Photovoltaic bracket 50-200 C shape forming machine

Product descriptions from the supplier

Overview

PRODUCT DESCRIPTION OF Zhongke Rolling Shutter Door Roll Formimg Machine

Photovoltaic bracket molding machine, as an efficient production equipment in the field of new energy, is designed to meet the needs of the rapid development of the photovoltaic industry. This machine integrates advanced technology and exquisite technology, can realize the rapid and accurate molding of photovoltaic bracket, greatly improve production efficiency and product quality. Intelligent control system, easy operation, low maintenance cost, to ensure long-term stable operation. Its excellent adaptability and flexibility can meet the production needs of photovoltaic brackets of different specifications and different materials, helping enterprises to seize market opportunities and achieve green transformation and sustainable development. Choosing our photovoltaic bracket forming machine is to choose an efficient, reliable and environmentally friendly production partner to create a new brilliance in the photovoltaic industry!

PRODUCT DESCRIPTION

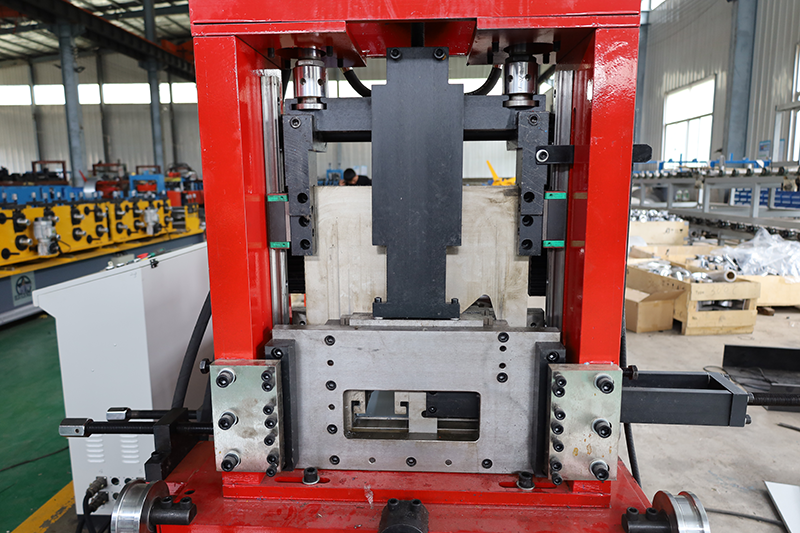

| item | Photovoltaic bracket roll forming machine |

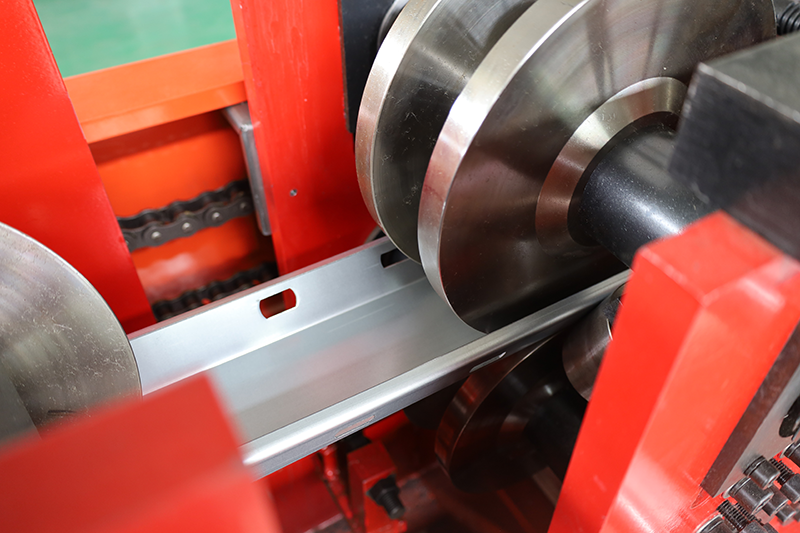

| Suitable to process | Color alu-zinc steel coil |

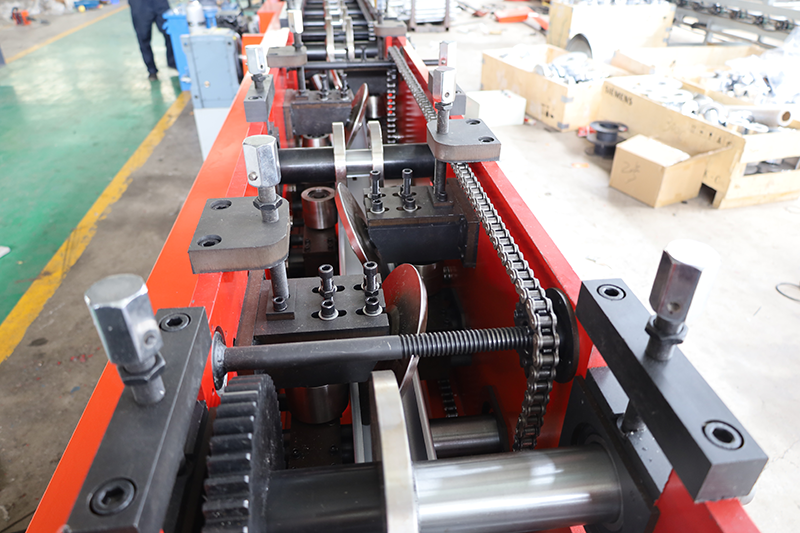

| Roller | 12Rows |

| Dimensions | 7*1.6*1.8m |

| Motor Power | 5Kw |

|

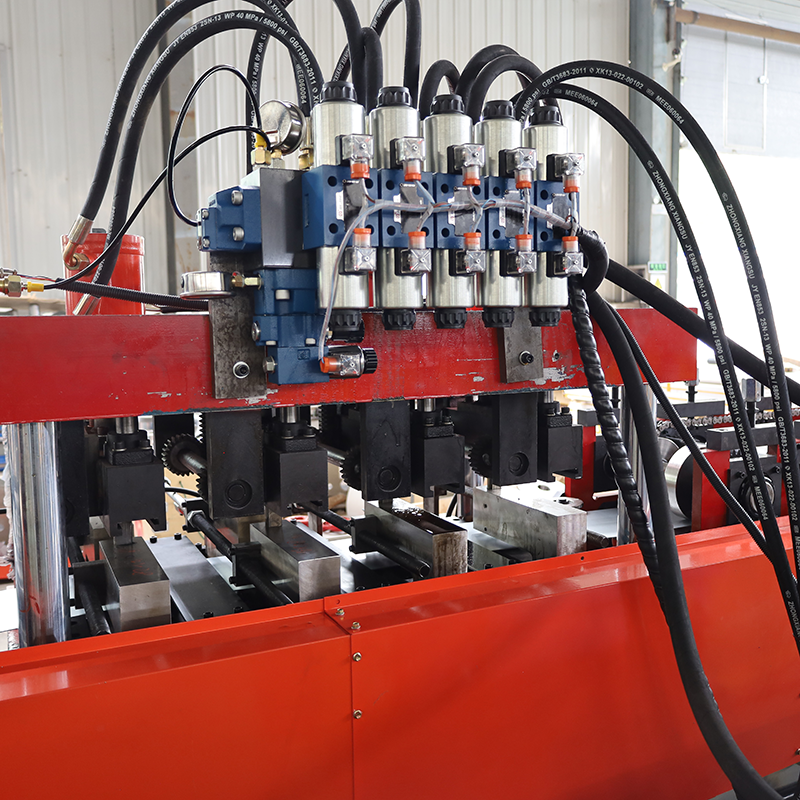

Pump Station Motor |

4Kw |

| Thickness of the plate | 0.3-1.2mm |

| Productivity | 0-20m/min |

| Material of the cutting blade | Cr12,Quenched treatment 58ºC-60ºC |

| Diameter of the roller | Φ70mm |

| Weight | About 4500kgs |

|

Main structure of the machine |

350H beams |

| Processing precision | Within 1.0mm |

|

Side panel of machine |

16mm |

| Chain Wheel and Cycle Chain | 1.2 Inch |

| Voltage | 380V 50Hz 3phases or as customer's need |

| Control system | PLC control (Delta) |

| Frequency system | Delta |

|

Drive mode |

Motor driver |

| Touch screen | Delta |

| Rolling materials | 45# forging steel with chromium plate |

| Length Tolerance | ±2mm |

Free accessories

COMPANY INTRODUCTION

Zhongke Roll Forming Machine Factory has over 20 years of experience in manufacturing roll-forming machines, with a skilled team of 100 workers and a 20,000 square meters workshop. it is known for its high-quality machines, personalized services and fiexdble options, including custom design and manufacturing At Zhongke Roll Forming Machine Factory, they are committed to providing personalized and flexible services to meet the specific needs of so many clients, they offer custom design and manufacturing services, Their product range includes Light Gauge Building Steel Frame Roll Forming Machines, Glazed Tile Forming Machines, Roof Panel and Wall Panel Molding Machines, C/Z Steel Machines, and more. zhongke is passionate about their work and committed to exceeding clients' expectations. Hope you for considering Zhongke Roll Forming Machine Factory!

PRODUCT LINE

OUR CUSTOMERS

Our products are sold to many countries and regions all over theworld, and we have established long-term cooperative relations with clients!

PACKAGING & LOGISTICS

FAQ

Q1: How to play order?

A1:Inquiry---Confirm the profile drawings and price ---Confirm Thepl---Arrange the deposit or L/C---Then ok

Q2: How to visit our company?

A2: Fly to Beijing airport: By high speed train from Beijing Nan to Cangzhou Xi(1 hour),then we will pick you up.

Fly to Shanghai Hongqiao airport:By high speed train from Shanghai Hongqiao to Cangzhou Xi(4 hour),then we will pick you up.

Q3: Are you manufacturer or trading company?

A3: We are manufacturer and trading company.Had very greatful experience.

Q4: Do you provide installing and training overseas?

A4: Overseas machine install and worker training services are optional.

Q5: How is your after sales support?

A5: We provide technical support on line as well as overseas services by skillful technicians.

Q6: How does your factory do regarding quality control?

A6: There is no tolerance regarding quality control. Quality control complies with ISO9001. Every machine has to past testing running before it's packed for shipment.

Q7: How can I trust you that machines pasted testing running before shipping?

A7: (1) We record the testing video for your reference. Or,

(2) We welcome your visit us and test machine by yourself in our factory

Q8: Do you sell only standard machines?

A8: No. Most machines are customized.

Q9: Will you deliver the right goods as ordered? How can I trust you?

A9: Yes, we will. We are Gold supplier of Made-in-China with SGS assessment (Audit report can be provided).