In manufacturing, efficiency and quality are critical. This makes the use of advanced machinery and equipment a necessity for businesses to stay ahead of the competition. One of the pieces of equipment that has revolutionized the industry is the glazed roll forming machine.

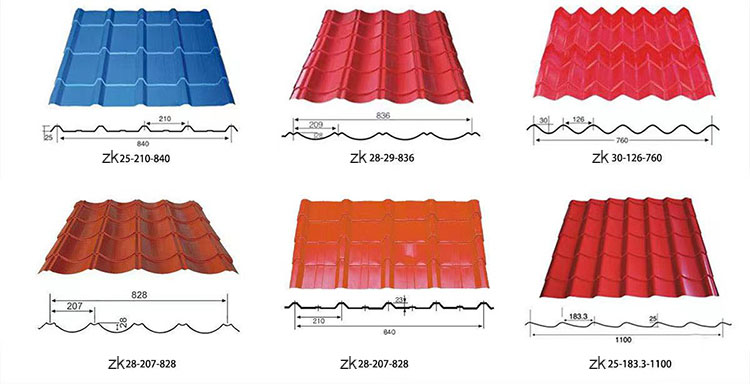

Glazed roll forming machines are high-precision equipment used to form metal sheets into specific shapes and profiles. They are a key component in the production of a variety of products such as roofing sheets, wall cladding and other building materials. The process involves feeding a strip of metal through a series of rollers that gradually shape the material into the desired shape. Adding a glaze gives the final product a sleek and polished look, making it very popular in the building and construction industry

Using a glaze roll forming machine offers many advantages to manufacturers. First, these machines are able to produce consistent and precise shapes, thereby increasing product quality levels. This is critical to meeting the strict standards and requirements of the construction industry. In addition, the automation and speed of glazed roll forming machines can increase productivity and reduce production time. This can save costs and improve the profitability of the business.

Additionally, the versatility of glazed roll forming machines makes them suitable for a wide range of applications. With the ability to produce different profiles and finishes, manufacturers can meet different customer needs and design specifications. As a result, businesses can expand their product range and attract a larger customer base. This flexibility and customization are key factors in staying competitive in the market.

In recent years, technological advancements have further enhanced the capabilities of glazed roll forming machines. The integration of computer control and advanced software enables greater precision and customization of the molding process. This opens up new possibilities for product design and innovation, giving manufacturers a clear advantage in the market. Furthermore, the use of energy-saving components and sustainable materials in modern glazed roll forming machines is in line with the manufacturing industry's growing focus on environmental responsibility.

As the demand for high-quality, aesthetically pleasing building materials continues to rise, the importance of glazed roll forming machines in modern manufacturing cannot be overstated. Their ability to efficiently produce complex profiles and finishes makes them an indispensable asset for businesses aiming to meet the ever-changing needs of the construction industry.

In summary, glass roll forming machines have become an integral part of the manufacturing sector, especially in the production of building materials. Their precision, speed and versatility make them a valuable investment for businesses looking to increase their production capabilities. As technology continues to evolve, we can expect to see further innovations in glazed roll forming machines, allowing for greater efficiency and customization in the manufacturing process.

Post time: Jan-11-2024