Trapezoidal Single Layer Roll Forming Machine

PRODUCT DESCRIPTION OF Zhongke Trapezoidal Single Layer Roll Forming Machine

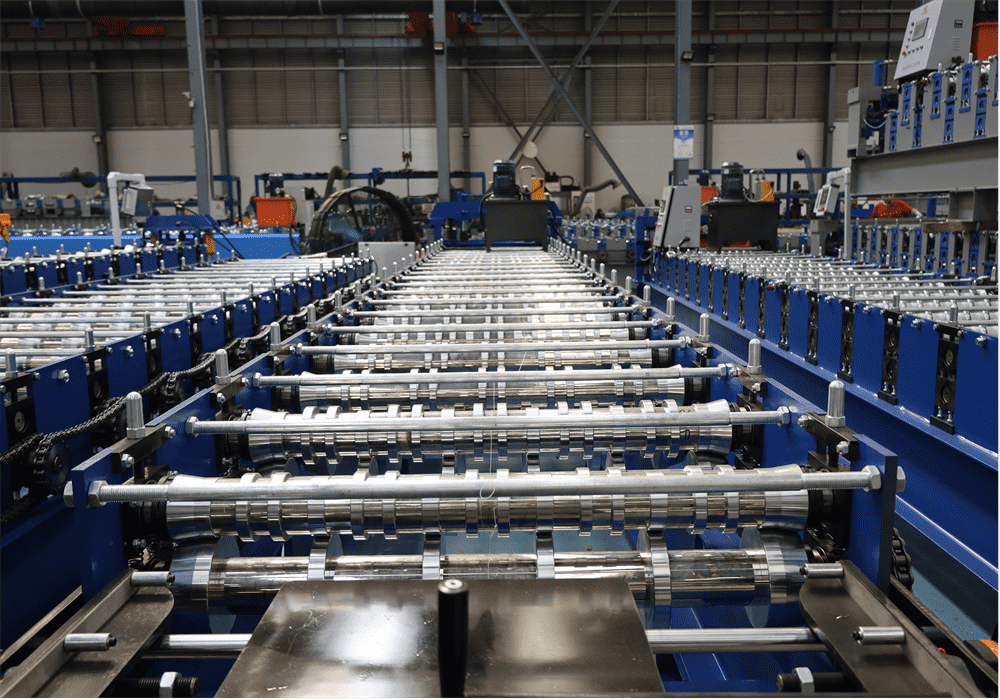

The Zhongke Trapezoidal Single Layer roll forming machine

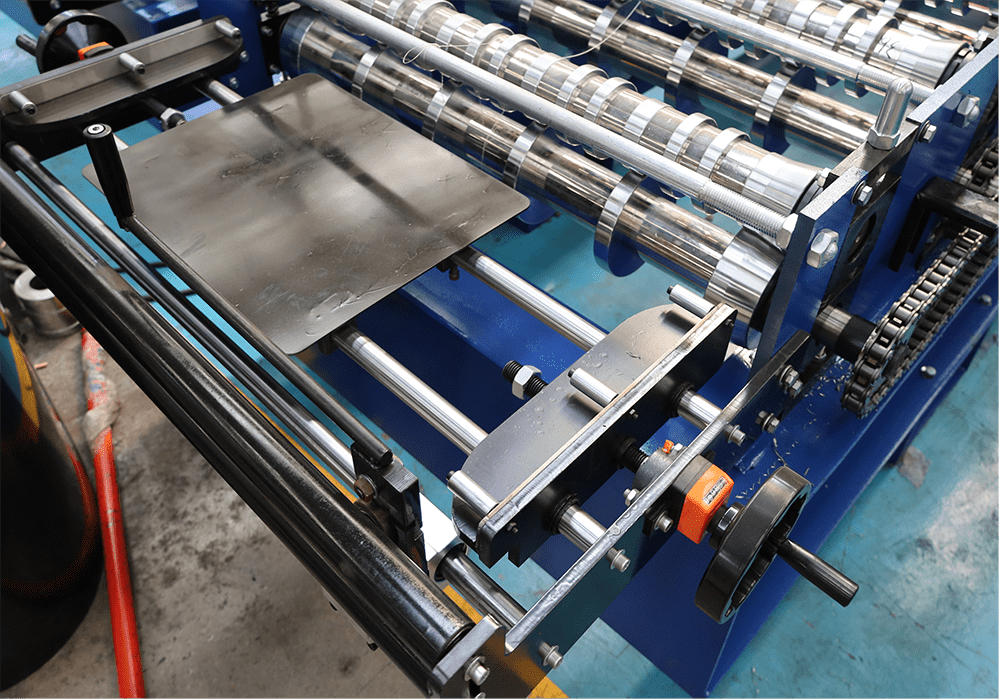

1. The blade only has cr12mov, which is of good quality, strong and wear-resistant.

2. The chain and middle plate are widened and thickened, and the production performance is more stable.

3. The wheel adopts overtime electroplating, and the coating reaches +0.05 mm.

4. The whole machine adopts shot blasting machine to remove rust, and spray both sides of the primer and the two sides of the topcoat to strengthen the adhesion of the machine to the paint, not only beautiful in appearance, but also not easy to wear.

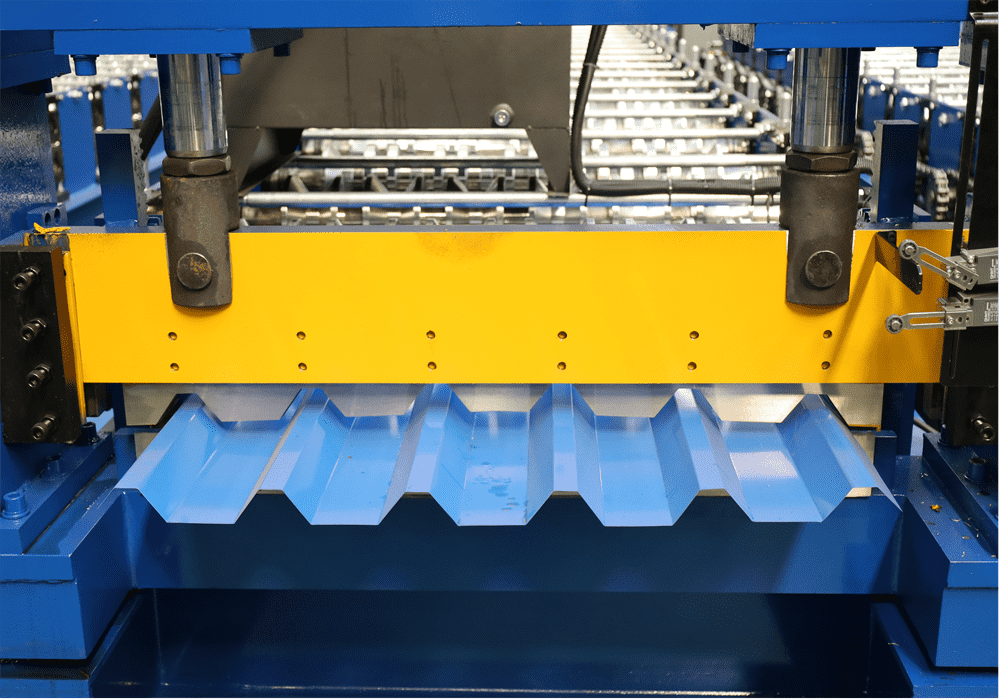

PURLIN SPECIFICATIONS OF Zhongke Trapezoidal Single Layer Roll Forming Machine

| Strip width | 1200mm. |

| Strip thickness | 0.3mm-0.8mm. |

| Steel coil inner diameter | φ430~520mm. |

| Steel coil outer diameter | ≤φ1000mm. |

| Steel coil weight | ≤3.5 tons. |

| Steel coil material | PPG |

MACHINE DETAILS OF Zhongke Trapezoidal Single Layer Roll Forming Machine

COMPANY INTRODUCTION OF Zhongke Trapezoidal Single Layer Roll Forming Machine

For two decades, Zhongke Rolling Machinery Factory has been deeply rooted in the fertile ground of rolling technology, bringing together a team of over a hundred master craftsmen. Our modern facility spans over 20,000 square meters, equipped with state-of-the-art machinery, painting a grand picture of industrial manufacturing excellence.

We are renowned for our high-end machinery, personalized service approach, and flexible solutions tailored to meet diverse client needs. Specializing in transforming client visions into unique masterpieces, whether it's lightweight yet robust steel structures, or the fusion of classical and contemporary beauty in glazed roof tiles, we provide comprehensive solutions for roofing and wall cladding applications, as well as efficient C/Z-type steel production lines. With a rich and diverse product portfolio, Zhongke skillfully crafts the colorful dreams of the architectural world.

Driven by passion, we strive to exceed expectations with every project, ensuring that every collaboration is marked by outstanding achievement. Today, we extend a warm invitation to join forces with Zhongke on a journey of innovation and excellence, opening a new chapter of partnership and creating a brilliant future together.

OUR CUSTOMERS OF Zhongke Double Layer Roll Forming Machine

PACKAGING & LOGISTICS OF Zhongke Double Layer Roll Forming Machine

FAQ

Q1: How to play order?

A1:Inquiry---Confirm the profile drawings and price ---Confirm Thepl---Arrange the deposit or L/C---Then ok

Q2: How to visit our company?

A2: Fly to Beijing airport: By high speed train from Beijing Nan to Cangzhou Xi(1 hour),then we will pick you up.

Fly to Shanghai Hongqiao airport:By high speed train from Shanghai Hongqiao to Cangzhou Xi(4 hour),then we will pick you up.

Q3: Are you manufacturer or trading company?

A3: We are manufacturer and trading company.Had very greatful experience.

Q4: Do you provide installing and training overseas?

A4: Overseas machine install and worker training services are optional.

Q5: How is your after sales support?

A5: We provide technical support on line as well as overseas services by skillful technicians.

Q6: How does your factory do regarding quality control?

A6: There is no tolerance regarding quality control. Quality control complies with ISO9001. Every machine has to past testing running before it's packed for shipment.

Q7: How can I trust you that machines pasted testing running before shipping?

A7: (1) We record the testing video for your reference. Or,

(2) We welcome your visit us and test machine by yourself in our factory

Q8: Do you sell only standard machines?

A8: No. Most machines are customized.