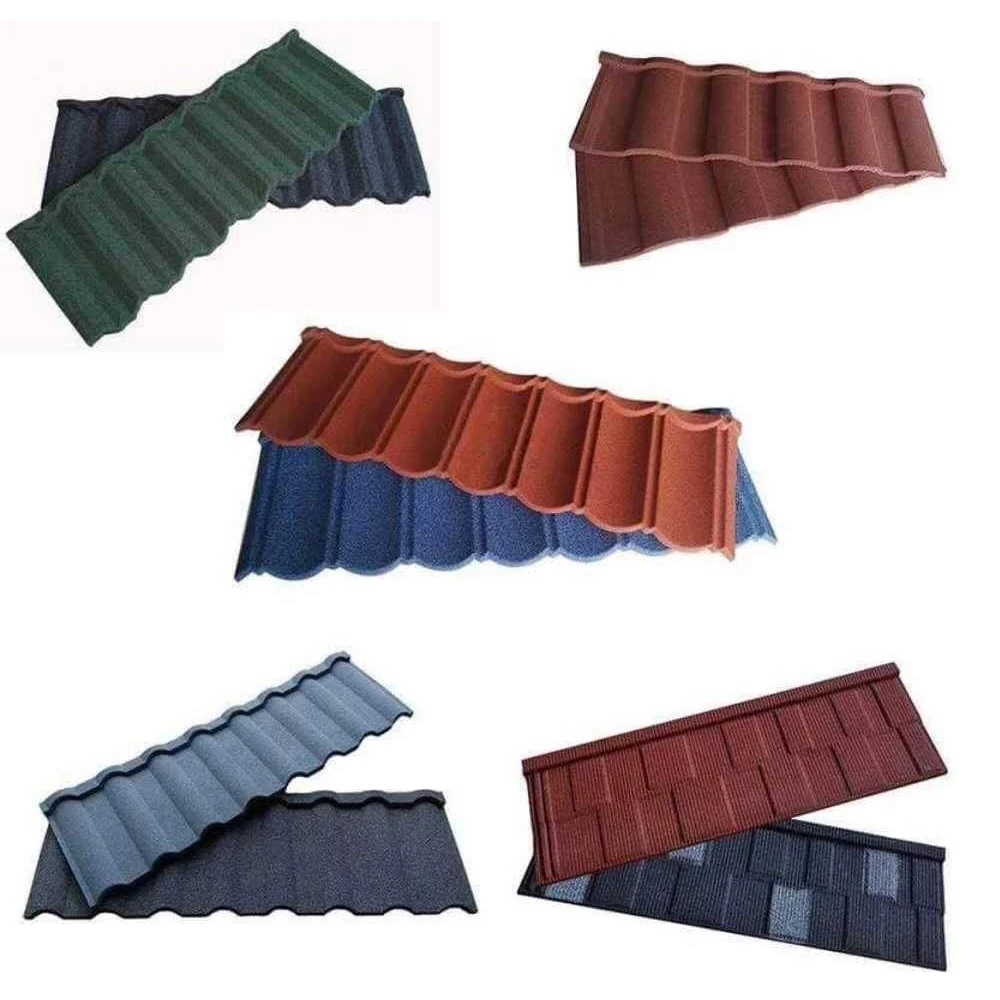

Sales Hot Color Stone Coated Steel Roof Forming Machine Sand Blast Production Line

PRODUCT SPECIFICATIONS

| No | Item | Data |

| 1 | Automatic spray bottom dispensing machine | 4000*1350*1600 mm |

| 2 | Automatic sand blasting machine | 3000*1850*900 mm |

| 3 | First drying oven | 18000*850*1200 mm |

| 4 | Automatic spray surface glue | 3000*1650*900 mm |

| 5 | Second drying oven | 24000*850*1200 mm |

1.Production ability : Production speed:4000-7000 pcs/day

2.Machine weight: 20 MT

3.Total installed capacity: 100 kilowatts; AC 380V 50 HZ

4.Steel plate thickness: 0.2-0.6 mm

5.Steel plate width: 1000 mm-1450 mm

6.Product condition: Plant area 2000 square meters(25 meters*80 meters),mainframe product environment temperature above 20P

7.Production line characteristics: Horizontal, continuous product, stepless frequency conversion variable speeds,

PLC control, having reliable performances, easy operation.

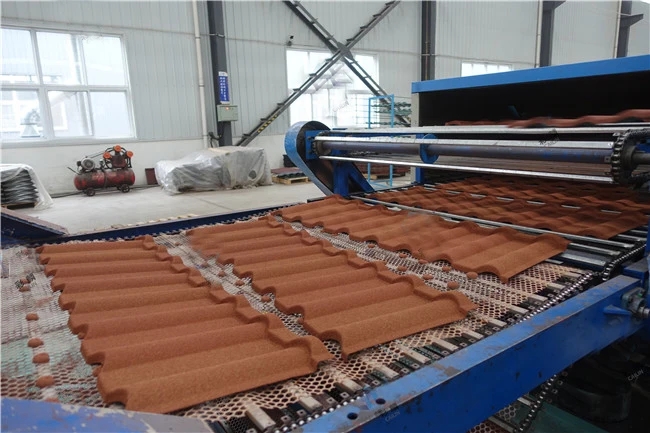

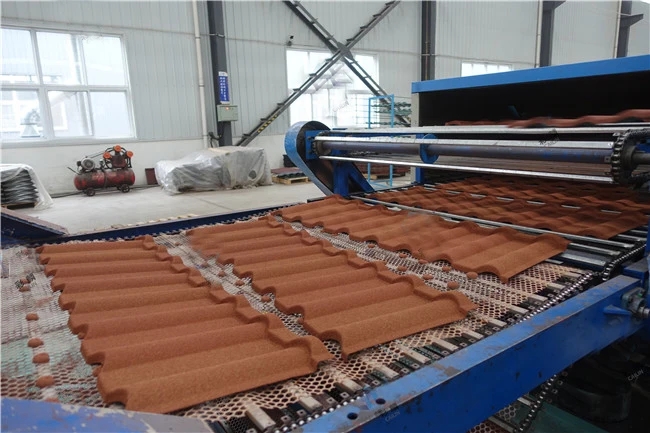

Details Images

Hydraulic press

The 315-ton color stone metal tile stamping hydraulic press is a special equipment for stamping and stretching of the color stone metal tile substrate. The fuselage design adopts a three-beam four-column structure. The equipment is composed of a fuselage, an oil cylinder, a stroke limit device, and a mold. The structure is simple, economical and practical.

Glue spray

Automatic primer spraying equipment (closed automatic glue spraying system) Structure: channel steel, welded Transmission device: 2.2 kilowatt variable Conveying device: reciprocating chain conveyor adjustment range, 0.1-0.6MPa Automatic glue gun: 4 sets Glue gun: 5 sets Glue gun holder: 1 set

Sand blasting

Automatic sandblasting room: 1 set Dimensions: 3000×1850×700 unit mm length×height×width Structure: channel steel, angle steel, welded Transmission device: with glue spraying equipment, chain compound transmission Automatic sand bucket: 1 set 550×600×500 Automatic lifting machine: 1 set, lifting height 1.9 meters, power 300 kg/hour Sandblasting gun: 4 sets.

Drying oven

drying roomStructure: Welded by carbon steel Frame insulation wall: 30 meters, 1 mm thick cold plate bending forming insulation cotton filling. Infrared heating tube: 50 pieces Automatic temperature controller: 2 sets of temperature adjustment range 0-160° Cooling device: 1 set

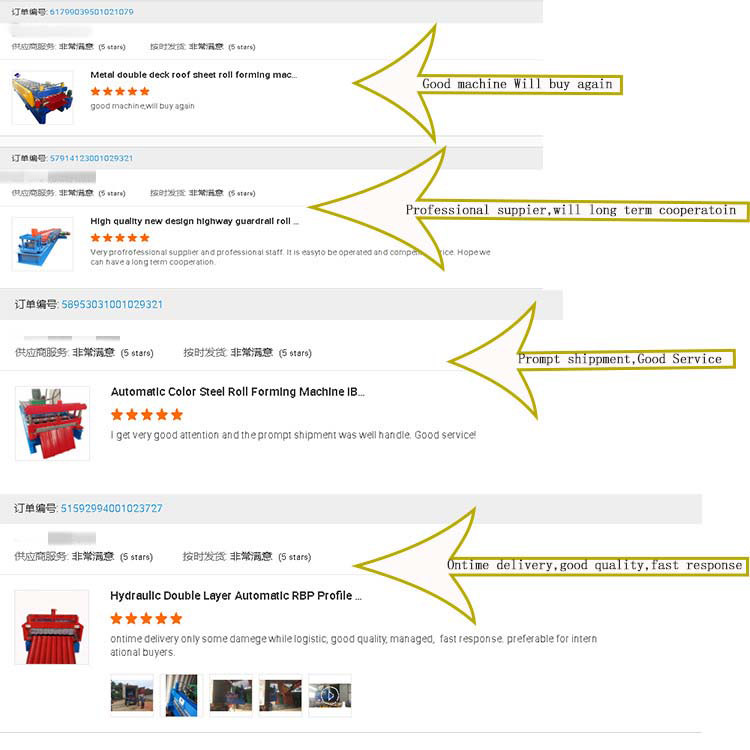

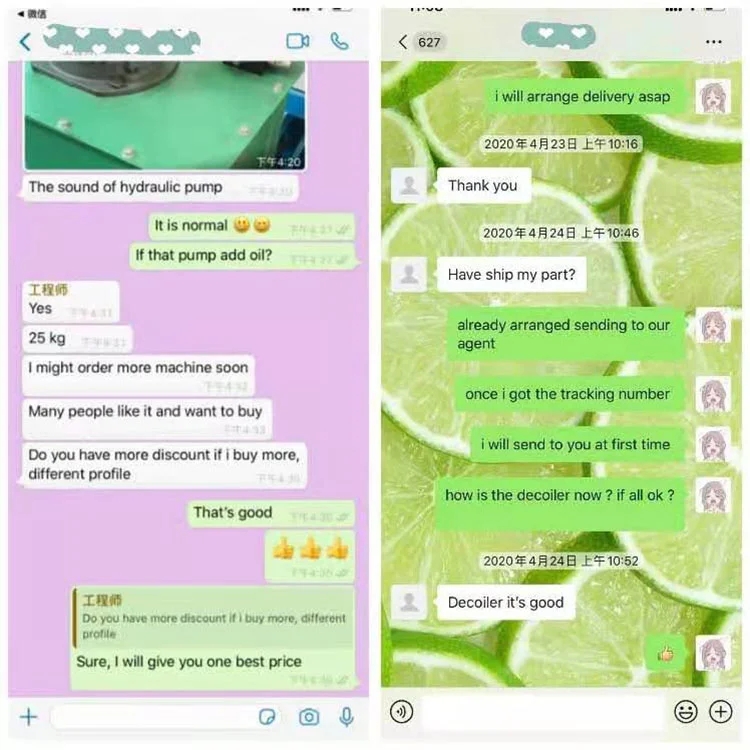

Successful Project

Project in Thailand

Project in India

Project in Russia

Company Profile

Zhongke Forming machine Machine Factory is located in China's machinery and castine townshin-- Rotou City. It is well located with Retiine and Tianiin in the north and Rohal Sea in the east Boton Citv has develoned consenient and multifunctional traffic lines. The main transport lines in Botou are: BeijingShanahai Rathway evnresswavs and to4 national road Zhoneke is a manufacturer of forming machine machines, we have many years of R & D, design and productior of rich industry experience. Nowadavs, our company has formed a complete modern management model with great nroduct develonment and innovation abilitv Our products are favored by global customers because of the lightweight structure, novel design and hieh degree of innovation.After years of practical experience accumulation and industry experts design layout, Our company in product production, sales, installation, commissioning and nrosdde technleal eoneslestion of formins mschine hae arest sdsrantaneel Our factory is a modern enterprise with strong technical strength and production canacity. Our Comnany nroducts rely on hieh ouality and low nrice and good technical nerformance in the customer hase to harvest enod feedhackl And we can also accordtne to user reouirements for snecial desien andl manufacturina at the same time tn the nroduction tnstallation commiesionino and maintenance of color steel equipment for users to provide one-stop service and technlcal guldance.

FAQ

1. who are we?

We are based in Hebie, China, start from 2010,sell to Africa(20.00%),Domestic Market(20.00%),Southeast Asia(15.00%),South America(10.00%),North America(5.00%),Eastern Europe(5.00%),Oceania(5.00%),Mid East(5.00%),Central America(5.00%),South Asia(5.00%),Eastern Asia(2.00%),Western Europe(2.00%),Southern Europe(00.00%). There are total about 51-100 people in our office.

2. how can we guarantee quality?

Always a pre-production sample before mass production;

Always final Inspection before shipment;

3.what can you buy from us?

Roof Sheet Roll Forming Machine,Wall Panel Roll Forming Machine,Highway Guardrail Plate Forming Machine,Floor Decking Sheet Rolling Machine,C Purlin Making Machine

4. why should you buy from us not from other suppliers?

1.Rich experience 2.High-quality after-sales service system 3.Brand and Qualification Guarantee 4.Technological innovation advantage

5. what services can we provide?

Accepted Delivery Terms: FOB,CFR,CIF,EXW,FAS,CIP,FCA,CPT,DEQ,DDP,DDU,Express Delivery,DAF,DES;

Accepted Payment Currency:USD,EUR,JPY,CAD,AUD,HKD,GBP,CNY,CHF;

Accepted Payment Type: T/T,L/C,D/P D/A,MoneyGram,Credit Card,PayPal,Western Union,Cash,Escrow;

Language Spoken:English,Chinese,Spanish,Japanese,Portuguese,German,Arabic,French,Russian,Korean,Hindi,Italian