ZKRFM Metal Stud And Track Top Hat Purlin Forming Machine

Product descriptions from the supplier Overview

PRODUCT DESCRIPTION OF Zhongke Top Hat Section Channel Machine

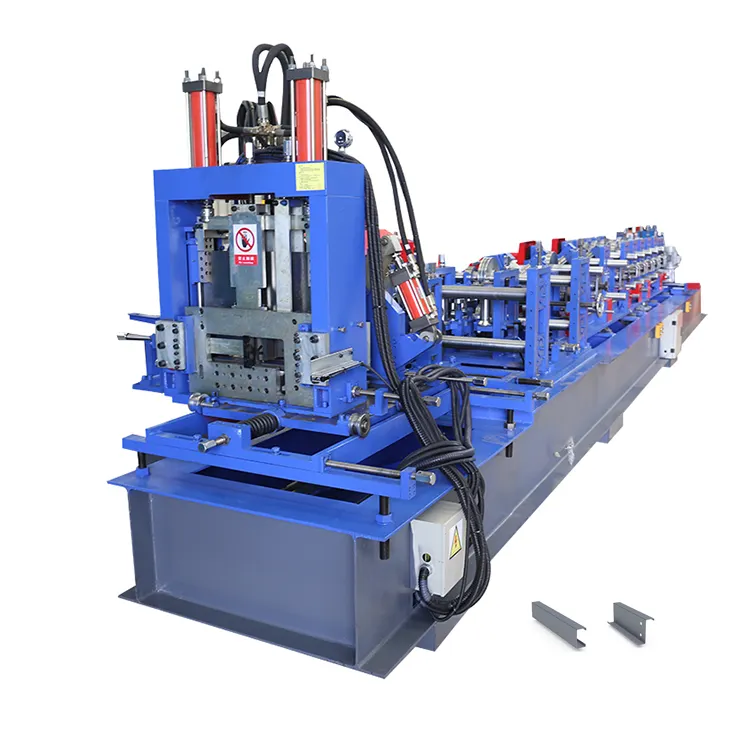

The Zhongke Top Hat Section Channel Machine is a highly efficient and versatile roll forming machine designed to produce precise top hat channels with exceptional accuracy and speed. This machine excels in transforming flat metal sheets into customized top hat sections, catering to diverse industrial needs such as construction, automotive, and furniture manufacturing. Equipped with advanced roller technology, it ensures smooth and continuous forming, minimizing material waste and maximizing productivity. The machine's user-friendly controls allow for easy adjustment of section dimensions and profiles, ensuring flexibility in meeting specific project requirements. Its robust construction and precision engineering guarantee consistent output quality, making it an invaluable addition to any metal fabrication workshop.

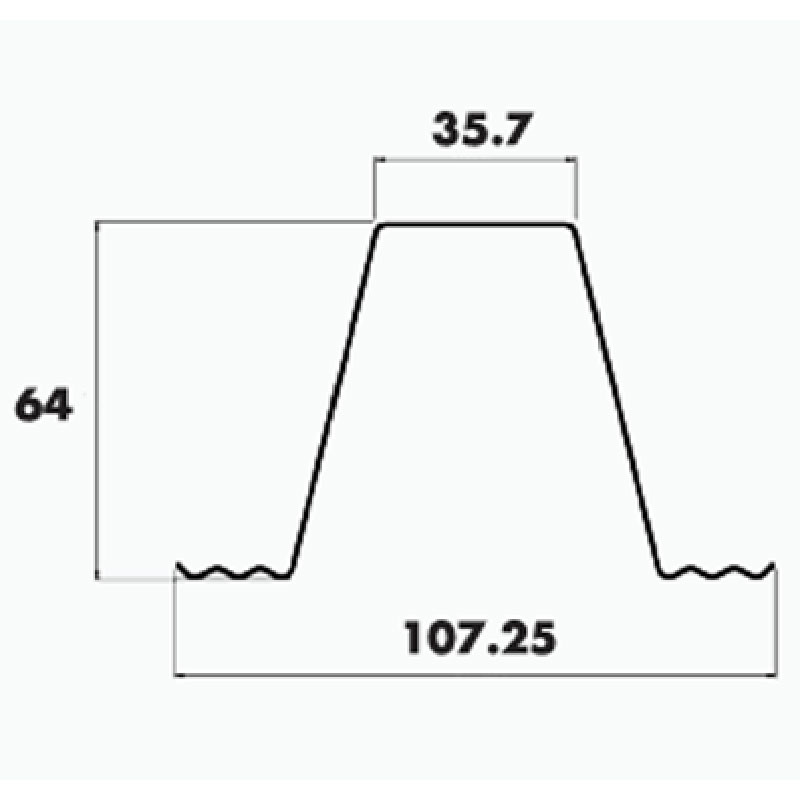

PURLIN SPECIFICATIONS OF Zhongke Top Hat Section Channel Machine

MACHINE DETAILS OF Zhongke Top Hat Section Channel Machine

|

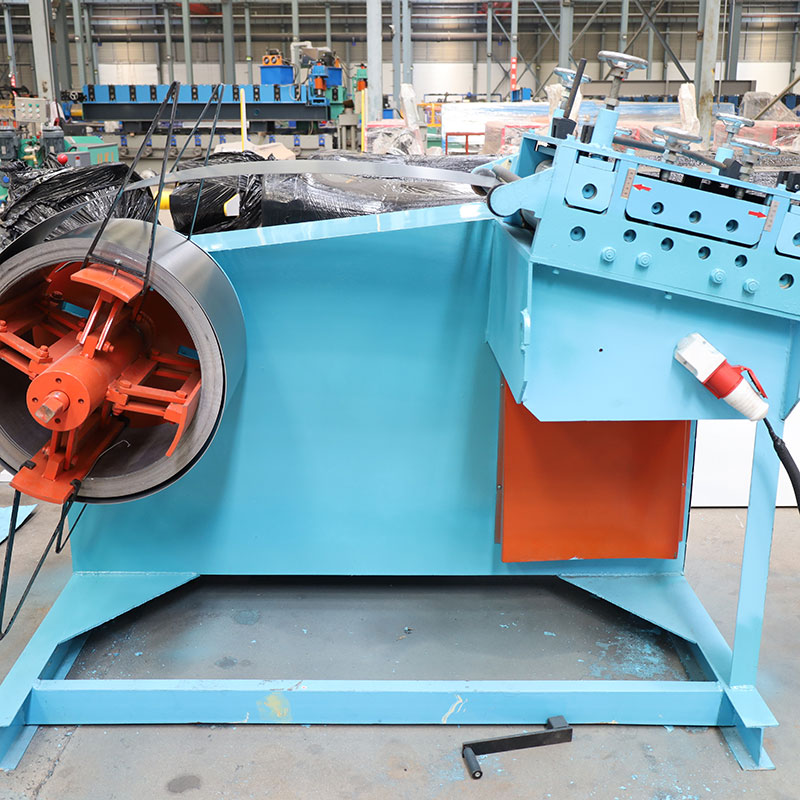

Decoiler

The Zhongke Top Hat Section Channel Machine Decoiler efficiently handles steel coils, bearing & rotating them. It features a micro brake to prevent sudden stops, ensuring safety during inertia forward operation. Accepts coils with inner diameters 430-590mm and outer up to 1300mm. |

|

350 H Frame

The 350 H Frame is an integral part of our roll forming machine, providing robust support and stability. It ensures precise alignment and consistent product quality during the production process. |

|

Travel switch

The Travel Switch is an essential component of our roll forming machine, ensuring precise and automated positioning of materials. It enhances efficiency and accuracy in the production process, making it a valuable tool for our customers. |

|

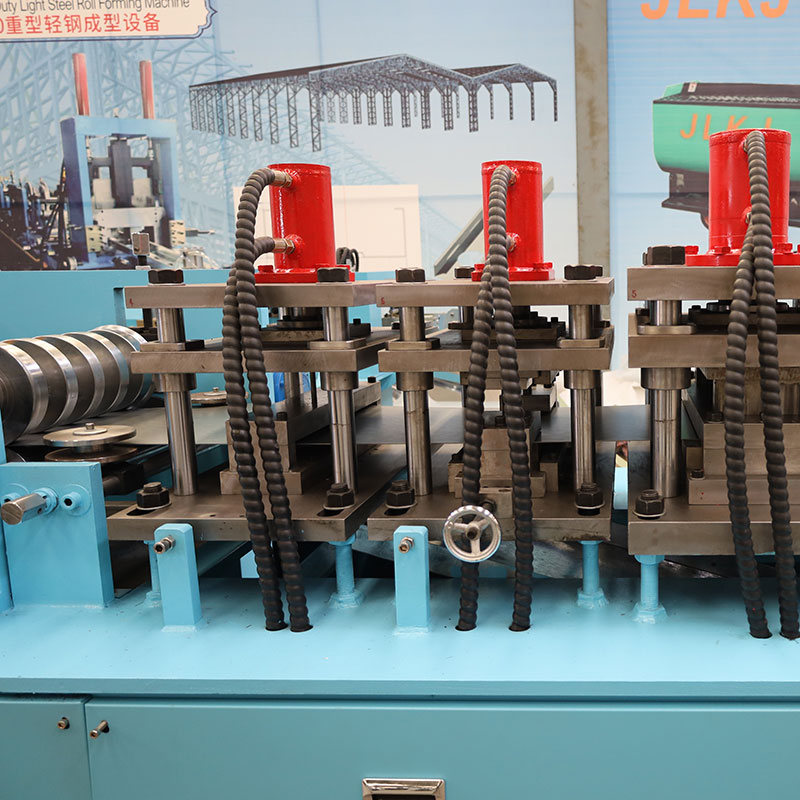

Punching Device

The punching device on the roll forming machine efficiently punches holes or shapes into the material during the forming process. |

|

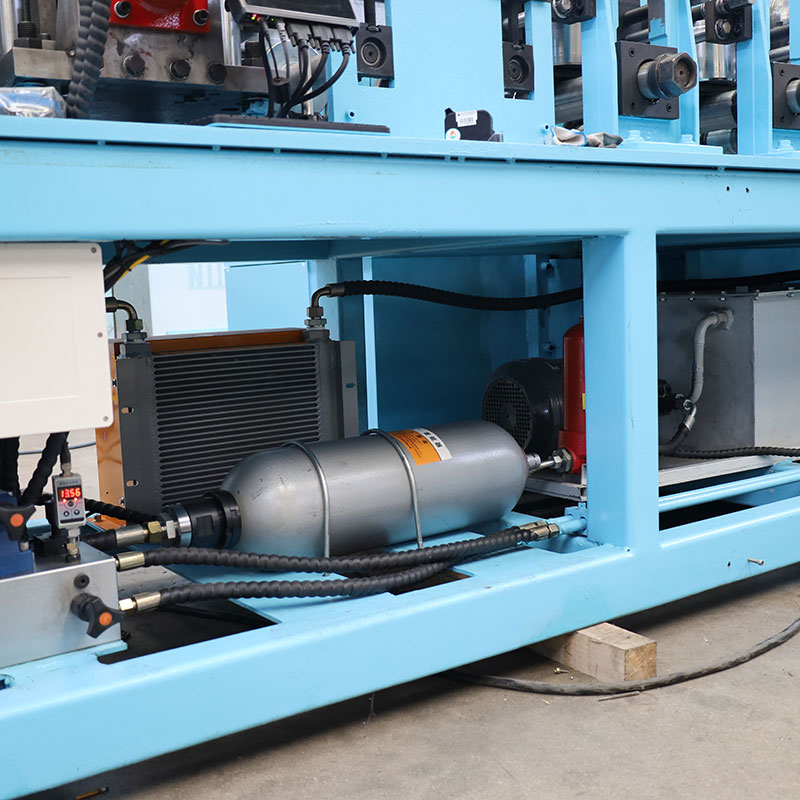

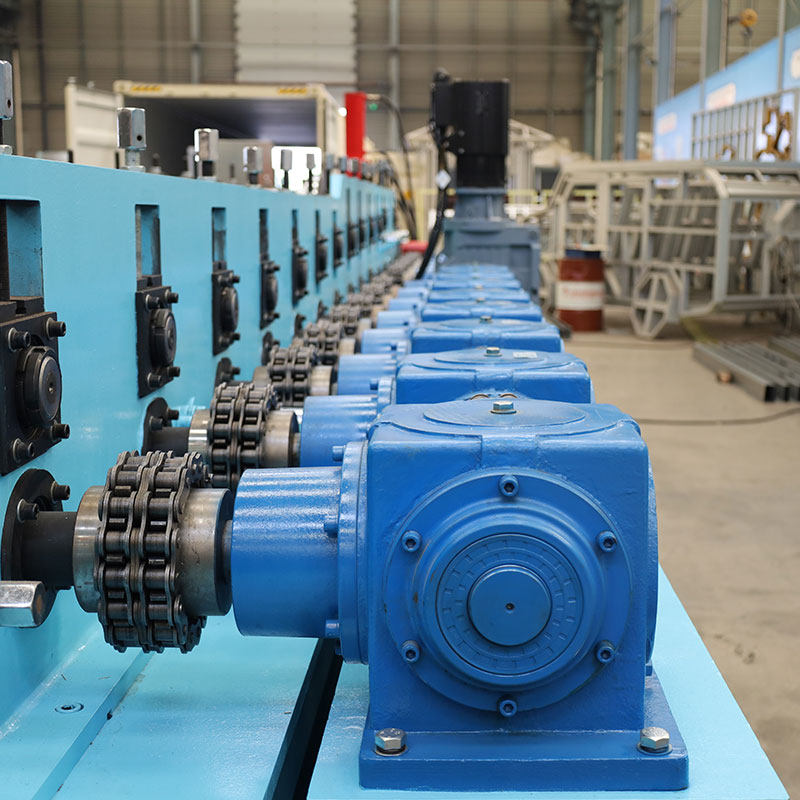

Gearbox Transfer

The gearbox on our roll forming machine functions as a critical component, efficiently transmitting power and reducing speed to drive the rollers, ensuring precise and smooth metal shaping. |

|

High hardness roller

Imported material, DC53. CNC center machining, HRC58-62°, fine grinding |

|

The printer

The printer on the roll forming machine precisely labels each formed product, ensuring efficient tracking and identification during production and shipment. |

|

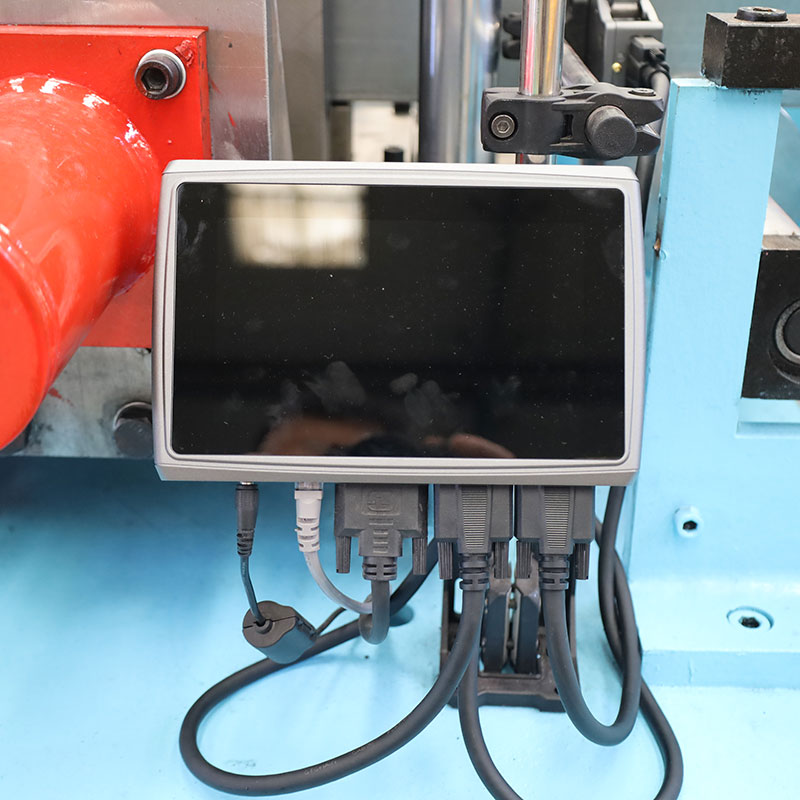

PLC control box

Our PLC control box seamlessly integrates with your roll forming machine, offering precise control and automation. Streamline operations, optimize production, and ensure consistent, high-quality output with ease. |

|

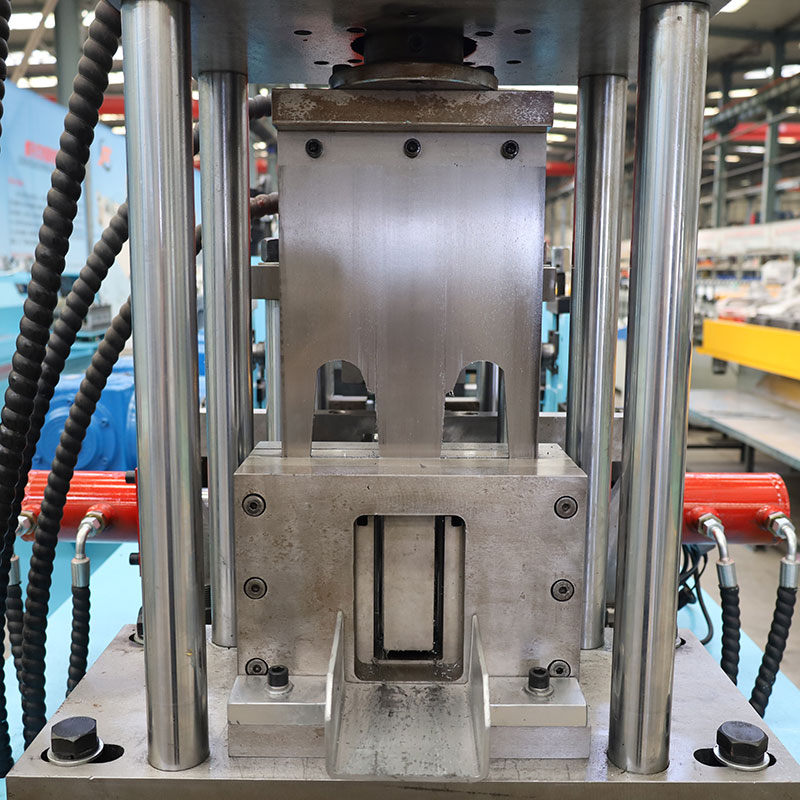

Cutting mode

hydraulic cutting, blade material: imported material: tungsten steel, hydraulic power: 5.5KW |

COMPANY INTRODUCTION OF Zhongke Top Hat Section Channel Machine

Zhongke Roll Forming Machine Factory has over 20 years of experience in manufacturing roll-forming machines, with a skilled team of 100 workers and a 20,000 square meters workshop. it is known for its high-quality machines, personalized services and fiexdble options, including custom design and manufacturing At Zhongke Roll Forming Machine Factory, they are committed to providing personalized and flexible services to meet the specific needs of so many clients, they offer custom design and manufacturing services, Their product range includes Light Gauge Building Steel Frame Roll Forming Machines, Glazed Tile Forming Machines, Roof Panel and Wall Panel Molding Machines, C/Z Steel Machines, and more. zhongke is passionate about their work and committed to exceeding clients' expectations. Hope you for considering Zhongke Roll Forming Machine Factory!

OUR CUSTOMERS OF Zhongke Top Hat Section Channel Machine

Our products are sold to many countries and regions all over theworld, and we have established long-term cooperative relations with clients!

PACKAGING & LOGISTICS OF Door Frame Roll Forming Machine

FAQ

Q1: How to play order?

A1:Inquiry---Confirm the profile drawings and price ---Confirm Thepl---Arrange the deposit or L/C---Then ok

Q2: How to visit our company?

A2: Fly to Beijing airport: By high speed train from Beijing Nan to Cangzhou Xi(1 hour),then we will pick you up.

Fly to Shanghai Hongqiao airport:By high speed train from Shanghai Hongqiao to Cangzhou Xi(4 hour),then we will pick you up.

Q3: Are you manufacturer or trading company?

A3: We are manufacturer and trading company .

Q4: Do you provide installing and training overseas?

A4: Overseas machine install and worker training services are optional.

Q5: How is your after sales support?

A5: We provide technical support on line as well as overseas services by skillful technicians.

Q6: How does your factory do regarding quality control?

A6: There is no tolerance regarding quality control. Quality control complies with ISO9001. Every machine has to past testing running before it's packed for shipment.

Q7: How can I trust you that machines pasted testing running before shipping?

A7: (1) We record the testing video for your reference. Or,

(2) We welcome your visit us and test machine by yourself in our factory

Q8: Do you sell only standard machines?

A8: No. Most machines are customized.

Q9: Will you deliver the right goods as ordered? How can I trust you?

A9: Yes, we will. We are Gold supplier of Made-in-China with SGS assessment (Audit report can be provided).