2024 Metal Automatic Advanced Photovoltaic bracket C steel Automatic Cold Roll Forming Machine

Main selling points

We have the following features:

1.Integrated Manufacturing and Trading. Our company operates as a combined manufacturer and trader, offering direct access to factory pricing and a comprehensive suite of services.We have a strong presence in the global market, ensuring that we stay up-to-date with the latest trends and customer needs.

2.Full Automation. Equipped with advanced CNC control systems, our press brake machine automates the entire bending process, from sheet loading to finished product.Features automatic tool change and angle adjustment, reducing setup times and increasing throughput.

3.Stability and Durability: Constructed with high-grade materials and precision-engineered components for maximum stability and minimal maintenance.Robust frame design and tight tolerances ensure consistent performance over long periods of use.

4.High Efficiency: Rapid bending speeds and quick tool changes significantly increase production rates.Energy-efficient motors and optimized hydraulic systems reduce operating costs.

5.User-Friendly Interface: Intuitive control panel with touch screen interface for easy programming and monitoring.Real-time data tracking and analysis for improved quality control and process optimization.

6.Customizable Options:T ailored solutions to meet specific customer requirements, including custom tooling and software configurations.Compatibility with a variety of materials and thicknesses for flexibility in application.

7.Safety Features: Comprehensive safety protocols, including light curtains and emergency stop buttons, ensure operator safety.Compliance with international safety standards for peace of mind.

Product descriptions from the supplier Overview

Product details of zhongke Photovoltaic bracket forming machine

The Zhongke of Photovoltaic bracket C Automatic Cold Roll Forming Machine is a high-efficiency, fully automated solution designed for the production of high-quality ridge tiles. With integrated manufacturing and trading capabilities, this machine offers precision roll forming, rapid tool changes, and a user-friendly digital control panel. Constructed with durable materials and featuring a compact design, it ensures stable and efficient operation. The machine is capable of processing a variety of materials, providing consistent and precise results. Ideal for construction projects, it streamlines the production process and maximizes productivity.

Product standard drawings and parameters

| Type | Tile Forming Machine |

| Tile Type | Colored Glaze Steel |

| Production Capacity | 20-25m/min |

| Rolling thinckness | 0.3-0.8mm |

Other attributes

| Applicable Industries | Hotels, Building Material Shops, Manufacturing Plant, Home Use, Construction works |

| Showroom Location | None |

| Place of Origin | HEB |

| Weight | 4800 kg |

| Warranty | 1 Year |

| Key Selling Points | High Productivity |

| Feeding width | 1200mm |

| Machinery Test Report | Provided |

| Video outgoing-inspection | Provided |

| Marketing Type | New Product 2024 |

| Warranty of core components | 1 Year |

| Core Components | Pressure vessel, Motor, Pump, PLC |

| Condition | New |

| Use | ROOF |

| Brand Name | HN |

| Voltage | 380V 50Hz 3phases or as your requirement |

| Dimension(L*W*H) | 8700*1500*1500mm |

| Product name | Photovoltaic bracket C Forming Machine |

| Usage | Wall Panel |

| Control system | PLC(detla) System |

| Shaft material | 45# Steel |

| Cutting type | Automatic Hydraulic Cutting |

| Color | Custimized |

| Profiles | corrugated |

| Suitable material | GI GL PPGI PPGL |

| Thickness | 0.3mm-0.8mm |

| Function | Roof Usage |

In a spacious and well-lit industrial facility, the C-Type Steel Automatic Cold Roll Forming Machine stands at the heart of the production line. Its sleek and robust frame houses high-precision rollers that transform flat steel strips into precise C-shaped profiles. The machine's fully automated process begins as a coil of steel is unwound and fed into the machine. The rollers, made from imported DC53 material, guide the strip through a series of calibrated bends, shaping it into the distinctive C-profile. The hydraulic cutting system, powered by a 5.5KW motor, precisely cuts the formed sections to the desired length. Finished C-Type steel pieces are collected in a tray, ready for further processing or installation. Surrounding the machine are stacks of completed profiles, testament to the machine's efficiency and the quality of its output. The scene exemplifies the seamless integration of advanced technology and robust manufacturing practices, ensuring the production of high-quality C-Type steel components for various construction and fabrication projects.

Machine detail of Photovoltaic bracket machine

| Decoiler

The Zhongke Decoiler efficiently handles steel coils, bearing & rotating them. It features a micro brake to prevent sudden stops, ensuring safety during inertia forward operation. Accepts coils with inner diameters 430-580mm and outer up to 1300mm. |

|

| 300 H Frame

The 300 H Frame is an integral part of our roll forming machine, providing robust support and stability. It ensures precise alignment and consistent product quality during the production process. |

|

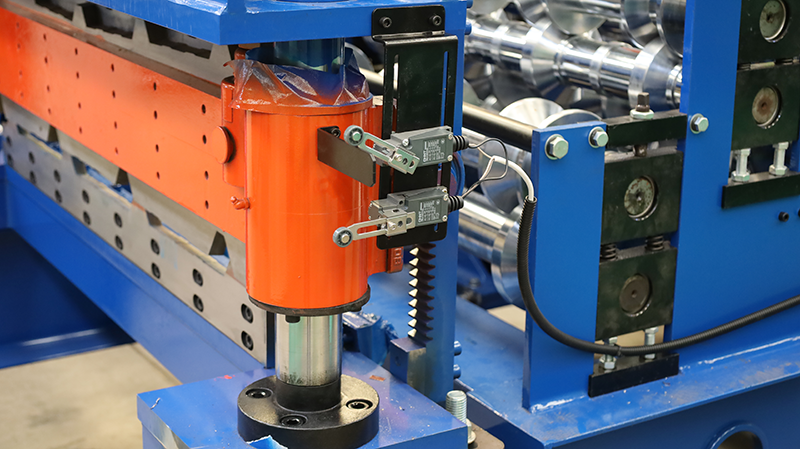

| Travel switch

The Travel Switch is an essential component of our roll forming machine, ensuring precise and automated positioning of materials. It enhances efficiency and accuracy in the production process, making it a valuable tool for our customers. |

|

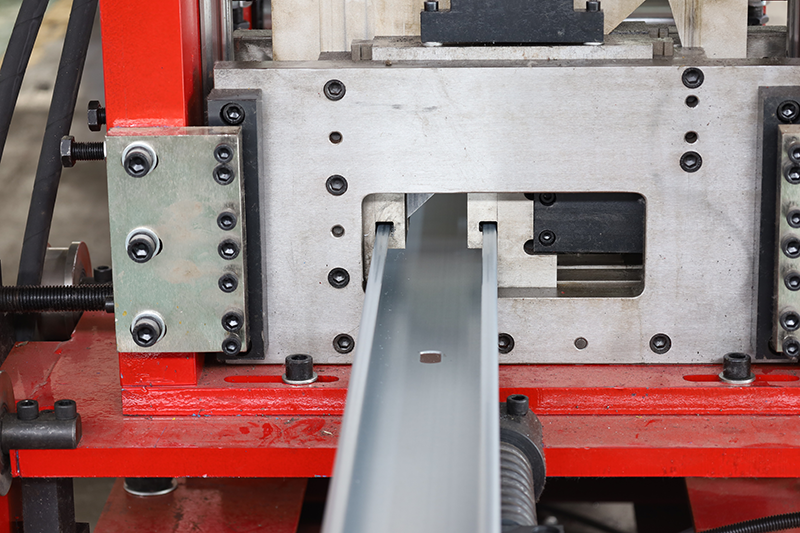

| Punching Device

The punching device on the roll forming machine is a specialized component designed to efficiently punch holes or shapes into the material as it passes through the forming process. This innovative feature significantly enhances the versatility and productivity of the roll forming machine by allowing for the precise and rapid creation of various patterns, perforations, and cutouts in the metal sheets. |

|

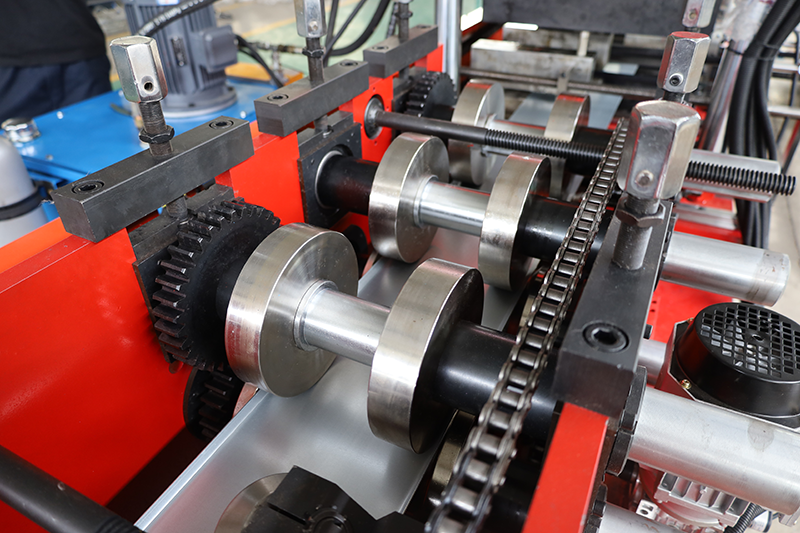

| Gearbox Transfer

The gearbox on our roll forming machine functions as a critical component, efficiently transmitting power and reducing speed to drive the rollers, ensuring precise and smooth metal shaping. |

|

| The high hardness roller used in our roll forming machines is made from imported DC53 material, ensuring exceptional durability and wear resistance. This material is known for its excellent toughness and heat treatment properties, making it ideal for demanding industrial applications. | |

| PLC control box

Our PLC control box seamlessly integrates with your roll forming machine, offering precise control and automation. Streamline operations, optimize production, and ensure consistent, high-quality output with ease. |

|

| The cutting mechanism in our roll forming machines utilizes a hydraulic cutting system, which provides precise and efficient cutting of the formed metal profiles. This system is designed to ensure clean, burr-free cuts, enhancing the overall quality of the finished products. |

Company introduction

For two decades, Zhongke Rolling Machinery Factory has been deeply rooted in the fertile ground of rolling technology, bringing together a team of over a hundred master craftsmen. Our modern facility spans over 20,000 square meters, equipped with state-of-the-art machinery, painting a grand picture of industrial manufacturing excellence.

We are renowned for our high-end machinery, personalized service approach, and flexible solutions tailored to meet diverse client needs. Specializing in transforming client visions into unique masterpieces, whether it's lightweight yet robust steel structures, or the fusion of classical and contemporary beauty in glazed roof tiles, we provide comprehensive solutions for roofing and wall cladding applications, as well as efficient C/Z-type steel production lines. With a rich and diverse product portfolio, Zhongke skillfully crafts the colorful dreams of the architectural world.

Driven by passion, we strive to exceed expectations with every project, ensuring that every collaboration is marked by outstanding achievement. Today, we extend a warm invitation to join forces with Zhongke on a journey of innovation and excellence, opening a new chapter of partnership and creating a brilliant future together.

OUR CUSTOMERS OF Zhongke Photovoltaic bracket forming machine

Our products are sold to many countries and regions all over theworld, and we have established long-term cooperative relations with clients!

PACKAGING & LOGISTICS OF Zhongke Shutter Door Roll Forming Machine

FAQ

Q1: How to play order?

A1:Inquiry---Confirm the profile drawings and price ---Confirm Thepl---Arrange the deposit or L/C---Then ok

Q2: How to visit our company?

A2: Fly to Beijing airport: By high speed train from Beijing Nan to Cangzhou Xi(1 hour),then we will pick you up.

Fly to Shanghai Hongqiao airport:By high speed train from Shanghai Hongqiao to Cangzhou Xi(4 hour),then we will pick you up.

Q3: Are you manufacturer or trading company?

A3: We are manufacturer and trading company.Had very greatful experience.

Q4: Do you provide installing and training overseas?

A4: Overseas machine install and worker training services are optional.

Q5: How is your after sales support?

A5: We provide technical support on line as well as overseas services by skillful technicians.

Q6: How does your factory do regarding quality control?

A6: There is no tolerance regarding quality control. Quality control complies with ISO9001. Every machine has to past testing running before it's packed for shipment.

Q7: How can I trust you that machines pasted testing running before shipping?

A7: (1) We record the testing video for your reference. Or,

(2) We welcome your visit us and test machine by yourself in our factory

Q8: Do you sell only standard machines?

A8: No. Most machines are customized.