Products

-

Zhongke new rolling shutter door forming machine

The rolling shutter door forming machine adopts a reverse synchronous operation process, with high automation, low labor intensity, simple operation, stable equipment operation, no noise, no pollution, adjustable product specifications, and multiple uses for one machine.

-

New machine Australian roller shutter door forming machine

Australian roller shutter door forming machine adopts a reverse synchronous operation process, with high automation, low labor intensity, simple operation, stable equipment operation, no noise, no pollution, adjustable product specifications, and multiple uses for one machine.

-

Type 730 multi-wave glazed tile molding equipment

Type 730 multi-wave glazed tile molding equipment is equipment used to produce glazed tiles. It usually consists of a feeding device, a forming system and cutting equipment. Through mold shaping and pressing, the raw materials can be processed into glazed tile products with specific shapes and textures. The machine has the characteristics of automated production, efficient processing and good product consistency, meeting the construction industry’s demand for glazed tile products.

Support customization

Any inquiries we are happy to reply, pls send your questions and orders -

765 Large Wave Glazed Tile Forming Machine

765 Large Wave Glazed Tile Forming Machine is equipment used to produce glazed tiles. It usually consists of a feeding device, a forming system and cutting equipment. Through mold shaping and pressing, the raw materials can be processed into glazed tile products with specific shapes and textures. The machine has the characteristics of automated production, efficient processing and good product consistency, meeting the construction industry’s demand for glazed tile products.

-

750 type guide column arc glazed tile molding equipment

750 type guide column arc glazed tile molding equipment is equipment used to produce glazed tiles. It usually consists of a feeding device, a forming system and cutting equipment. Through mold shaping and pressing, the raw materials can be processed into glazed tile products with specific shapes and textures. The machine has the characteristics of automated production, efficient processing and good product consistency, meeting the construction industry’s demand for glazed tile products.

-

700 glazed tile forming machine

700 Large Wave Glazed Tile Forming Machine is equipment used to produce glazed tiles. It usually consists of a feeding device, a forming system and cutting equipment. Through mold shaping and pressing, the raw materials can be processed into glazed tile products with specific shapes and textures. The machine has the characteristics of automated production, efficient processing and good product consistency, meeting the construction industry’s demand for glazed tile products.

Support customization

Any inquiries we are happy to reply, pls send your questions and orders -

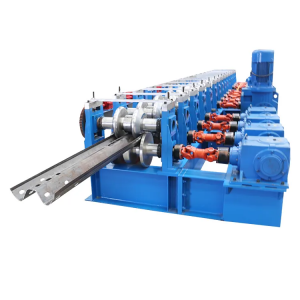

New Steel Frame & Purlin Corner Column Forming Equipment with Motor Pump Gear PLCEngine Bearing for Machinery Repair Shops

1、Marketing Type:Hot Product 2024

2、Warranty of core components:2 years

3、Core Components:PLC, Engine, Bearing, Gearbox, Motor, Pressure vessel, Gear, Pump

4、Condition:New

5、Work Pressure:380V or as required -

Automatic Steel Frame & Purlin Corner Column Forming Equipment Motor Pump Gear PLCEngine Bearing Efficient Machinery Repair

Purlin corner molding equipment is an efficient and accurate manufacturing tool for the production of purlins and corner posts used in construction and structural engineering. It uses advanced molding technology to process sheet metal quickly and accurately into the desired shape and size. The equipment is automated to improve productivity and consistency.We also provide customized services and professional technical support and after-sales service.

-

Automatic 2-Wave Expressway Highway Guardrail Crash Barrier Roll Forming Machine for Building Construction PLC Control System

1、Suitable material:10 ton hsolor steel coils, 0.3-0.7mm, 1220&1450mm coil width

2、Forming speed:About 10-15m/min

3、Hydraulic station power:5.5 KW(depend on final design)

4、Material of forming rollers:No.45 steel,plated with chrome on surface

5、Main motor power:55kw(depend on final design) -

ZKRFM New and Used Highway Guardrail Roll Forming Machine for Tile Building with PLCEquipped with Reliable Gear and Bearing

1、Material of rollers:45# steel, hard chrome plated on the surface

2、Machine body frame:350 H steel

3、Drive:one Chain transmission

4、Dimension(L*W*H):10*1.0*1.7 m

5、Weight:5T -

ZKRFM Used Galvanized Steel Profile Metal Plate Cold Bending Roll Forming Machine for Tile Protection and Highway Guardrail

Highway guardrail roll forming is an efficient automation device that can quickly produce a large number of highway guardrail profiles. It adopts advanced rolling molding process to ensure that the output guardrail size is accurate and the shape is consistent. The forming machine can adapt to different specifications and shapes of guardrail production, with a high degree of flexibility and versatility. In addition, it also has the advantages of automatic operation, safety and reliability.We also provide customized services and professional technical support and after-sales service.

-

ZKRFM U Purlin Forming Machine U Channel Roll Forming Machine U Profile Roll Forming Machine

1、Hydraulic decoiler:Manual decoiler(will give you as free)

2、Roller station:14rows(As your requirement)

3、Diameter of shaft:50mm solid shaft

4、Material of rollers:45# steel, hard chrome plated on the surface

5、Machine body frame:350 H steel