Fully automatic size adjustable standing seam roof panel roll forming machine

Product descriptions from the supplier Overview

PRODUCT DESCRIPTION OF Zhongke standing seam roll forming machine

The Zhongke standing seam roll forming machine

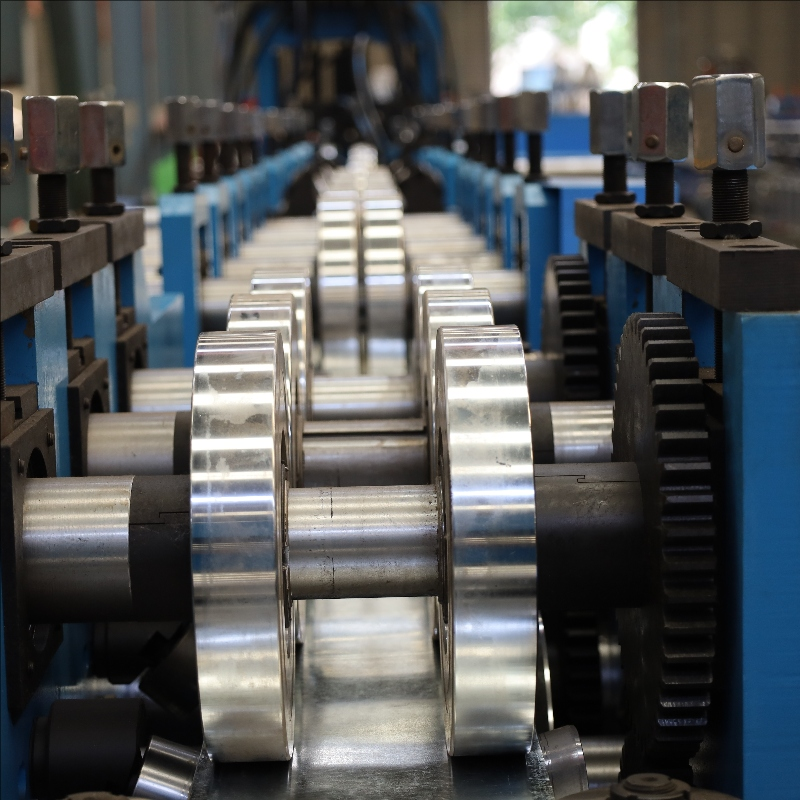

The Stand Seaming Roll Forming Machine is a specialized piece of equipment designed for efficiently manufacturing metal products with precise seam formations. It utilizes a series of precision-engineered rollers arranged in a stand-mounted configuration, allowing for continuous and automated shaping of metal sheets into desired profiles. The machine feeds metal coils or sheets through its rollers, progressively bending and folding the material to create strong, seamless joints or intricate seam patterns.This process ensures consistent quality and dimensional accuracy, ideal for producing components such as roofing panels, siding,gutters, and other architectural metalwork. The stand seaming mechanism provides added strength to the finished product by tightly locking the edges together, enhancing its durability and esistance to weathering.Operators can adjust the machine settings to accommodate different material thicknesses and seam specifications, ensuring versatility across various production needs. Additionally, the automated nature of the roll forming process significantly reduces labor costs and increases production speed, making it an essential tool for modern metal fabrication facilities.

PURLIN SPECIFICATIONS OF Zhongke standing seam roll forming machine

The Zhongke of Container Panel Forming Machine Cold Roll Forming Machine is a high-efficiency, fully automated solution designed for the production of high-quality ridge tiles. With integrated manufacturing and trading capabilities, this machine offers precision roll forming, rapid tool changes, and a user-friendly digital control panel. Constructed with durable materials and featuring a compact design, it ensures stable and efficient operation. The machine is capable of processing a variety of materials, providing consistent and precise results. Ideal for construction projects, it streamlines the production process and maximizes productivity.

| Portable full automatic SSR Standing seam metal roof sheet roll forming machine for sale price | ||

| 1.Formed Material | PPGI,GI,AI | Thickness:0.4-0.8mm Width:as the profile drawing |

| 2.Decoiler | Hydraulic automatic decoiler | Manual decoiler(will give you as free) |

| 3.Main body

|

Roller station | 12 rows (Design as the profile drawing) |

| Diameter of shaft | 70mm solid shaft | |

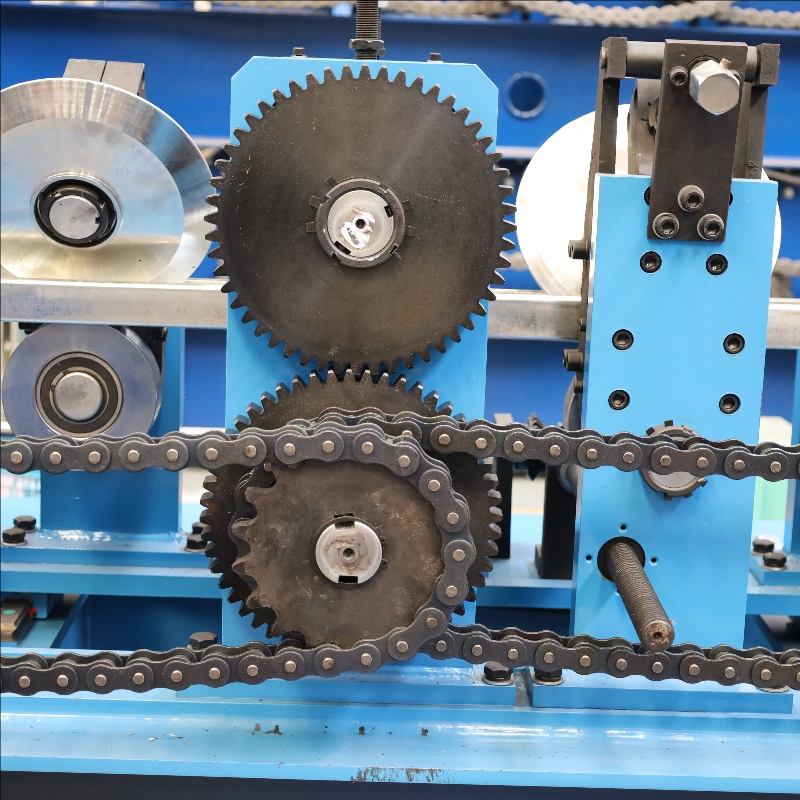

| Material of rollers | 45# steel, hard chrome plated on the surface | |

| Machine body frame | 350 H steel | |

| Drive | Chain transmission | |

| Dimension(L*W*H) | 5500*1600*1600(customize) | |

| Weight | 3.5T | |

| 4.Cutter | Automatic | cr12mov material, no scratches, no deformation |

| 5.Power

|

Motor Power | 5.5KW |

| Hydraulic system power | 4KW | |

| 6.Voltage | 380V 50Hz 3Phase | As your requirement |

| 7.Control system

|

Electric Box | Customized(famous brand) |

| Language | English(Support multiple languages) | |

| PLC | Automatic production of the whole machine. Can set batch, length, quantity, etc. | |

| 18.Forming Speed | 15-20m/min | The speed is adjustable as customer's request |

MACHINE DETAILS OF Zhongke standing seam roll forming machine

COMPANY INTRODUCTION OF Zhongke standing seam roll forming machine

Zhongke Roll Forming Machine Factorydriven by science and technology innovation, focus on high-quality tile pressing equipment research and development and production. We are committed to providing intelligent, efficient and durable machine production solutions that meet the diverse needs of the construction industry and ensure that our products are robust and durable to help the construction industry

PACKAGING & LOGISTICS OF Zhongke standing seam roll forming machine

PACKAGING & LOGISTICS OF Zhongke Double Layer Roll Forming Machine

FAQ

Q1.How to get a quotation?

A1) Give me the dimension drawing and thickness, it is very important.

A2) If you have requirements for production speed, power, voltage and brand, please explain in advance.

A3) If you don't have your own outline drawing, we can recommend some models according to your local market standard.

Q2. What's your payment terms and delivery time?

A1: 30% as the deposit by T/T in advance, 70% as the balance payment by T/T after your inspect the machine well and before delivery. Of course your payment terms like L/C are acceptable.

After we get down payment, we will arrange production. About 30-45 days for delivery.

Q3. Do you sell only standard machines?

A3: No, most of our machines are built according to customers specifications, using top brand components.

Q4. What will you do if the machine is broken?

A4: We provide 24 months free warranty and free technical support for the whole life of any machine.If the broken parts can't repair, we can send the new parts replace the broken parts freely, but you need pay the express cost by yourself. If it is beyond the warranty period, we can negotiate to solve the problem, and we supply the technical support for the whole life of the equipment.

Q5. Can you be responsible for transport?

A5: Yes, please tell me the destination port or address. we have rich experience in transporting.