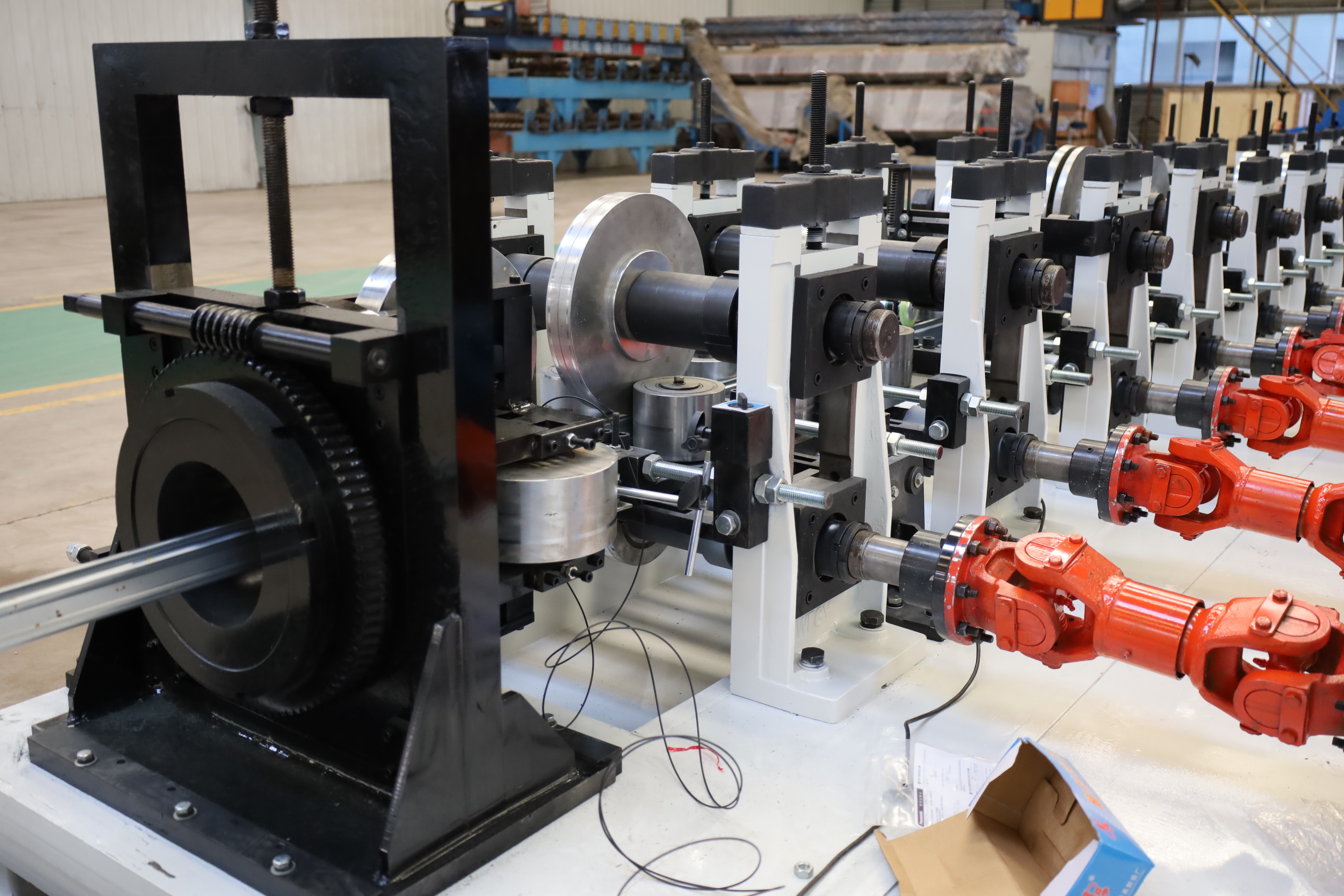

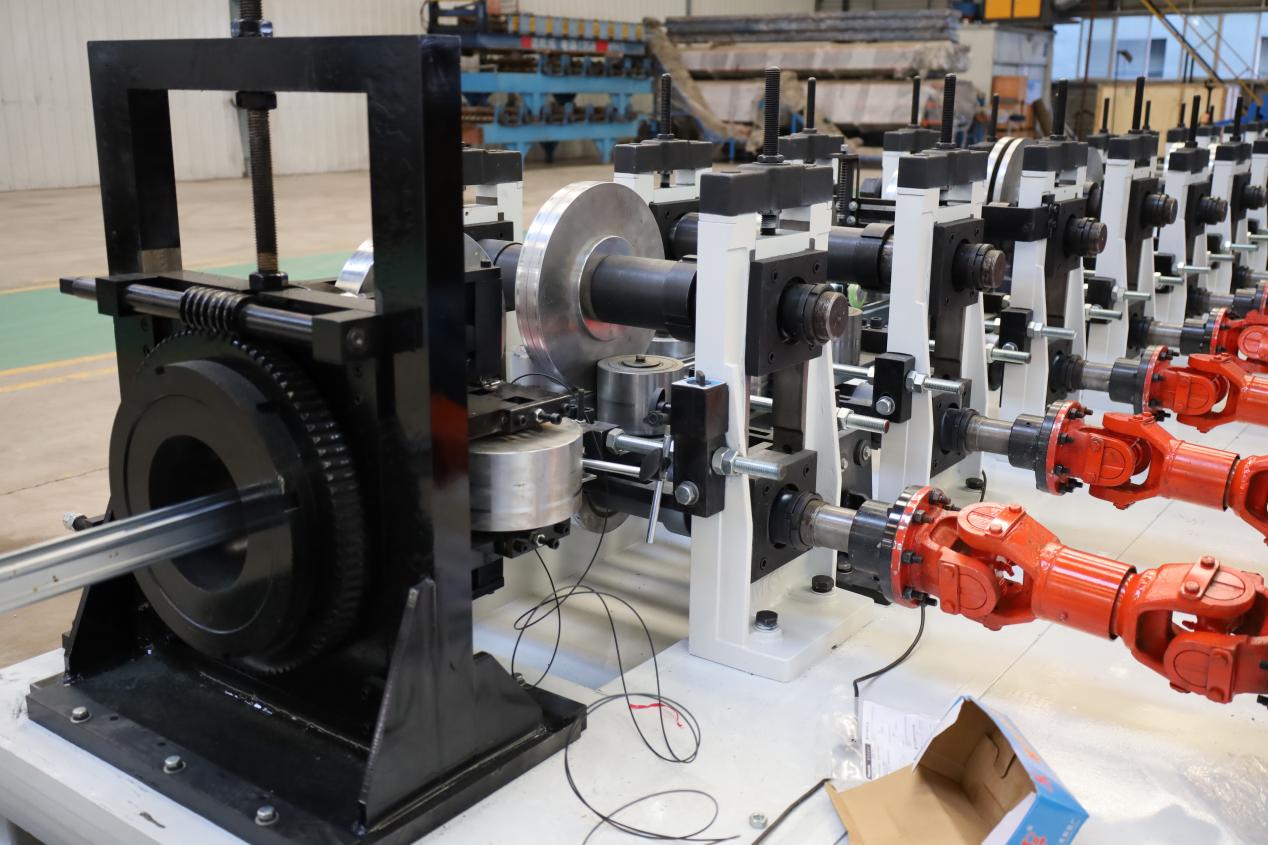

Fully Automatic Solar Photovoltaic Roll Forming Machine

The automatic production line of photovoltaic solar support can produce various cross-sectional specifications and models of support profiles by switching. The change of version is quick and convenient, and one person can operate the whole line. PLC centrally controls the uncoiling, leveling and feeding, fixed-length punching, roll forming, follow-up cutting, and discharging of the entire line. It can set multiple sets of workpiece data tasks at one time, automatic production, and remote control.

|

Technical parameters |

|

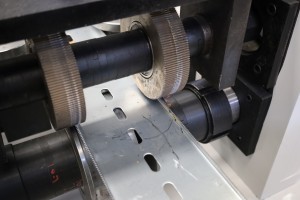

| Suitable Plate Material | thickness 1.5-2.5mm, Galvanized steel or blank steel |

| Working Speed | 8-9 meters / min |

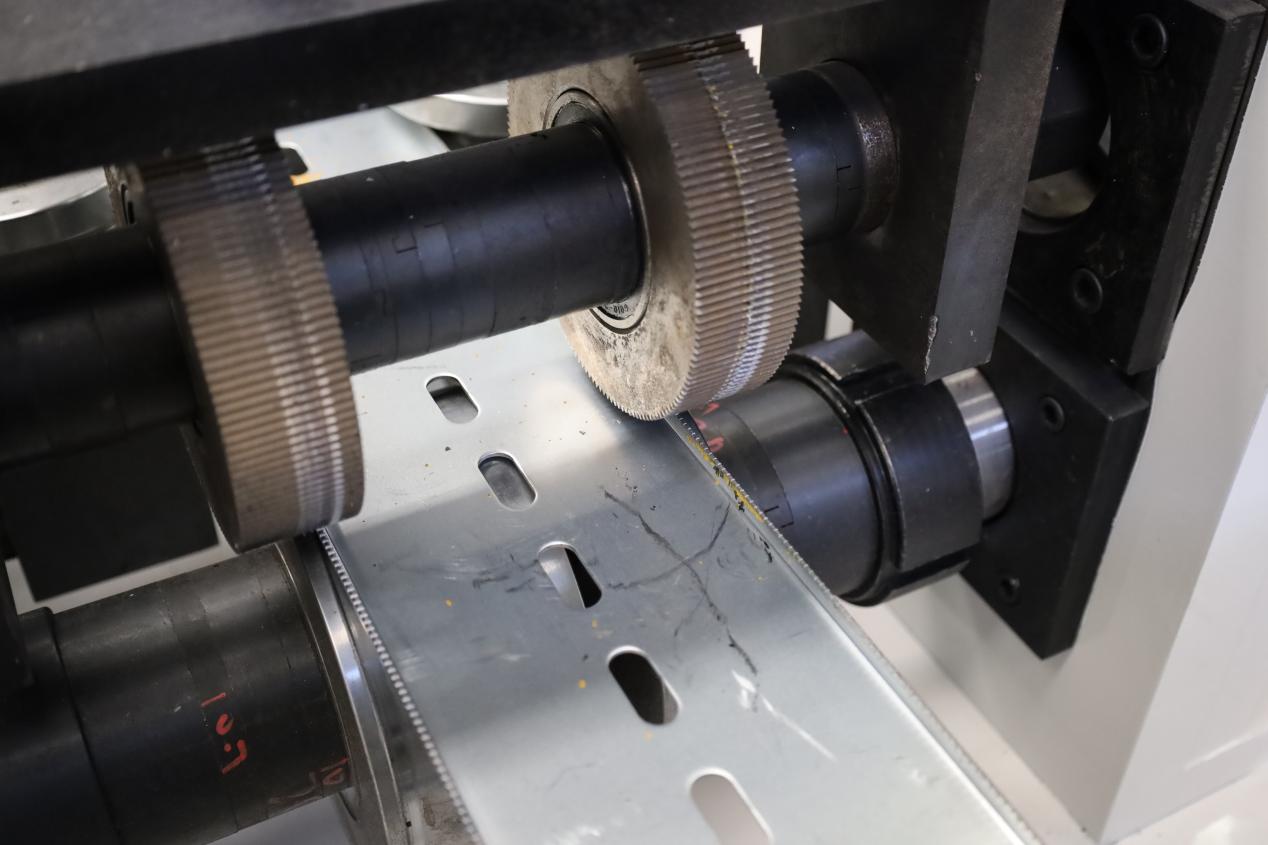

| Forming Steps | about 19 stations |

| Trademark | ZHONGKE MACHINERY |

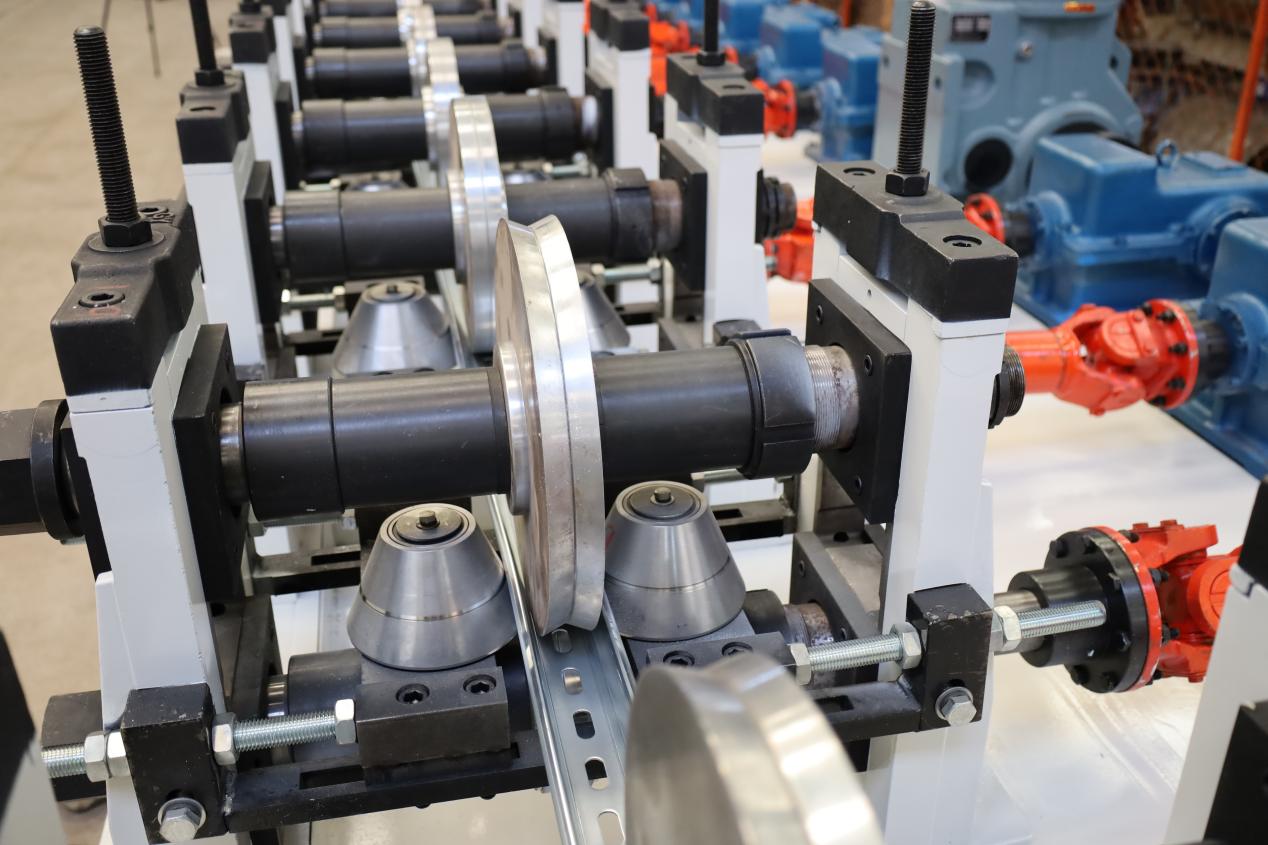

| Material of Roller | Gcr15, Quench HRC58-62 Plated Chrome |

| Material Type | PPGL,PPGI |

| Material of Shaft | 45# Advanced Steel (Diameter: 76mm), thermal refining |

| Driven system | Gearbox driven |

| Main Power with reducer | 18.5KW WH Chinese Famous |

| Motor power of hydraulic station | 5.5KW |

| Voltage | 380V 50Hz 3phases |

| Material of cutting blade | Cr12Mov , quenching process |