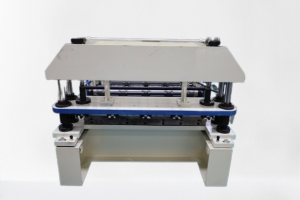

Triple Layer Roll Forming Machine Three Layer Roll Forming Machine Three Layer Roll Forming Machine

Title: Efficiency of three-layer roll forming machines

Roll forming machines have changed the game in manufacturing. They significantly improve the production efficiency of a variety of metal products, including roof panels, wall panels and flooring. One of the most advanced and efficient roll forming machines on the market today is the three-layer roll forming machine.

The three-layer roll forming machine is designed with three sets of rolling tools, which can produce three different profiles at the same time. This advanced technology enables manufacturers to maximize production and save valuable floor space. The machine is equipped with multiple punching devices to achieve precise and efficient production.

Three-layer roll forming machines are versatile and can be customized to meet specific production requirements. Able to produce multiple profiles simultaneously, it is extremely flexible and ideal for manufacturers requiring a variety of products. The machine can switch seamlessly between different profiles, reducing downtime and increasing overall productivity.

Additionally, three-layer roll forming machines provide superior precision and consistency in product quality. The machine's advanced control system and automated processes ensure that each profile produced is accurate and uniform. This is critical to meeting strict quality standards and customer expectations.

In addition, the three-layer roll forming machine is designed to be easy to operate and maintain. It comes with user-friendly controls and has a rugged construction for long-term reliability. With proper training and routine maintenance, manufacturers can optimize the performance of their machines and extend their service life.

In summary, a three-layer roll forming machine is a valuable investment for manufacturers looking to increase production capabilities. Its advanced technology, versatility, precision and efficiency make it the first choice for the production of various metal profiles. As the manufacturing industry continues to evolve, investing in innovative machines such as three-layer roll forming machines is critical to staying competitive and meeting market demands.