Introduction of Zhongke Roll Forming Machine Factory

Zhongke press watt machine factory spirit of "people-oriented, innovation and truth" principle, to "quality first, customer first, quality service, abide by the contract" for the purpose, with strong economic strength, advanced management mode, strong technical force, perfect testing means and reliable quality assurance system, dedicated to provide our customers with quality service. We warmly welcome new and old customers to visit the factory to guide the work. We sincerely look forward to working with you to create a better tomorrow!

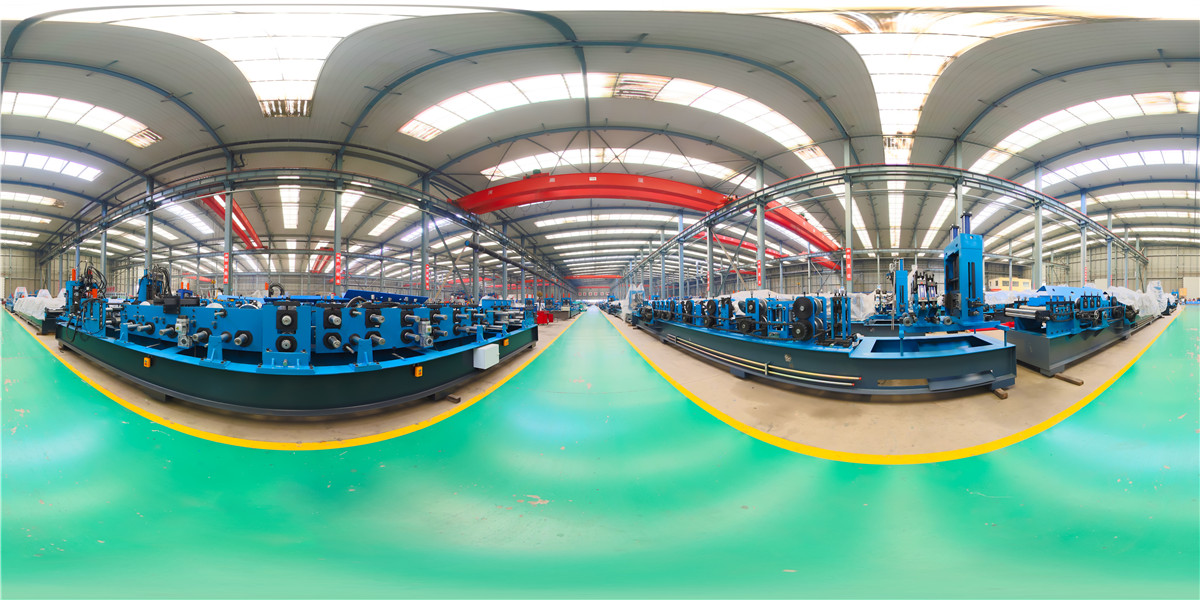

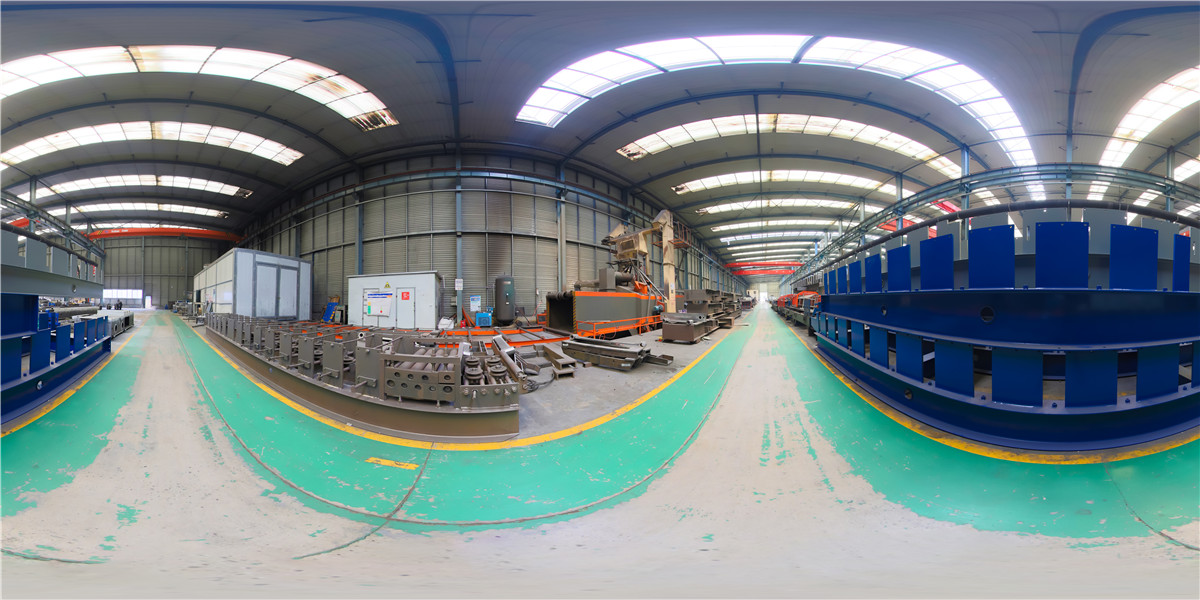

Botou zhongke Roll Forming Machine Factory was founded in 1996, is a professional production of heavy machinery and equipment of large enterprises. After years of development, we have now developed into a collection of scientific research, development, production, sales, service in one of the large enterprises. Our products cover all fields of heavy machinery and equipment, and are in a leading position in the heavy machinery industry. Our products have been well received by users.

Now the large hydraulic tile pressing equipment produced by our company has reached the international advanced level, especially the patented product developed by our company (ZL200910302633.6), which won the National Science and Technology Innovation Award and the National Key New Product Award. This not only plays a promoting role for our country's heavy machinery industry, but also has won more honors for our enterprise.

Introduction of Equipment

Press tile machine is the use of hydraulic transmission, with steel plate, section steel, Angle steel as raw materials, through the automatic feeding, forming, cutting, stripping and other processes made of various specifications of color steel tile. Suitable for all kinds of building roofing color steel tile forming. Because the tile press is connected into one by the hydraulic transmission system of two or more presses, it is called hydraulic tile press.

The working process of the tile press is that the steel coil is sent to the forming mechanism by the feeding mechanism, which will stretch the steel plate, section steel or Angle steel and other materials to form, and then the tile blank is demoulded by the demoulding mechanism. Because the mechanism adopts hydraulic transmission, it is also called hydraulic tile press. During the molding process, the pressure oil in the hydraulic cylinder is transported to the cylinder by the oil pump through the oil cooler, and the oil in the cylinder is cooled and returned to the oil pump through the tubing. In addition, the mechanism can also heat treat the billet after heating and cooling. After heat treatment, the billet is sent to the cutting line by conveyor belt. After cutting, the cutting line is sent to the top material area.

Equipment Characteristics

1, the machine is hydraulic automatic, through the expansion of the hydraulic cylinder and the movement of the upper and lower pressure head to achieve the compression of tile;

2, the equipment operation is simple, automatic production, save the trouble of manual operation and handling tile;

3, this machine production of product size complete, suitable for all kinds of specifications tile type production;

4, the machine adopts a pressing molding process, can ensure the accuracy and consistency of tile size, high production efficiency, low labor cost;

5, the equipment structure is compact, covers a small area;

6. High degree of equipment automation, saving labor cost;

7, the equipment covers a small area, quick and convenient installation;

8, can be equipped with hydraulic system according to customer requirements. We have experienced technicians and engineers to design various specifications and models of the tile press;

9, the machine adopts hydraulic drive and PLC control system, high degree of automation;

10, the hydraulic cylinder as the upper and lower pressure head power, so high production efficiency;

11, the equipment adopts double head feeding and pressure tile, so the product quality is good. The factory uses a variety of safety protection devices (such as emergency braking) to protect staff and equipment;

Advantages of Equipment

1, advanced production equipment: the use of advanced hydraulic transmission, high precision, fast production speed;

2, perfect detection means: the whole factory implements microcomputer automatic management, and in line with international standards;

3, advanced technology: double hydraulic pressing molding, with high density, high strength, light weight and other advantages;

4, perfect after-sales service: 24 hours open telephone line, 24 hours to arrive at the scene to provide technical support;

5, sound quality management system: from design to production, the implementation of total quality management, in strict accordance with the ISO9001:2000 standards.

6, perfect sales network: The factory through the establishment of close relations with dealers all over the country, timely understanding of the market dynamics.

7, high quality product quality: I plant adhere to the "customer satisfaction" for the purpose, in strict accordance with the ISO9001 standard implementation. A strict quality management system has been established to ensure the quality of products.