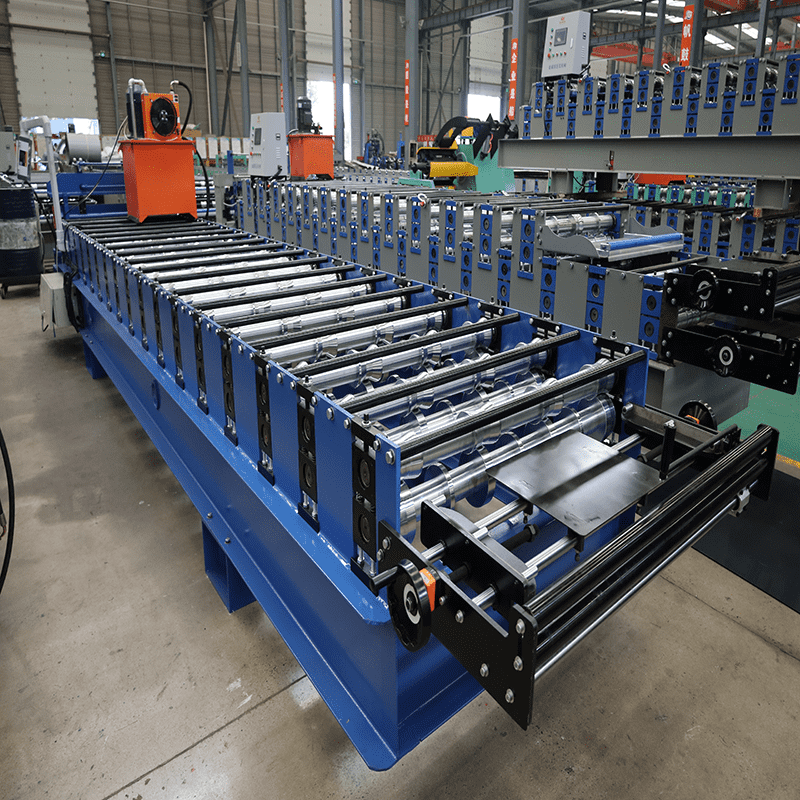

Glazed Tile Roll Forming Machine

Product descriptions from the supplier Overview

PRODUCT DESCRIPTION OF Zhongke Glazed Tile Roll Forming Machine

The Zhongke Glazed Tile roll forming machine

1. The blade only has cr12mov, which is of good quality, strong and wear-resistant.

2. The chain and middle plate are widened and thickened, and the production performance is more stable.

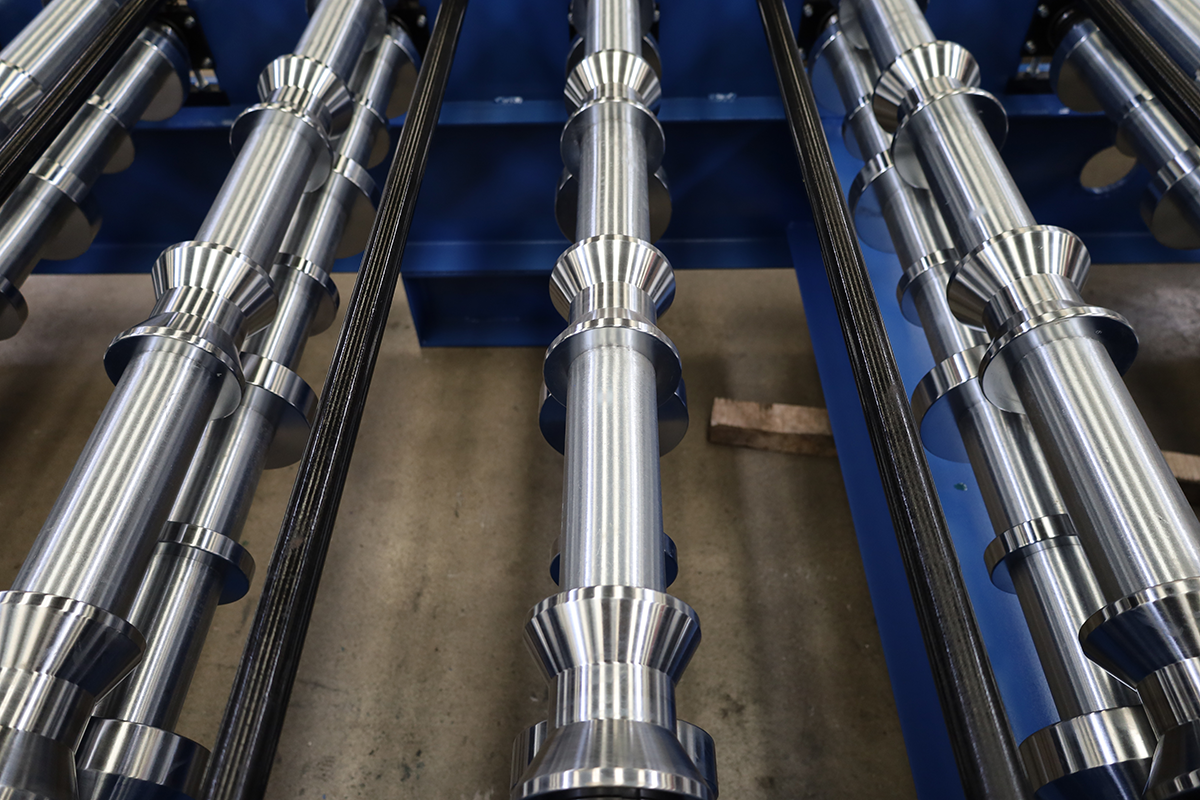

3. The wheel adopts overtime electroplating, and the coating reaches +0.05 mm.

4. The whole machine adopts shot blasting machine to remove rust, and spray both sides of the primer and the two sides of the topcoat to strengthen the adhesion of the machine to the paint, not only beautiful in appearance, but also not easy to wear.

PURLIN SPECIFICATIONS OF Zhongke Glazed Tile Roll Forming Machine

| Strip width | 1200mm. |

| Strip thickness | 0.3mm-0.8mm. |

| Steel coil inner diameter | φ430~520mm. |

| Steel coil outer diameter | ≤φ1000mm. |

| Steel coil weight | ≤3.5 tons. |

| Steel coil material | PPGI |

MACHINE DETAILS OF Zhongke Double Layer Roll Forming Machine

COMPANY INTRODUCTION OF Zhongke Double Layer Roll Forming Machine

Zhongke Roll Forming Machine Factorydriven by science and technology innovation, focus on high-quality tile pressing equipment research and development and production. We are committed to providing intelligent, efficient and durable machine production solutions that meet the diverse needs of the construction industry and ensure that our products are robust and durable to help the construction industry thrive

OUR CUSTOMERS OF Zhongke Double Layer Roll Forming Machine

PACKAGING & LOGISTICS OF Zhongke Double Layer Roll Forming Machine

FAQ

Q1.How to get a quotation?

A1) Give me the dimension drawing and thickness, it is very important.

A2) If you have requirements for production speed, power, voltage and brand, please explain in advance.

A3) If you don't have your own outline drawing, we can recommend some models according to your local market standard.

Q2. What's your payment terms and delivery time?

A1: 30% as the deposit by T/T in advance, 70% as the balance payment by T/T after your inspect the machine well and before delivery. Of course your payment terms like L/C are acceptable.

After we get down payment, we will arrange production. About 30-45 days for delivery.

Q3. Do you sell only standard machines?

A3: No, most of our machines are built according to customers specifications, using top brand components.

Q4. What will you do if the machine is broken?

A4: We provide 24 months free warranty and free technical support for the whole life of any machine.If the broken parts can't repair, we can send the new parts replace the broken parts freely, but you need pay the express cost by yourself. If it is beyond the warranty period, we can negotiate to solve the problem, and we supply the technical support for the whole life of the equipment.

Q5. Can you be responsible for transport?

A5: Yes, please tell me the destination port or address. we have rich experience in transporting.