Color steel stone coated metal roofing tile making machine made in China

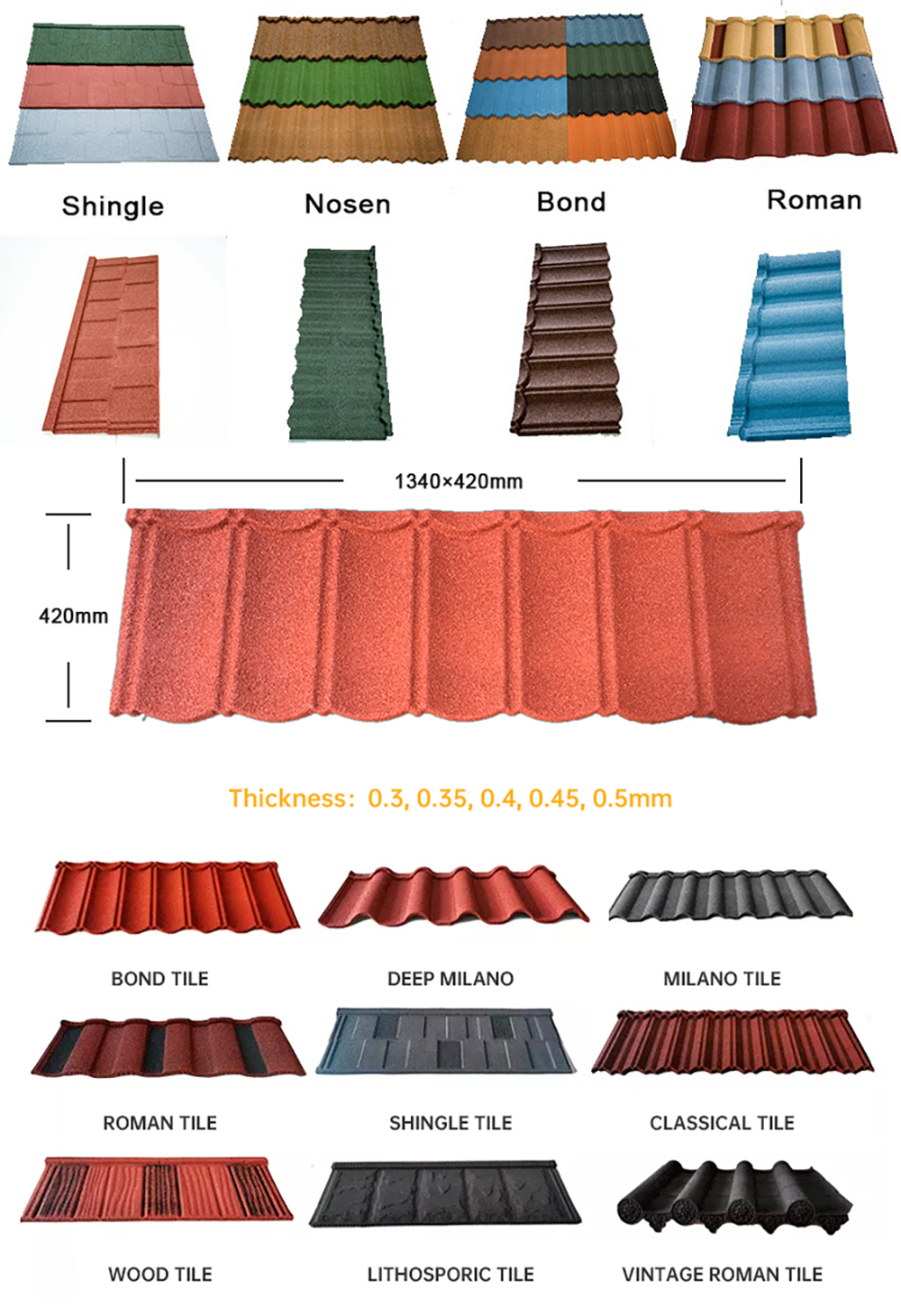

Colorful stone-coated metal roof tile is a modern environmentally friendly roofing material with the basic of 0.4mm Al-zine coated steel.

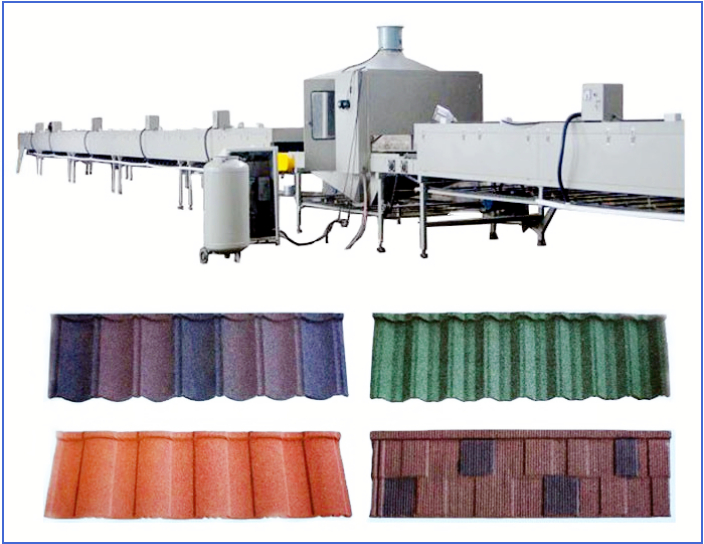

The working speed adopts frequency conversion stepless speed regulation, glue spraying, sanding, and drying are completed at one time.

Covering color vermiculite surface which carried under the high temperature technology.It is high-performance, stable, energy-efficient and easy operation.

Product Overview

Confirm the profile------Got the order-pay advance payment------Start design and make machine(send process photo)-------Nearly finishing machine-------Send invitation letter-------try the machine for inspection-------Pay balance payment--------Delivery machine--------Send documents to clear the custom------Engineer help install if the customer need

|

Main specifications of the production line |

|

| Production speed |

4000-7000pcs/day |

| Machine weight |

About 35MT |

| Total installed capacity |

200 kw,AC380V 50 HZ |

| Suitable material | Coil material color steel sheets, galvanized plates,galvalume plates |

| Steel plate thickness |

0.32-0.5mm |

| Steel plate width |

1000mm-1450mm as per the profile drawing |

| Product condition | Plant area 2000 square mcters(25meters*80meters),Mainframe product environment temperature above 20°C |

| Production line characteristics | Horizontal, continuous product, stepless frequency conversion variable speeds,PLC control, having reliable performances, easy operation. |

The sand spray steel roof sheet linecontains THREE main parts:

Part 1: The roofing tile profile forming

Part 2: Stone coated machines production line

Part 3: Accessories making machines

|

Components of the whole production line |

||

|

Roofing tile profile forming |

Manual decoiler | 1 set |

| Slitting and cutting machine | 1 set | |

| Lace Shearing Machine | 1 set | |

| Hydraulic pressing machine | 1 set | |

|

Stone-coated production line |

Auto bottom glue spraying section | 1 set |

| Auto stone coated section | 1 set | |

| The first time drying section | 1 set | |

| Auto face glue spraying section | 1 set | |

| The second time drying section | 1 set | |

| Accessories making machine

(Ridge tile production line) |

Punching machine | 1 set |

| Rolling machine | 1 set | |

MAIN PARTS DETAILS

Hydraulic Press System

The 315-ton color stone metal tile stamping hydraulic press is a special equipment for stamping and stretching of the color stone

metal tile substrate. The fuselage design adopts a three-beam four-column structure. The equipment is composed of a fuselage, an

oil cylinder, a stroke limit device, and a mold. The structure is simple, economical and practical.

Glue Spray System

Automatic primer spraying equipment (closed automatic glue spraying system) Structure: channel steel, welded

Transmission device:2.2 kilowatt variable Conveying device: reciprocating chain Conveyor adjustment range, 0.1-0.6MPa Automatic glue gun: 4 sets Glue gun: 5 sets Glue gun holder: 1 set

Sand Blasting System

Automatic sandblasting room: 1 set Dimensions: 3000×1850×700 unit mm Structure: channel steel, angle steel, welded

Transmission device: with glue spraying equipment, chain compound transmission Automatic sand bucket: 1 set 550×600×500

Automatic lifting machine: 1 set

Lifting height 1.9 meters, power 300 kg/hour Sandblasting gun: 4 sets.

Drying System

Structure: Welded by carbon steel

Frame insulation wall: 60 meters, 1 mm thick cold plate bending forming insulation cotton

Filling Infrared heating tube: 100 pieces Automatic temperature controller: 2 sets of temperature adjustment range 0-160°

Cooling device: 1 set

PRODUCT APPLICATION

Stone coated metal roof tile making machine production line use for make different types stone coated roofing sheet,the roof tile mould type and size can be customized,we also supply raw material for stone coated.

PACKING AND SHIPPING

1). Container packing of the line suitable for overseas shipping

2). The subjects can be loaded in one 40’ container.

3). Package style: Covered by plastic film, spare parts and some small parts packed in carton box.

4).we have a good cooperation with the shipment company ,we give the client the best transport plan and the best freight cost.