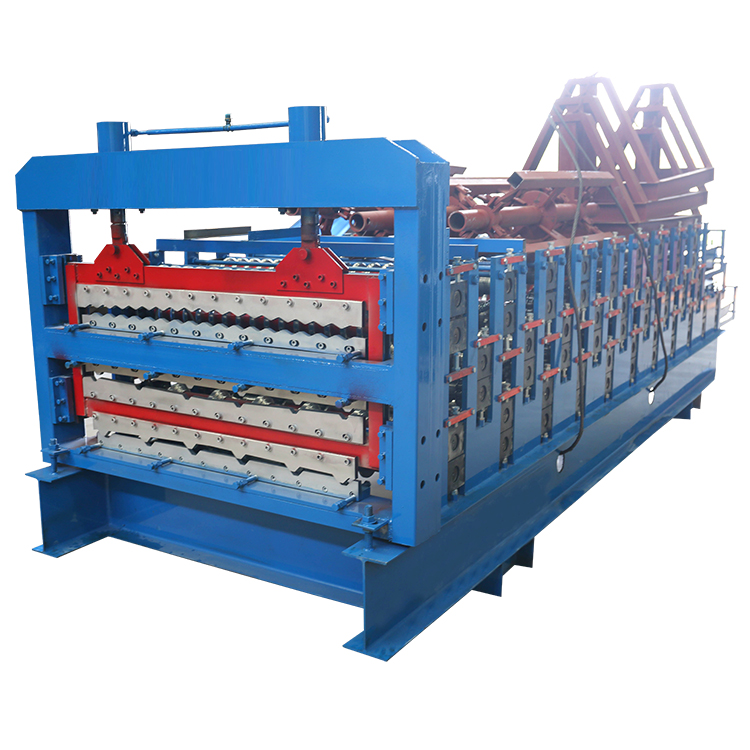

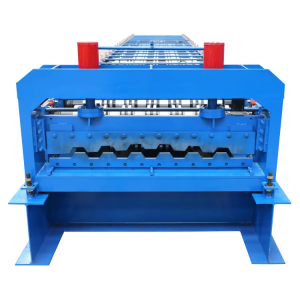

Triple Layer Roll Forming Machine Corrugated Roll Forming Machinery Trapezoidal Roofing Roll Forming Machine

PRODUCT DESCRIPTION

|

High quality glazed tile IBR sheet double layer trapezoidal roof press making machine roll forming machinery |

||

| Formed Material | PPGI,GI,AI | Thickness:0.3-0.7mm , as custom order |

| Decoiler | Hydraulic decoiler | Manual decoiler(will give you as free) |

| Main body | Roller station | 14 rows as profile |

| Diameter of shaft | 75mm | |

| Material of rollers | 45# Steel with heat treatment | |

| Machine body frame | 400 H Steel 10mm | |

| Drive | Double Chain transmission | |

| Dimension(L*W*H) | 7.5*1.3*1.5M | |

| Weight | 4.5T | |

| Cutter | Automatic | cr12mov material, no scratches, no deformation |

| Power | Main Power | 5.5KW Siemens Brand |

| Voltage | 380V 50Hz 3Phase | As your requirement |

| Control system | Electric Box | Customized(famous brand) |

| Language | English(Support multiple languages) | |

| PLC | Automatic production of the whole machine. Can set batch, length, quantity, etc. | |

| Forming Speed | 15-30m/min | The speed depends on the shape of the tile and the thickness of the material. |

Production Flow

Customer Visiting

Certifications

Selling Point

1.Efficient and Reliable: The ZKRFM U-Shaped Keel Roll Forming Machine is designed to efficiently produce steel purlin for various industries, including construction, garment shops, and manufacturing plants. With a production capacity of 15m/min, it ensures reliability in meeting the demands of customers.

2.Easy to Operate: The machine is user-friendly and easy to operate, making it accessible to a wide range of users. It requires minimal training and can be operated by individuals with basic technical knowledge.

3.Versatile: The ZKRFM Purlin Roll Forming Machine can work with a variety of materials, including PPGI, PPGL, GI, and GL. It also allows for adjustments in the rolling thickness, from 0.3-0.8mm, to cater to different customer needs.

4.Durable Construction: The machine is built with high-quality materials, such as 45# steel, Chrome Plated, Cr 12 High Grade Steel, and High Grade No.45 Forged. This ensures a long lifespan and minimal maintenance requirements.

5.Comprehensive After-Sales Service: In addition to a one-year warranty, the manufacturer provides after-sales service, including video technical support, and engineers available to service machinery overseas. This ensures customer satisfaction and minimizes downtime.

FAQ

1. who are we?

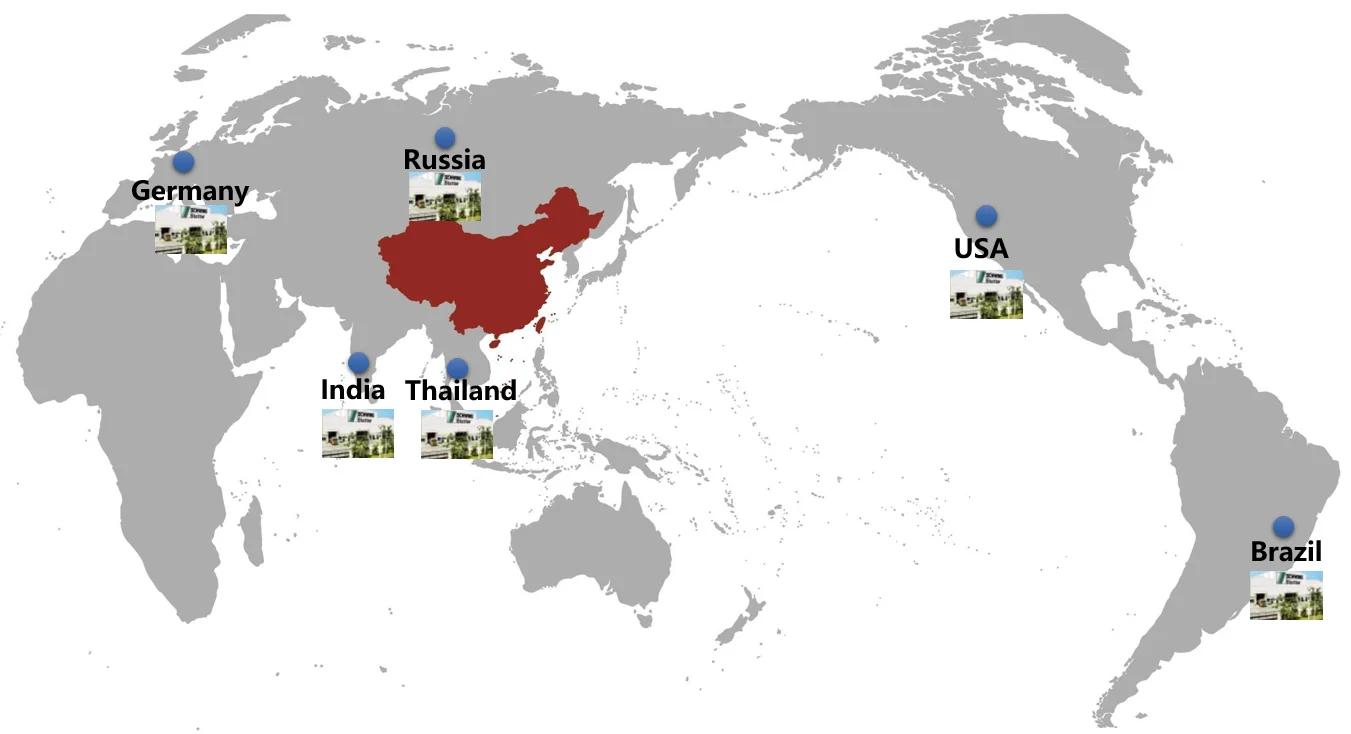

We are based in Hebei, China, start from 2016,sell to Domestic Market(80.00%),South Asia(10.00%),Africa(10.00%),Eastern Asia(0.00%),North America(0.00%),South America(0.00%),Oceania(0.00%),Western Europe(0.00%),Southern Europe(0.00%),Central America(0.00%),Northern Europe(0.00%),Eastern Europe(0.00%),Mid East(0.00%),Southeast Asia(0.00%). There are total about 11-50 people in our office.

2. how can we guarantee quality?

Always a pre-production sample before mass production;

Always final Inspection before shipment;

3.what can you buy from us?

Light Gauge Buildings Steel Frame (LGBSF) Roll Forming Machine, Roll Forming Machine, Glazed Tile Forming Machine, Roof Panel Wall Panel Molding Machine, C/Z Steel Machine

4. why should you buy from us not from other suppliers?

Our factory is a professional Roll Forming Machine manufacturer with 17 years experience,

we have 100 well trained workers and 20,000 (square meters) workshops.

5. what services can we provide?

Accepted Delivery Terms: FOB,CFR,EXW,FAS,FCA,DDP,DAF;

Accepted Payment Currency: USD,EUR,JPY,CAD,AUD,HKD,GBP,CNY,CHF;

Accepted Payment Type: T/T,L/C,D/P D/A,MoneyGram,Credit Card,PayPal,Western Union,Cash,Escrow;

Language Spoken: English,Chinese,Spanish,Japanese,Portuguese,German,Arabic,French,Russian,Korean,Hindi,Italian