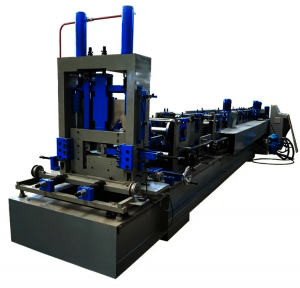

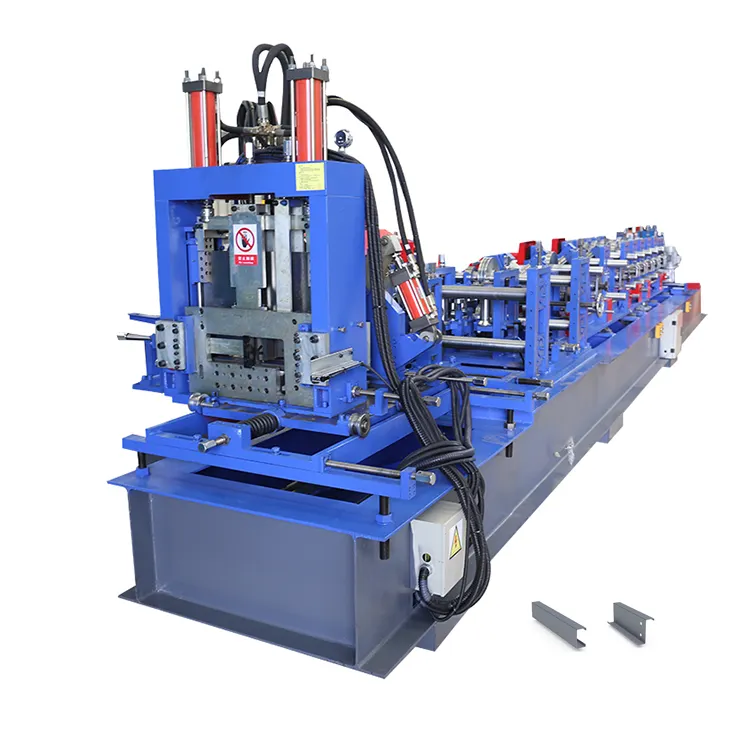

ZKRFM C Z Purlin Machine CZ Profile Roll Forming Machine CZ Roll Forming Machine

PRODUCT DESCRIPTION

| Formed Material | PPGI,GI,AI | Thickness:0.3-0.8 mm |

| Decoiler | Hydraulic decoiler | Manual decoiler(will give you as free) |

| Main body | Roller station | 9-11rows(As your requirement) |

| Diameter of shaft | 70mm solid shaft | |

| Material of rollers | 45# steel, hard chrome plated on the surface | |

| Machine body frame | 350H steel | |

| Drive | Double Chain transmission | |

| Dimension(L*W*H) | About 6.5X1.6X1.7M | |

| Weight | About 6ton | |

| Cutter | Automatic | cr12mov material, no scratches, no deformation |

| Power | Main Power | 0.75*3KW or As your requirement |

| Voltage | 380V 50Hz 3Phase | As your requirement |

| Control system | Electric Box | Customized(famous brand) |

| Language | English(Support multiple languages) | |

| PLC | Automatic production of the whole machine. Can set batch, length, quantity, etc. | |

| Forming Speed | 25m/min | The speed depends on the shape of the tile and the thickness of the material. |

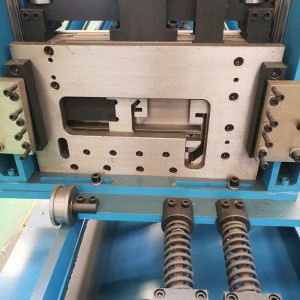

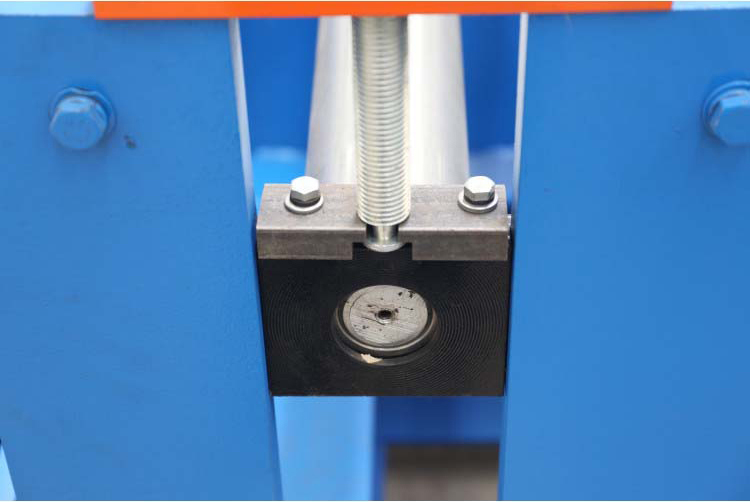

High strength top screws

High-strength top screws are crucial components in a roll forming machine, providing unparalleled stability and precision, ensuring flawless metal sheet shaping for our customers' manufacturing processes.

Cylinder protection

Cylinder protection is a crucial component of our roll forming machine, ensuring the durability and longevity of the equipment. It safeguards the precision-engineered cylinders, enhancing performance and minimizing maintenance costs.

Travel switch

The Travel Switch is an essential component of our roll forming machine, ensuring precise and automated positioning of materials. It enhances efficiency and accuracy in the production process, making it a valuable tool for our customers.

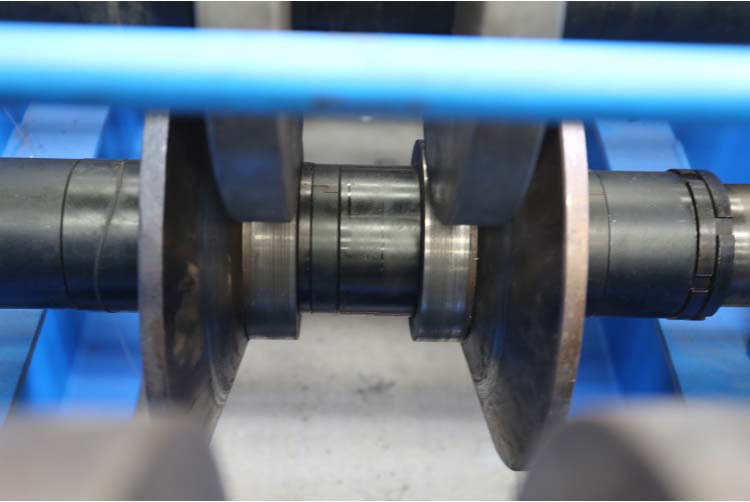

Chrome treated shaft and wheel

The Chrome-treated shaft and wheel for our roll forming machine ensure exceptional durability and smooth operation. The chrome coating enhances resistance to wear and corrosion, prolonging the machine's lifespan and maintaining consistent performance.

COMPANY INTRODUCTION

PRODUCT LINE

OUR CUSTOMERS

PACKAGING & LOGISTICS