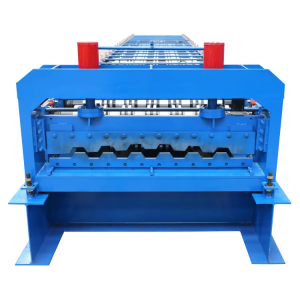

Customizable Double Layer Roof Panel Roll Forming Machine New Motor Bearing Pump Gear Core Components Tile Making Machinery Tile

Product descriptions from the supplier Overview

PRODUCT DESCRIPTION OF Double layers roll forming machine

The double layer roll forming machine is a cutting-edge production system that revolutionizes the manufacturing of dual-layer metal structures. It seamlessly integrates two separate metal sheets into a single, robust product through precise and continuous rolling processes. This innovative machine excels in crafting intricate and custom designs for a variety of applications, from automotive components to construction materials. Its advanced technology optimizes material usage, reducing waste and costs. The double layer roll forming machine is a flexible solution that adapts to different production needs, offering scalability and versatility to manufacturers looking to streamline their operations and elevate their product offerings..

PURLIN SPECIFICATIONS OF Double layers roll forming machine

| item | value |

| Applicable Industries | Building Material Shops, Manufacturing Plant, Machinery Repair Shops, Construction works |

| Showroom Location | Egypt |

| Condition | New |

| Type | Tile Forming Machine |

| Tile Type | Steel |

| Use | ROOF |

| Production Capacity | 0-8m/min |

| Place of Origin | China |

| - | Hebei |

| Brand Name | zhongke |

| Voltage | 380V |

| Dimension(L*W*H) | 7000*1500*1500mm |

| Weight | 7000kg |

| Warranty | 2 years |

| Key Selling Points | Easy to Operate |

| Rolling thinckness | 0.3-0.8mm |

| Feeding width | Other |

| Machinery Test Report | Provided |

| Video outgoing-inspection | Provided |

| Marketing Type | New Product 2023 |

| Warranty of core components | 1.5 years |

| Core Components | Motor, Bearing, Gear, Pump, PLC |

MACHINE DETAILS OF Jch Roof Panel Roll Forming Machine

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

COMPANY INTRODUCTION OF Roof Sheet Roll Forming Machine

Established for over two decades, Zhongke Roll Forming Machine Factory boasts an impressive track record in manufacturing roll-forming machines. With a dedicated workforce of 100 skilled craftsmen and a sprawling 20,000 square meter workshop, we are renowned for delivering exceptional quality machines tailored to meet individual requirements.

At Zhongke, we pride ourselves on offering personalized and adaptable services that cater to the unique needs of our diverse clientele. Our commitment to customization extends to our design and manufacturing processes, ensuring that every machine is tailored to perfection.

Our comprehensive product portfolio encompasses a wide array of roll-forming solutions, including Light Gauge Building Steel Frame Roll Forming Machines, Glazed Tile Forming Machines, Roof Panel and Wall Panel Molding Machines, C/Z Steel Machines, and more. Each machine is a testament to our unwavering dedication to excellence and innovation.

At Zhongke Roll Forming Machine Factory, we are driven by a passion for our craft and a relentless pursuit of surpassing client expectations. We invite you to consider Zhongke as your trusted partner for all your roll-forming machine needs.

Established for over two decades, Zhongke Roll Forming Machine Factory boasts an impressive track record in manufacturing roll-forming machines. With a dedicated workforce of 100 skilled craftsmen and a sprawling 20,000 square meter workshop, we are renowned for delivering exceptional quality machines tailored to meet individual requirements.

At Zhongke, we pride ourselves on offering personalized and adaptable services that cater to the unique needs of our diverse clientele. Our commitment to customization extends to our design and manufacturing processes, ensuring that every machine is tailored to perfection.

Our comprehensive product portfolio encompasses a wide array of roll-forming solutions, including Light Gauge Building Steel Frame Roll Forming Machines, Glazed Tile Forming Machines, Roof Panel and Wall Panel Molding Machines, C/Z Steel Machines, and more. Each machine is a testament to our unwavering dedication to excellence and innovation.

At Zhongke Roll Forming Machine Factory, we are driven by a passion for our craft and a relentless pursuit of surpassing client expectations. We invite you to consider Zhongke as your trusted partner for all your roll-forming machine needs.

OUR CUSTOMERS OF Roof Sheet Roll Forming Machine

Our products are sold to many countries and regions all over theworld, and we have established long-term cooperative relations with clients!

PACKAGING & LOGISTICS OF Door Frame Roll Forming Machine

FAQ

Q1: How to play order?

A1:Inquiry---Confirm the profile drawings and price ---Confirm Thepl---Arrange the deposit or L/C---Then ok

Q2: How to visit our company?

A2: Fly to Beijing airport: By high speed train from Beijing Nan to Cangzhou Xi(1 hour),then we will pick you up.

Fly to Shanghai Hongqiao airport:By high speed train from Shanghai Hongqiao to Cangzhou Xi(4 hour),then we will pick you up.

Q3: Are you manufacturer or trading company?

A3: We are manufacturer and trading company .

Q4: Do you provide installing and training overseas?

A4: Overseas machine install and worker training services are optional.

Q5: How is your after sales support?

A5: We provide technical support on line as well as overseas services by skillful technicians.

Q6: How does your factory do regarding quality control?

A6: There is no tolerance regarding quality control. Quality control complies with ISO9001. Every machine has to past testing running before it's packed for shipment.

Q7: How can I trust you that machines pasted testing running before shipping?

A7: (1) We record the testing video for your reference. Or,

(2) We welcome your visit us and test machine by yourself in our factory

Q8: Do you sell only standard machines?

A8: No. Most machines are customized.

Q9: Will you deliver the right goods as ordered? How can I trust you?

A9: Yes, we will. We are Gold supplier of Made-in-China with SGS assessment (Audit report can be provided).