ZKRFM JCH New Roll Forming Machine for Floor Roof Colored Steel Tile for Home Use Manufacturing Plant Core Motor Engine Components

Product descriptions from the supplier Overview

PRODUCT DESCRIPTION OF Jch Roof Panel Roll Forming Machine

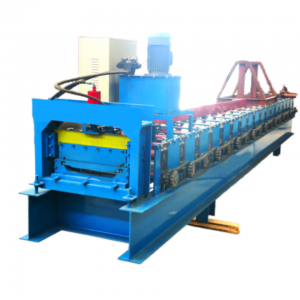

The Jch Roof Panel Roll Forming Machine T is a specialized equipment designed for the efficient production of high-quality roof panels. Its primary function is to transform flat metal sheets into custom-shaped roofing profiles, tailored to meet various architectural and structural requirements. The machine integrates advanced roll-forming technology with precise control systems, ensuring accurate and consistent panel formation. The production line is streamlined for maximum efficiency, allowing for rapid output of roof panels suitable for residential, commercial, and industrial applications. The JCH Roof Panel Roll Forming Machine offers versatility in material handling and panel design, making it an ideal solution for manufacturers seeking to expand their roofing product offerings.

| Type | Tile Forming Machine |

| Tile Type | Colored Steel |

| Use | FLOOR |

| Production Capacity | 8-12m/min |

| Place of Origin | China |

| - | Hebei |

| Brand Name | zhongke |

| Voltage | 380V 50Hz 3phases |

| Dimension(L*W*H) | 6500*1300*1100 |

| Weight | 5kg |

| Warranty | 1 Year |

| Key Selling Points | Long Service Life |

| Rolling thinckness | 0.3-0.8mm |

| Feeding width | 1000mm |

| Machinery Test Report | Provided |

| Video outgoing-inspection | Provided |

| Marketing Type | New Product 2024 |

| Warranty of core components | 1 Year |

| Core Components | Motor, Engine |

PURLIN SPECIFICATIONS OF Jch Roof Panel Roll Forming Machine

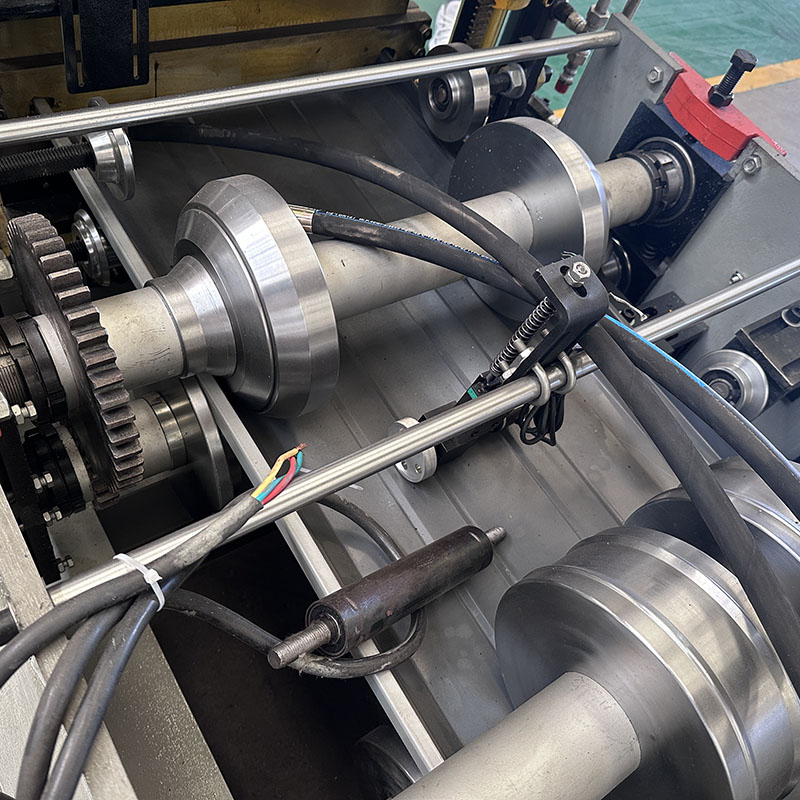

1.High-Quality Construction: The Low Price Automatic Cold Panel Metal Steel Building Material Machinery Deck Making Floor Decking Roll Forming Machine is built with robust Cr12 steel rollers and shafts, ensuring lasting durability for continuous operation and hassle-free performance.

2.Advanced Control System: The machine features a Taiwan Delta control system, allowing for precise adjustments and smooth operation, minimizing errors and maximizing productivity.

3.Cutting Efficiency: Boasting an automatic hydraulic cutting system, the machine guarantees efficient, accurate, and high-speed production, providing significant time savings and minimizing material waste.

4.Comprehensive Application: Suitable for various industries including hotels, building material shops, manufacturing plants, restaurants, and more, the machine is versatile and easily adaptable to different production needs.

5.Comprehensive Warranty and Technical Support: Trust in the RFM brand for 1-year coverage on core components and a 1-year warranty period, ensuring peace of mind during your investment. Additionally, benefit from instructional operation videos, marketing materials, and technical service support.

MACHINE DETAILS OF Jch Roof Panel Roll Forming Machine

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

COMPANY INTRODUCTION OF Roof Sheet Roll Forming Machine

Zhongke Roll Forming Machinery Plant boasts over two decades of expertise in crafting roll-forming equipment, bolstered by a proficient workforce of 100 craftsmen and a sprawling 20,000 square meter production facility. Renowned for their premium machinery, tailored services, and adaptable solutions, they specialize in customized designs and fabrication. At Zhongke, they are dedicated to offering individualized and flexible services tailored to the unique requirements of diverse clients. Their comprehensive product portfolio encompasses Light Gauge Steel Framing Roll Formers, Glazed Tile Production Lines, Roof & Wall Panel Molding Machines, C/Z Purlin Roll Formers, and more. With a relentless pursuit of excellence and a steadfast commitment to surpassing client expectations, Zhongke Roll Forming Machinery Plant invites your consideration.

OUR CUSTOMERS OF Roof Sheet Roll Forming Machine

Our products are sold to many countries and regions all over theworld, and we have established long-term cooperative relations with clients!

PACKAGING & LOGISTICS OF Door Frame Roll Forming Machine

FAQ

1. who are we?

We are based in Hebei, China, start from 2016,sell to Domestic Market(80.00%),South Asia(10.00%),Africa(10.00%). There are total about 11-50 people in our office.

2. how can we guarantee quality?

Always a pre-production sample before mass production;

Always final Inspection before shipment;

3.what can you buy from us?

Light Gauge Buildings Steel Frame (LGBSF) Roll Forming Machine, Roll Forming Machine, Glazed Tile Forming Machine, Roof Panel Wall Panel Molding Machine, C/Z Steel Machine.

4. why should you buy from us not from other suppliers?

Our factory is a professional Roll Forming Machine manufacturer with 17 years experience,

we have 100 well trained workers and 20,000 (square meters) workshops.

5. what services can we provide?

Accepted Delivery Terms: FOB,CFR,EXW,FAS,FCA,DDP,DAF;

Accepted Payment Currency: USD,EUR,JPY,CAD,AUD,HKD,GBP,CNY,CHF;

Accepted Payment Type: T/T,L/C,D/P D/A,MoneyGram,Credit Card,PayPal,Western Union,Cash,Escrow;

Language Spoken: English,Chinese,Spanish,Japanese,Portuguese,German,Arabic,French,Russian,Korean,Hindi,Italian