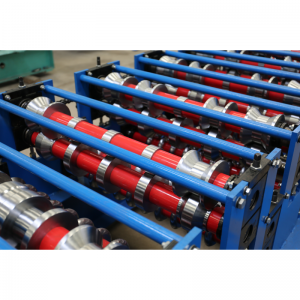

Zhongke Corrugated and Trapezoid Roofing Tile Roll Forming Machine Double Layers Metal Steel Sheets Roofing Machine Tile Making Machine

Advantages of using a double layer roll forming machine

If you are in the business of manufacturing sheet metal or other materials, a double-layer roll forming machine may be the perfect addition to your production line. This type of roll forming machine is designed to produce sheet metal in two different profiles simultaneously, making it an efficient and cost-effective solution for manufacturers.

One of the main advantages of using a two-layer roll forming machine is the ability to increase productivity. By producing two different profiles simultaneously, manufacturers can effectively double production without having to invest in additional machinery. This can result in significant cost savings and increased productivity.

In addition to increased productivity, double-layer rollformers offer greater manufacturing flexibility. With the ability to produce two different profiles, manufacturers are able to meet a wider range of customer needs. This means they can take on a variety of projects and increase business opportunities.

In addition, double-layer roll forming machines can help save valuable floor space in manufacturing facilities. Instead of having a separate machine for each profile, manufacturers can consolidate their production lines and reduce the overall equipment footprint. This can save money on rent or construction costs.

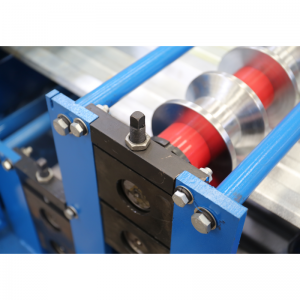

Another benefit of using a double-layer roll forming machine is improved product quality. With the ability to produce two different profiles simultaneously, manufacturers can ensure their products are built to the highest standards. This can improve customer satisfaction and enhance market reputation.

Overall, two-layer roll forming machines offer manufacturers numerous advantages in terms of productivity, flexibility, space efficiency and product quality. By investing in such machinery, manufacturers can succeed in the highly competitive market.