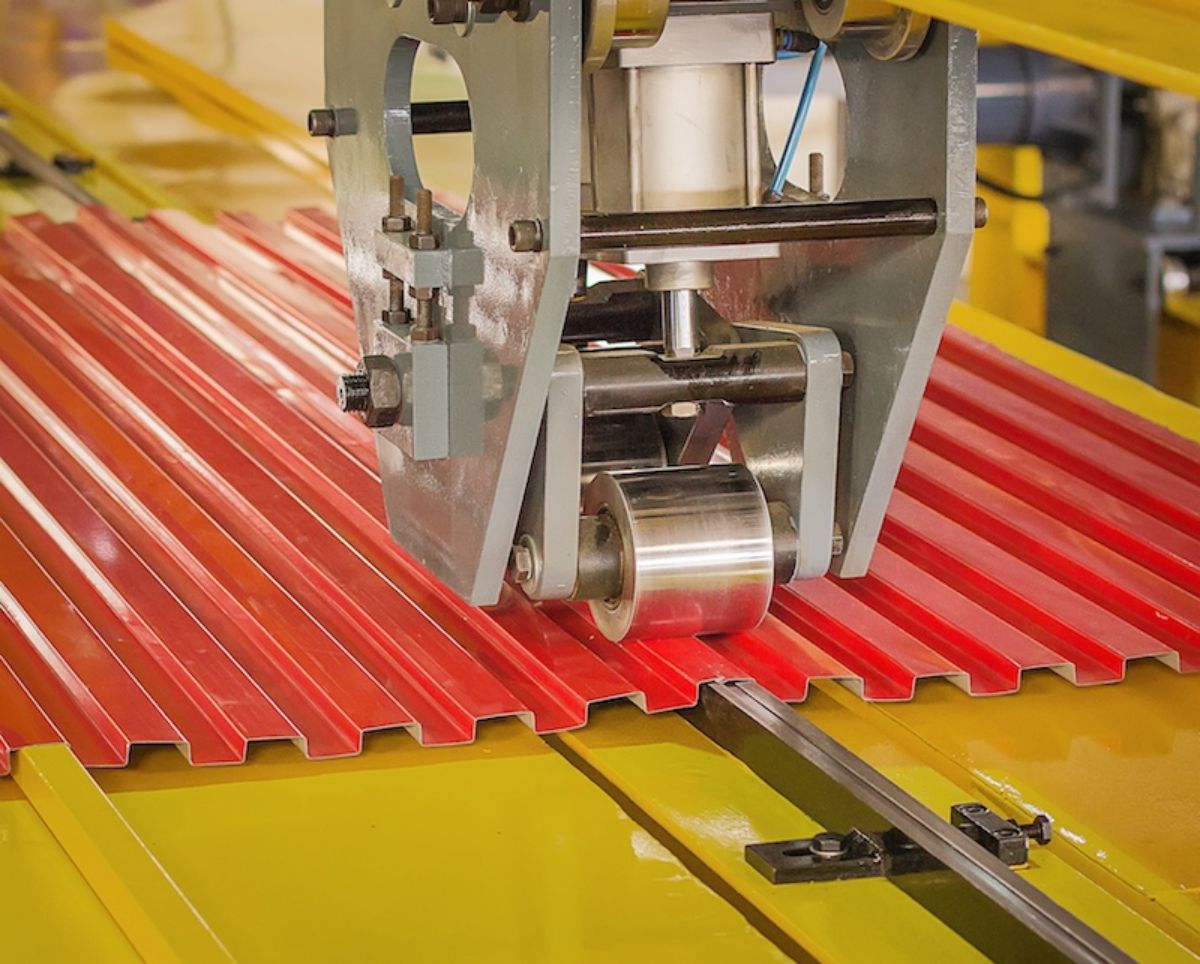

Forming roller

Rolling Shutter Door Making Machine forming roll quality will decide roof sheet shapes, we can according to your local roof shape customized different type rollers

Roller chrome coated thickness: 0.05 mm

Roller material: Forging Steel 45# heat treatment.

Control part

Rolling Shutter Door Making Machine control parts have different types, standard type are button control, through press buttons to realize different function.

PLC touch screen type can setting data on the screen, its price is little higher, but is more intelligent and automatic.