2024 ZKRFM Metal Advanced Floor Deck Forming Machine

Product descriptions from the supplier Overview

Product details of zhongke corrugated forming machine:

The Zhongke an advanced metalworking equipment designed for the efficient production of steel floor decks, essential components in construction for composite floor slabs. This machine automates the process of shaping and punching steel sheets into profiled decks, ensuring precision and speed. It features adjustable roller stations to form various deck profiles, along with hydraulic cutting systems for clean and accurate length cuts. With easy-to-use controls and high-production capacity, it significantly enhances productivity while maintaining superior product quality, making it a cornerstone tool in modern structural steel fabrication industries.

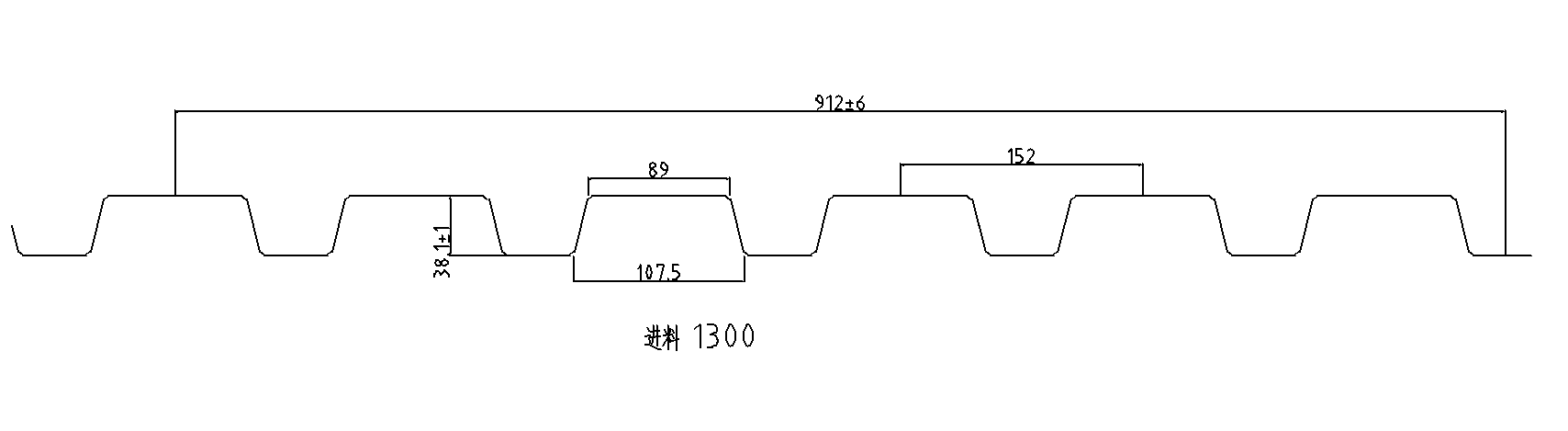

Product standard drawings and parameters:

| Type | Tile Forming Machine |

| Tile Type | Colored Glaze Steel |

| Production Capacity | 10-15m/min |

| Rolling thinckness | 0.3-0.8mm |

Other attributes

| Applicable Industries | Hotels, Building Material Shops, Manufacturing Plant, Home Use, Construction works |

| Showroom Location | None |

| Place of Origin | HEB |

| Weight | 4800 kg |

| Warranty | 1 Year |

| Key Selling Points | High Productivity |

| Feeding width | 1080mm |

| Machinery Test Report | Provided |

| Video outgoing-inspection | Provided |

| Marketing Type | New Product 2024 |

| Warranty of core components | 1 Year |

| Core Components | Pressure vessel, Motor, Pump, PLC |

| Condition | New |

| Use | ROOF |

| Brand Name | HN |

| Voltage | 380V 50Hz 3phases or as your requirement |

| Dimension(L*W*H) | 8700*1500*1500mm |

| Product name | Floor Deck Roll Forming Machine |

| Usage | Wall Panel |

| Control system | PLC(detla) System |

| Shaft material | 45# Steel |

| Cutting type | Automatic Hydraulic Cutting |

| Color | Custimized |

| Profiles | corrugated |

| Suitable material | GI GL PPGI PPGL |

| Thickness | 0.3mm-0.8mm |

| Function | Roof Usage |

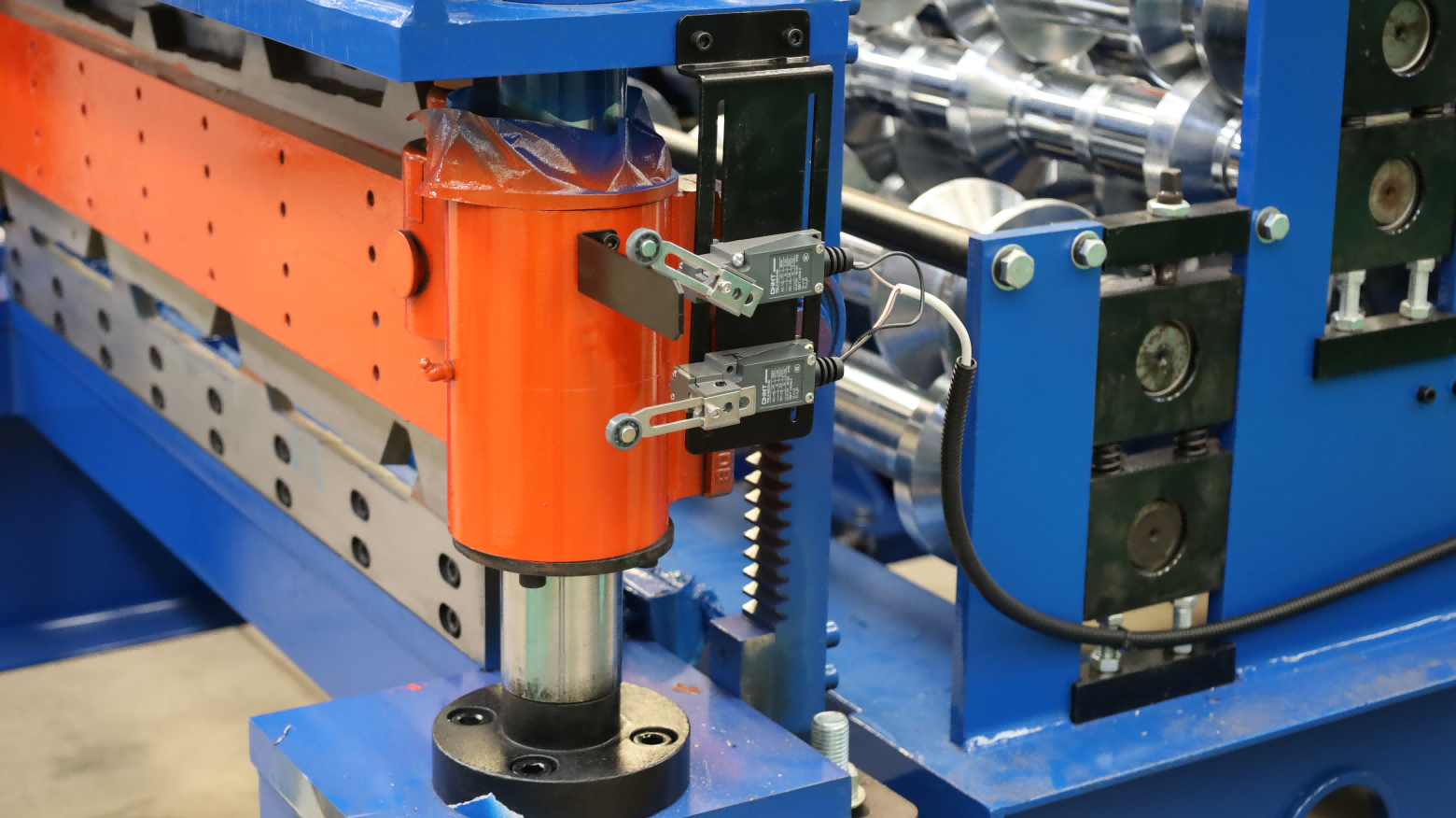

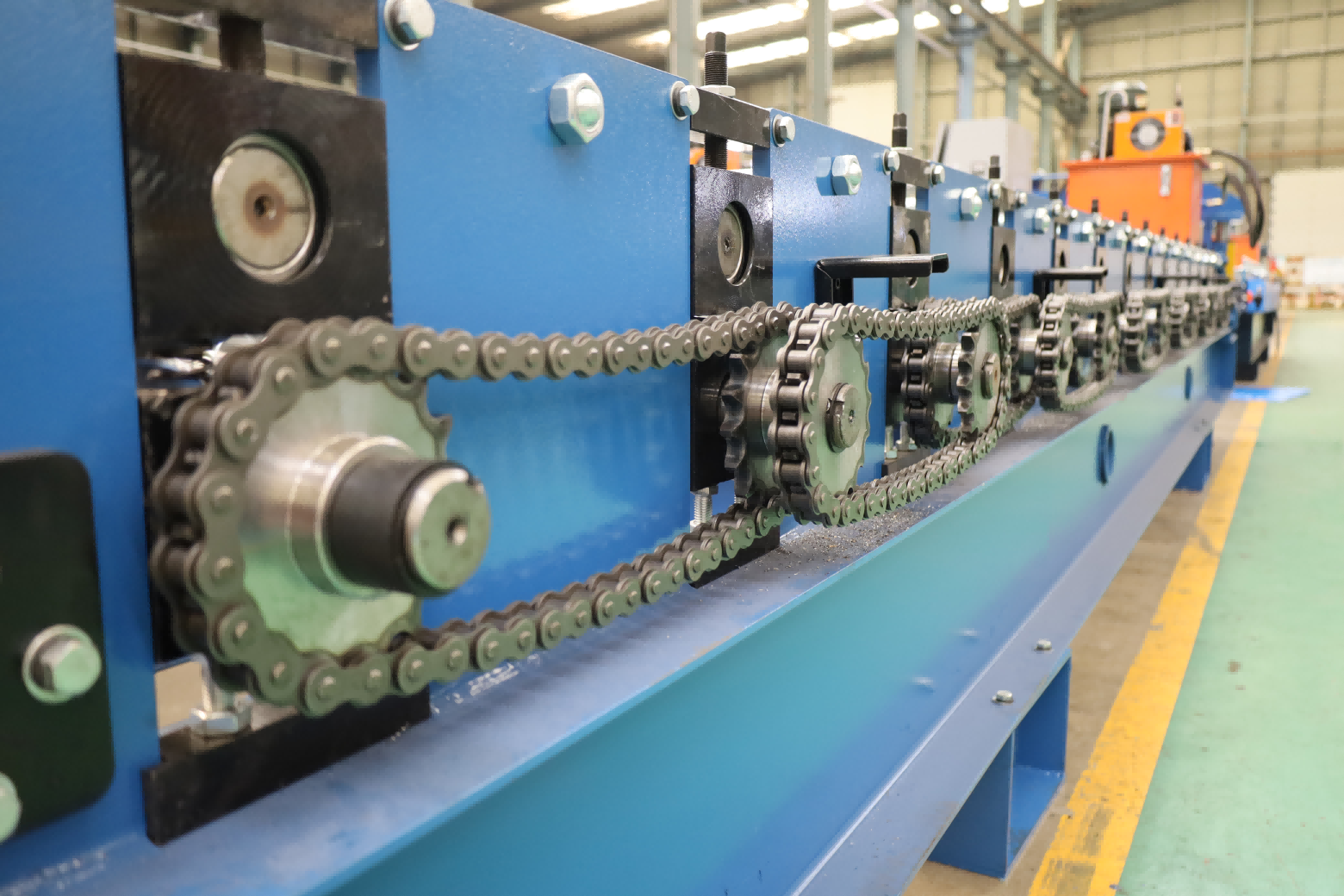

This realistic image vividly shows the application of the floor slab forming machine in the modern construction industry, which not only captures the moment of efficient operation of the machine, but also shows how it magically transforms the cold-rolled steel coil into a durable floor slab, laying a solid ground foundation for high-rise buildings. The light falls on the precision roller and the automated production line, highlighting the perfect integration of science and technology and manufacturing, and the precise forming of every inch of steel plate is a lofty tribute to the process aesthetics and architectural strength.

Machine detail of corrugated forming machine:

Company introduction:

Zhongke Roll Forming Machine Factory has been deeply involved in the field of rolling technology for 20 years. It has gathered hundreds of elite craftsmen and has a modern workshop of 20,000 square meters, showing a magnificent manufacturing picture. We are renowned in the industry for our unique high-end machinery, personalized customized services and flexible solutions. We are especially good at creating exclusive products based on our customers' vision. From the light and tough steel frame to the glazed tiles with ancient and modern charm, all-round panel forming from roofs to walls, and even C/Z-shaped steel production lines, Zhongke has cleverly built a leading position in the construction field with its extensive product matrix. Diverse dreams. We are passionate and determined to exceed expectations, and strive to achieve extraordinary results in every cooperation. We sincerely invite you to join hands with Zhongke to embark on a journey of exploration of innovation and excellence, opening a new era of cooperation.

OUR CUSTOMERS OF Zhongke

Our products are sold to many countries and regions all over theworld, and we have established long-term cooperative relations with clients!

PACKAGING & LOGISTICS OF Door Frame Roll Forming Machine

FAQ

Q1: How to play order?

A1:Inquiry---Confirm the profile drawings and price ---Confirm Thepl---Arrange the deposit or L/C---Then ok

Q2: How to visit our company?

A2: Fly to Beijing airport: By high speed train from Beijing Nan to Cangzhou Xi(1 hour),then we will pick you up.

Fly to Shanghai Hongqiao airport:By high speed train from Shanghai Hongqiao to Cangzhou Xi(4 hour),then we will pick you up.

Q3: Are you manufacturer or trading company?

A3: We are manufacturer and trading company .

Q4: Do you provide installing and training overseas?

A4: Overseas machine install and worker training services are optional.

Q5: How is your after sales support?

A5: We provide technical support on line as well as overseas services by skillful technicians.

Q6: How does your factory do regarding quality control?

A6: There is no tolerance regarding quality control. Quality control complies with ISO9001. Every machine has to past testing running before it's packed for shipment.

Q7: How can I trust you that machines pasted testing running before shipping?

A7: (1) We record the testing video for your reference. Or,

(2) We welcome your visit us and test machine by yourself in our factory

Q8: Do you sell only standard machines?

A8: No. Most machines are customized.