Corrugated roll forming machines are an essential piece of equipment in the manufacturing industry, particularly in the production of corrugated metal sheets used in roofing, cladding, and other construction applications. These machines play a crucial role in shaping flat metal sheets into the distinct corrugated profile, providing strength, durability, and aesthetic appeal to the end product. Let's explore the significance and functionality of corrugated roll forming machines in detail.

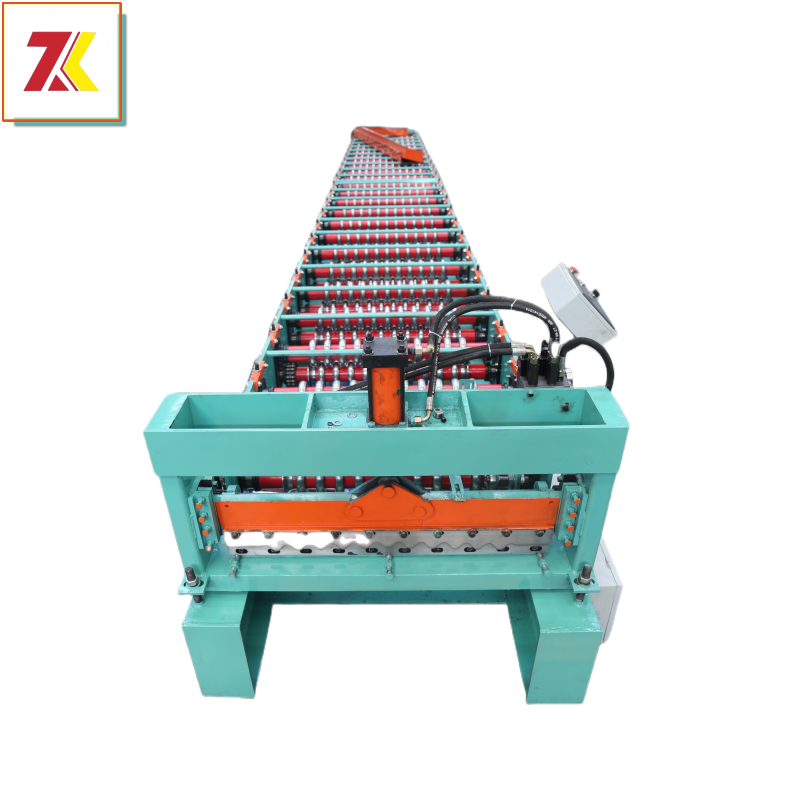

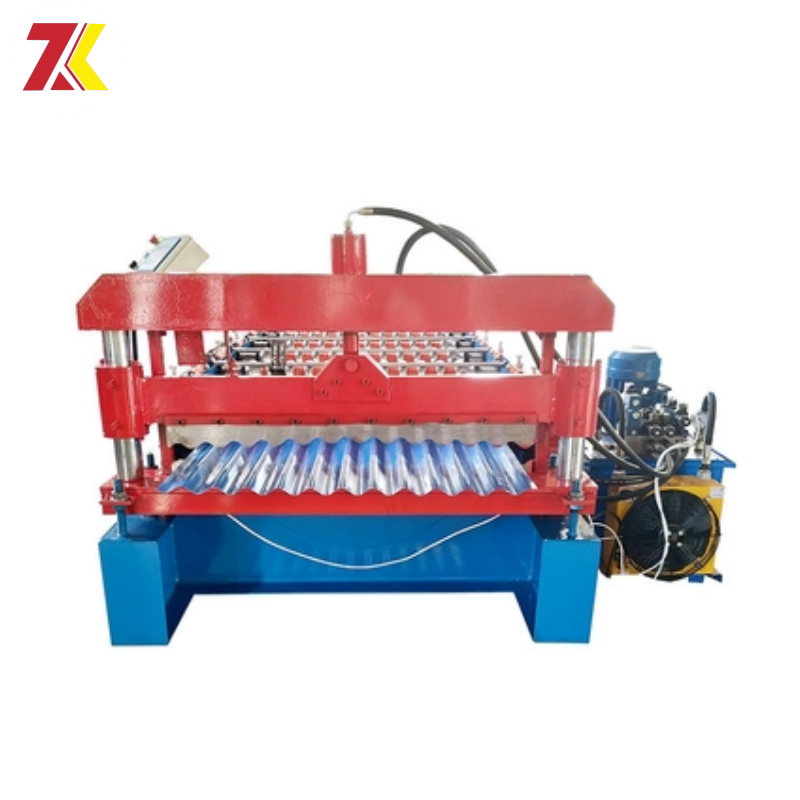

The corrugated roll forming machine is a specialized apparatus designed to transform flat metal coils or sheets into corrugated profiles through a series of precise and controlled steps. This process involves feeding the metal material through a set of rollers that gradually shape and form it into the desired corrugated pattern. The machine's intricate design and engineering enable it to produce uniform and high-quality corrugated sheets with consistent dimensions, ensuring that the end product meets the required specifications.

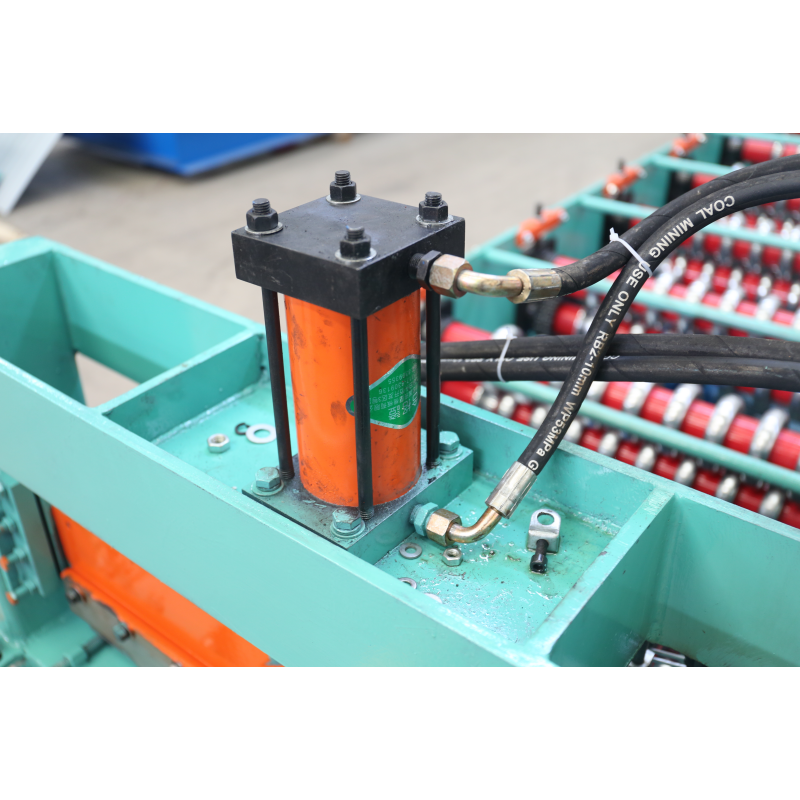

One of the key components of the corrugated roll forming machine is the set of corrugating rollers, which are carefully crafted to create the distinctive waves or ridges on the metal sheet. These rollers are precisely aligned and calibrated to ensure the accurate formation of the corrugated profile, and they can be customized to produce various types of corrugation patterns to suit different applications. Additionally, the machine incorporates cutting and finishing mechanisms to trim the corrugated sheets to the desired length and shape the edges for a seamless fit during installation.

The versatility of corrugated roll forming machines allows for the manufacturing of a wide range of corrugated products, including roofing panels, wall cladding, decking, and fencing materials. These machines are capable of processing different types of metals, such as galvanized steel, aluminum, and stainless steel, offering manufacturers the flexibility to produce diverse corrugated products to meet market demands.

In addition to their production capabilities, corrugated roll forming machines are designed for efficiency and productivity. With the integration of advanced controls and automation systems, these machines can operate at high speeds while maintaining precision and accuracy throughout the forming process. This not only enhances the overall production output but also ensures that the corrugated sheets meet stringent quality standards.

Furthermore, corrugated roll forming machines are engineered for reliability and durability, allowing for continuous operation in demanding manufacturing environments. Proper maintenance and regular servicing are essential to uphold the machine's performance and extend its operational lifespan. Additionally, manufacturers can optimize the machine settings and tooling configurations to adapt to different material thicknesses and profiles, further enhancing its versatility and efficiency.

In conclusion, corrugated roll forming machines are indispensable assets in the production of corrugated metal products, offering a blend of precision, efficiency, and versatility. With their ability to consistently produce high-quality corrugated sheets for various applications, these machines are instrumental in driving the construction and manufacturing industries forward, meeting the evolving needs of infrastructure and building projects. As technology and innovation continue to advance, corrugated roll forming machines will remain at the forefront of shaping the future of construction materials.

Post time: Dec-26-2023