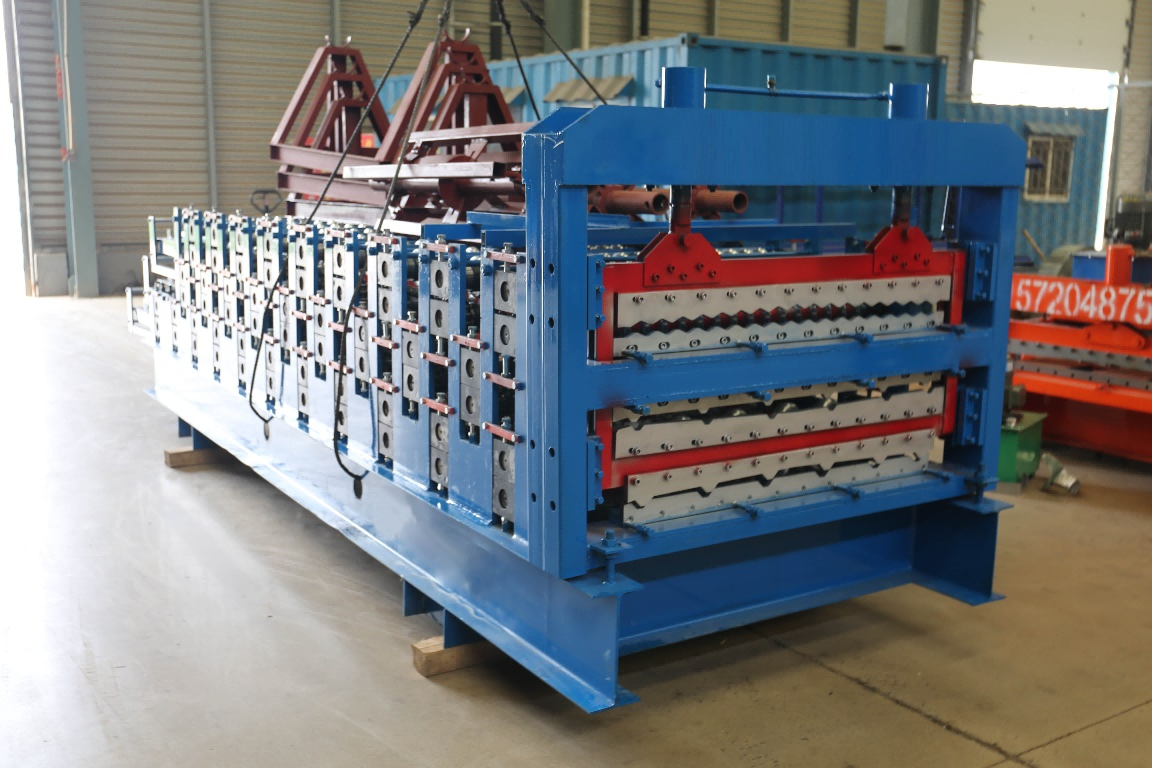

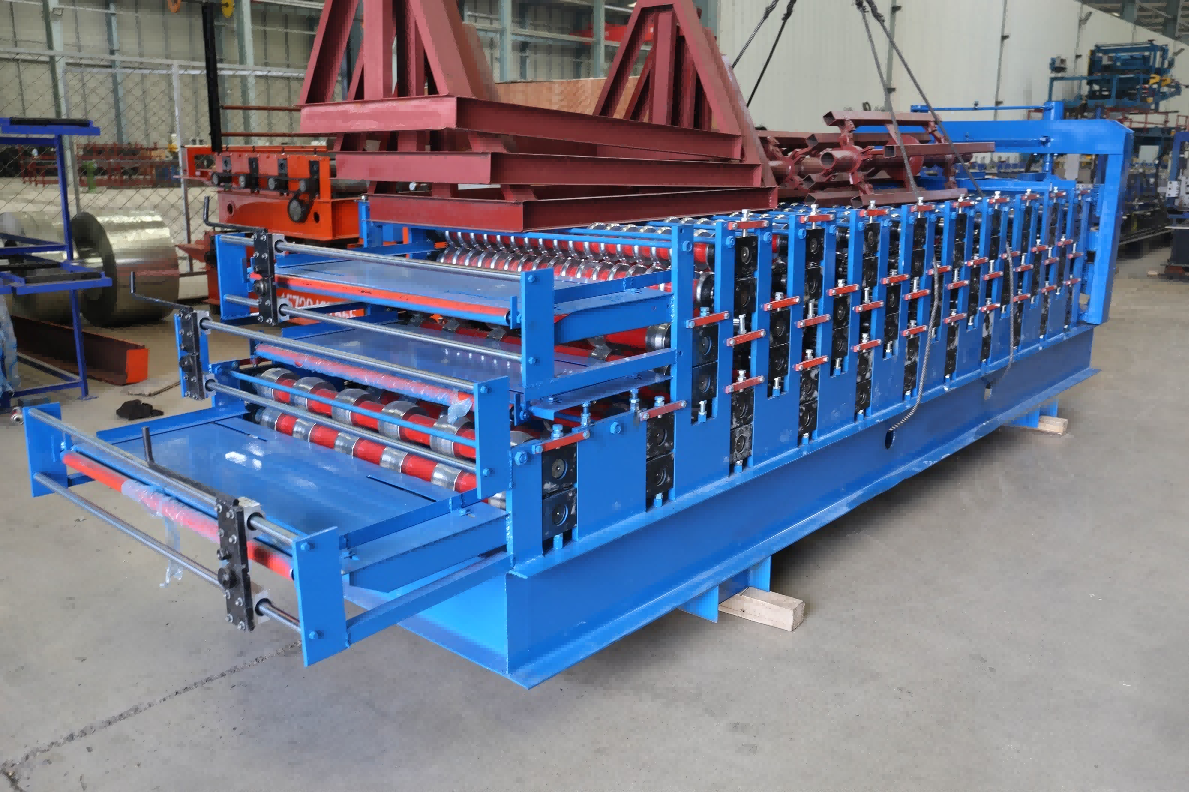

Innovative Triple-Layers Roofing Sheet Forming Equipment

Product descriptions from the supplier

Overview

PRODUCT DESCRIPTION OF Zhongke 3-layers roll forming machine

The Zhongke 3-layers roll forming machine

The 3-layers Roll Forming Machine is a specialized piece of equipment designed for efficiently manufacturing metal products with precise seam formations. It utilizes a series of precision-engineered rollers arranged in a stand-mounted configuration, allowing for continuous and automated shaping of metal sheets into desired profiles. The machine feeds metal coils or sheets through its rollers, progressively bending and folding the material to create strong, seamless joints or intricate seam patterns.This process ensures consistent quality and dimensional accuracy, ideal for producing components such as roofing panels, siding,gutters, and other architectural metalwork. The stand seaming mechanism provides added strength to the finished product by tightly locking the edges together, enhancing its durability and esistance to weathering.Operators can adjust the machine settings to accommodate different material thicknesses and seam specifications, ensuring versatility across various production needs. Additionally, the automated nature of the roll forming process significantly reduces labor costs and increases production speed, making it an essential tool for modern metal fabrication facilities.

PRODUCT DESCRIPTION OF Zhongke 3-layers roll forming machine

Noted: There are two types of roll forming machines: standard type and customized type. If you need to customize, please send us the design drawing,feeding width, thickness and raw materials, so that we can customize according to your requirements, which is very important for us!!!

We are online 24 hours a day, please feel free to inquire for more discounts! Entering the store for inquiry and placing an order will get an additional complimentary gift!

|

|

hree Layer Roof Slate Metal Tile Making Machine Trapezoidal Corrugated Ibr Roof Sheet Roll Forming

Machine Prices

Customized shape profile panel metal roll forming roof sheet making machine,it is our company most popular products in building materials machine. For roof sheet, it include many type according to its different shape, popular type include corrugated tile roll forming machine, trapezoidal tile roll forming machine,glazed tile roll forming machine, ridge cap roll forming machine and other type profile panel roll forming machine.

When you choose roof sheet making machine, you had better learn popular shape in local,also raw material is an important considering data, if do not have good supplier in local, we can assist you purchase it in China together. we are professional factory and in this area for many years, any requires please contact us at any time!

| No | Item | Data |

|

1 |

Raw material width |

1000-1200 mm |

|

2 |

Sheet effective width |

750-1000 mm |

|

3 |

Raw material |

Color steel sheet or galvanized steel sheet |

|

4 |

Material thickness |

0.3-0.8 mm or customized |

|

5 |

Forming roller material |

45# steel plated with chrome |

|

6 |

Shaft diameter |

70 mm |

|

7 |

Forming roll station |

8-16 steps |

|

8 |

Main motor power |

3 KW 4 KW 5.5 KW(according to type) |

|

9 |

Hydraulic power |

4 KW (according to type) |

|

10 |

Control system |

PLC control |

MACHINE DETAILS OF Zhongke 3-layers roll forming machine

PRODUCTS APPLICATIONS INTRODUCTION OF Zhongke 3-layers roll forming machine

The finished product of this roof panel forming machine can be applied to the roofs and walls of metal building structures. It is durable and wear-resistant, has a long service life, low production cost, fast speed, and high cost-effectiveness.

CERTIFICATES OF Zhongke 3-layers roll forming machine

COMPANY INTRODUCTION OF Zhongke 3-layers roll forming machine

Zhongke Roll Forming Machine Factorydriven by science and technology innovation, focus on high-quality tile pressing equipment research and development and production. We are committed to providing intelligent, efficient and durable machine production solutions that meet the diverse needs of the construction industry and ensure that our products are robust and durable to help the construction industry thrive

OUR CUSTOMERS OF Zhongke 3-layers roll forming machine

PACKAGING & LOGISTICS OF Zhongke 3-layers roll forming machine

FAQ

1. Can the machine only produce one size or shape? Not quite. We have standard configuration and customized machines. For machine customization, you need to contact us to provide relevant information.

2. Do you have after-sales support? Yes, we are happy to provide suggestions. If necessary, we also have skilled technicians to guide the maintenance of the machine via video.

3. Can you be responsible for transportation? Yes, please tell us the port of destination or address. We have rich experience in transportation and will choose the most economical and reliable transportation company for you.

4. Why is your price higher than others? Because we insist that every factory should put quality first. We spend time and money to develop how to make machines more automatic, accurate and high-quality. We can ensure that our machines can be used for more than 20 years without any problems.

5. Do you provide customized services? Of course, we can design the equipment according to the drawing parameter data provided by you. We are a professional machinery manufacturer.