2024 Metal Automatic Advanced Highway Guardrail Automatic Cold Roll Forming Machine

We have the following features:

1. High efficiency and energy saving: using advanced servo motor control system to ensure high-speed operation while reducing energy consumption and saving operating costs.

2. Versatility: Supports tile molding of various specifications and styles. Users can quickly change molds according to actual needs to adapt to different architectural styles.

3. Precise control: Equipped with a high-precision digital control system to ensure that the size and shape of each tile are consistent and improve the yield.

4. Durable material: The main components are made of high-strength alloy steel. After special treatment, they are wear-resistant and corrosion-resistant, extending the service life.

5. Safe and reliable: Integrated multiple safety protection measures, including emergency stop button, overload protection, etc., to ensure the safety of operators.

6. Easy to maintain: The modular design facilitates daily maintenance and repair, reduces downtime and improves work efficiency.

7. Customized services: Provide personalized solutions and tailor production line configurations according to customer needs to meet specific production requirements.

Product descriptions from the supplier

Overview

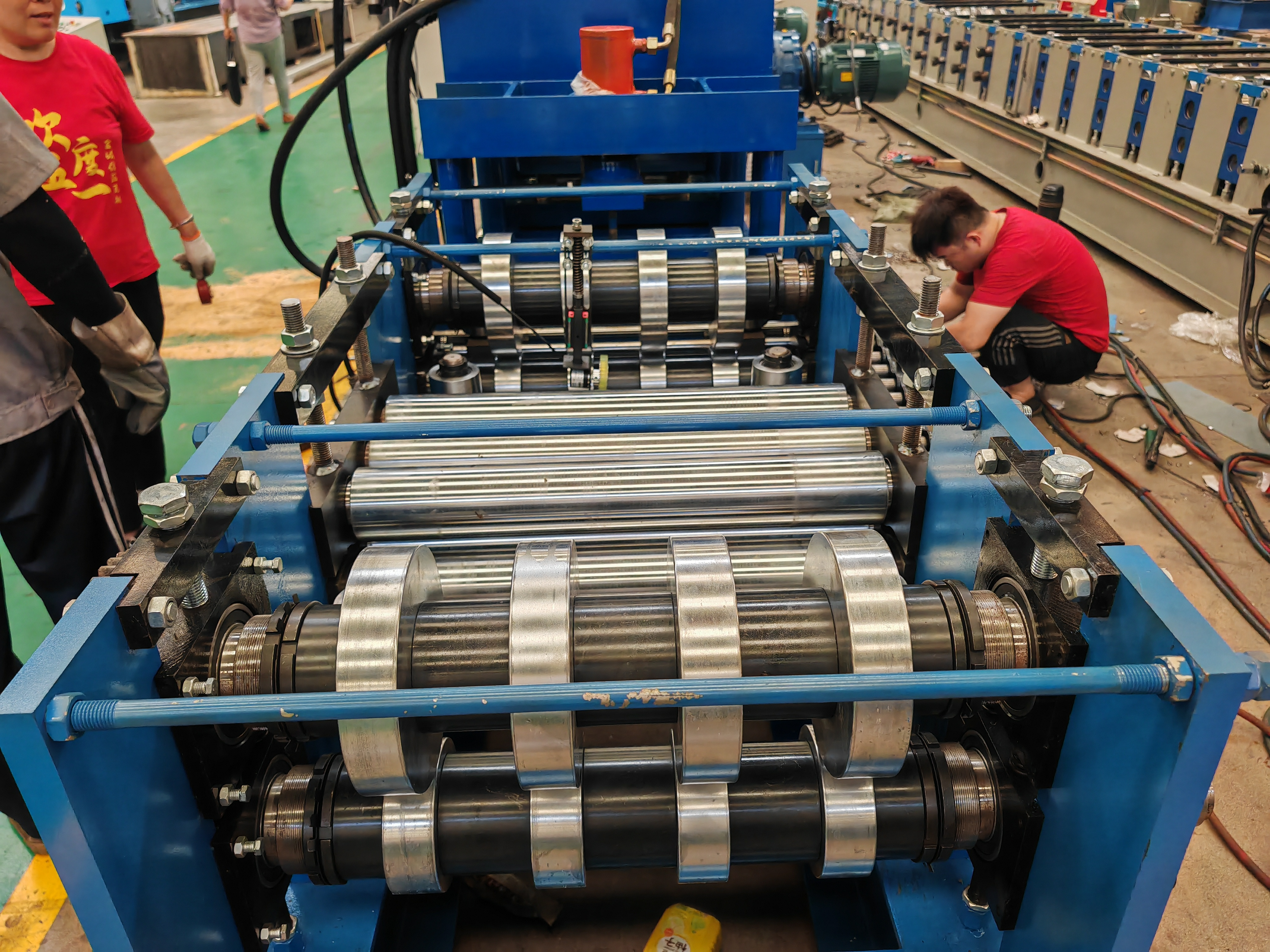

Product details of zhongke corrugated forming machine:

The Zhongke of Highway Guardrail Automatic Cold Roll Forming Machine is a state-of-the-art equipment designed for the efficient manufacture of highway guardrails. It employs a continuous cold rolling process, automatically shaping steel strips into the precise profiles required for road safety barriers. With features like PLC control, automatic material feeding, and in-line punching, this machine ensures high production speed, precision, and minimal labor intervention. Its robust construction and advanced technology guarantee the production of consistent, high-quality guardrails, contributing significantly to roadside safety standards worldwide.

Product standard drawings and parameters:

| Type | Tile Forming Machine |

|---|---|

| 张三 | Colored Glaze Steel |

| Production Capacity | 20-25m/min |

| Rolling thinckness | 0.3-0.8mm |

Other attributes

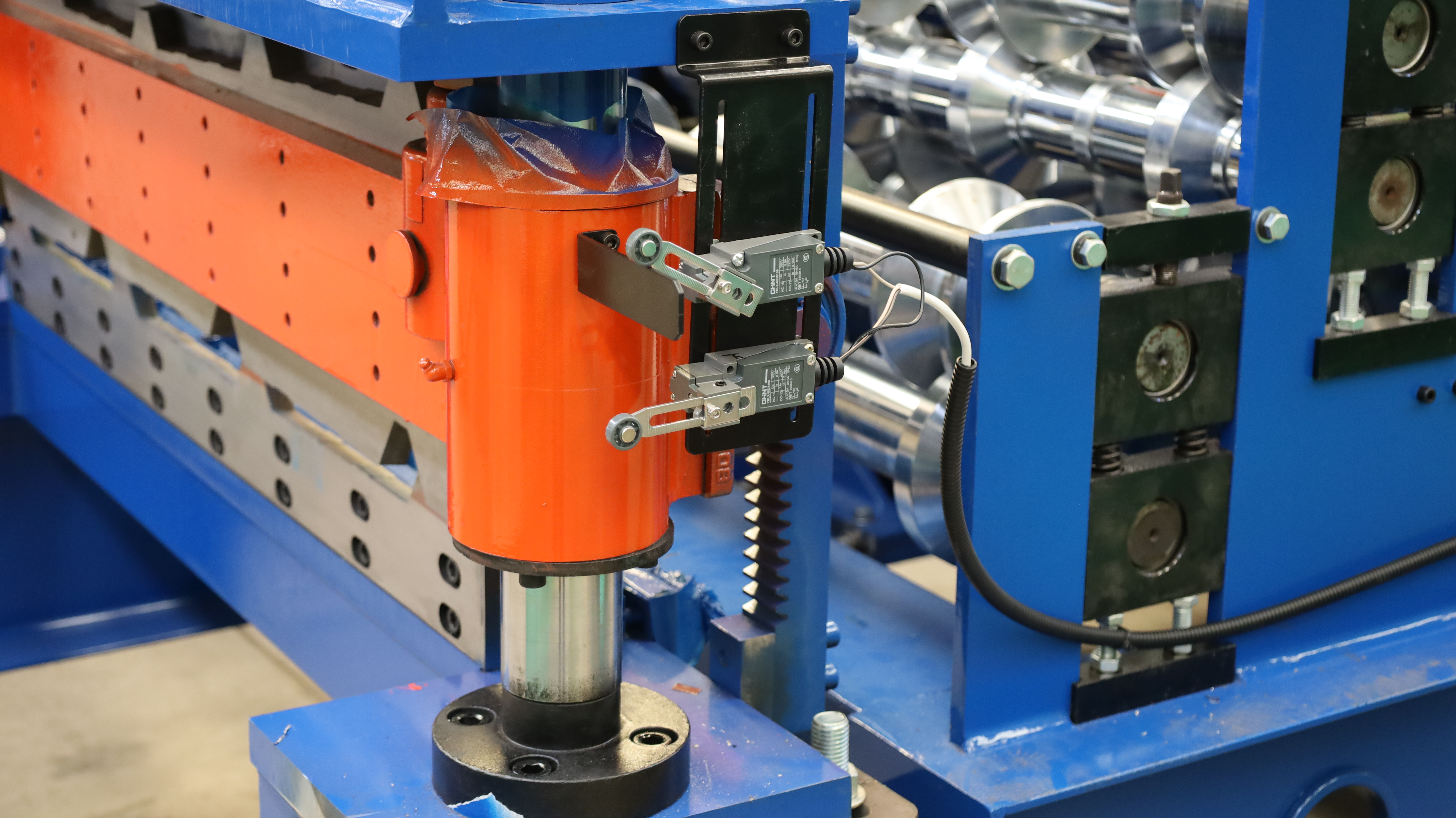

This realistic image vividly shows the application of the floor slab forming machine in the modern construction industry, which not only captures the moment of efficient operation of the machine, but also shows how it magically transforms the cold-rolled steel coil into a durable floor slab, laying a solid ground foundation for high-rise buildings. The light falls on the precision roller and the automated production line, highlighting the perfect integration of science and technology and manufacturing, and the precise forming of every inch of steel plate is a lofty tribute to the process aesthetics and architectural strength.

Machine detail of corrugated forming machine:

Zhongke Rolling Machinery Factory has been deeply rooted in the fertile ground of rolling technology for 20 years. It has gathered hundreds of master craftsmen with outstanding skills. It has a modern factory covering an area of 20,000 square meters and is equipped with advanced equipment. It has unfolded a spectacular Industrial manufacturing landscape. We have earned a high reputation in the industry for our exquisite high-end machinery and equipment, tailor-made service concepts, and flexible solutions to various needs. We are particularly good at transforming customers' vision into unique products, whether it is a light and strong steel structure frame, or a glazed tile that combines classical and modern beauty, a full range of panel forming solutions from roof covering to wall wrapping, and even efficient With its C/Z-shaped steel production line, Zhongke has cleverly built colorful dreams in the construction industry with its rich and diversified product lines. We are passionate and committed to exceeding every expectation, ensuring that every partnership delivers extraordinary results. At this moment, we sincerely invite you to join hands with Zhongke to embark on a journey of exploration integrating innovation and excellence, open a new chapter of cooperation, and create a brilliant future together.

OUR CUSTOMERS OF Zhongke

Our products are sold to many countries and regions all over theworld, and we have established long-term cooperative relations with clients!

PACKAGING & LOGISTICS OF Zhongke Top Hat Section Channel Machine

FAQ

Q1: How to play order?

A1:Inquiry---Confirm the profile drawings and price ---Confirm Thepl---Arrange the deposit or L/C---Then ok

Q2: How to visit our company?

A2: Fly to Beijing airport: By high speed train from Beijing Nan to Cangzhou Xi(1 hour),then we will pick you up.

Fly to Shanghai Hongqiao airport:By high speed train from Shanghai Hongqiao to Cangzhou Xi(4 hour),then we will pick you up.

Q3: Are you manufacturer or trading company?

A3: We are manufacturer and trading company.Had very greatful experience.

Q4: Do you provide installing and training overseas?

A4: Overseas machine install and worker training services are optional.

Q5: How is your after sales support?

A5: We provide technical support on line as well as overseas services by skillful technicians.

Q6: How does your factory do regarding quality control?

A6: There is no tolerance regarding quality control. Quality control complies with ISO9001. Every machine has to past testing running before it's packed for shipment.

Q7: How can I trust you that machines pasted testing running before shipping?

A7: (1) We record the testing video for your reference. Or,

(2) We welcome your visit us and test machine by yourself in our factory

Q8: Do you sell only standard machines?

A8: No. Most machines are customized.