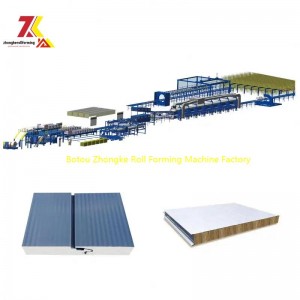

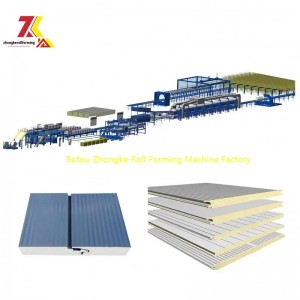

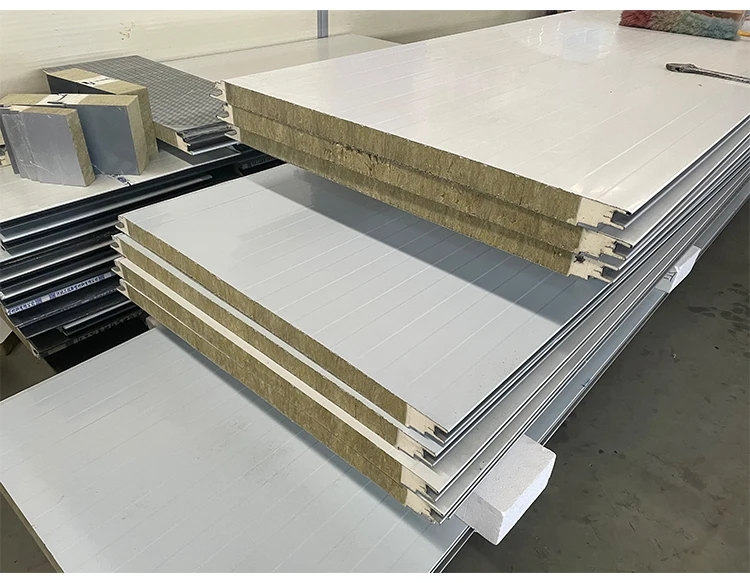

2024 High Speed Automatic polyurethane machines Phenolic Insulated Polyurethane Sandwich Foam Forming Panel Machine

What should be used in the Phenolic Insulated Panel Machine?

The rock wool board production line is a complete system for the production of rock wool boards. It uses an electronic metering automatic feeding system to add raw materials to a closed furnace for melting. After forming fibers through a four-roll centrifuge, add an appropriate amount of binder. Cotton collecting machine, pendulum cloth cotton machine, and pleating pre-pressing machine are sent to the curing furnace to make boards, and then cooled, cut, waste edge recycling, automatic board stacking machine, and the production of packaging rock wool boards.

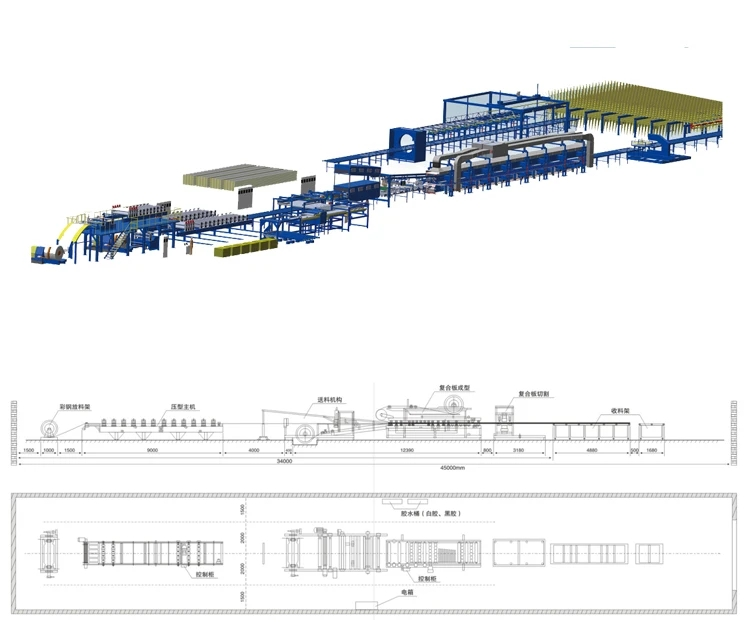

The Phenolic Insulated Panel Machine mainly includes:

1. Raw material feeding system: automatic batching machine, control cabinet, feeding machine.

2. Melting system: furnace frame, cupola, melting furnace material level control system, dust collector, waste gas combustion furnace, waste gas induced air pipeline, exhaust gas induced draft fan, heat exchanger control cabinet, melting furnace cooling system, melting furnace air supply fan , Melting furnace air supply pipeline.

3. Cotton making system: high-speed centrifuge, fan, cotton blowing bellows, centrifuge lubrication system, water pump and cooling system, electric control cabinet, slag remover.

5. Cotton collecting and cotton distributing system: cotton collecting machine and pendulum cotton distributing machine control cabinet, cotton collecting induced draft fan, cotton collecting dust collector.

6. Board making system: cloth cotton conveyor, pressurized folding machine, curing furnace, active power assembly, control cabinet.

7. Explosion-proof system of curing furnace: natural gas detection system, explosion-proof fan, explosion-proof pipeline, control cabinet.

8. Cutting system: cooling conveyor, cooling fan, longitudinal cutting machine, horizontal cutting machine cutting and measuring device, control cabinet, cutting machine power system.

9. Cutting dust removal system: bag filter, dust removal pipeline, dust removal fan.

10. Hot air system of curing furnace: heat-resistant fan, gas hot air stove, gas burner, hot air pipeline.

11. Waste edge recovery system: shredder, edge recovery fan, edge recovery pipeline.

12. Auxiliary equipment: glue making equipment, automatic palletizing machine, packaging machine, slitting machine.

Packaging & Shipping

Phenolic Insulated Panel Machine

Packing Details : 1*40 GP container ; main machine naked and fastened with iron wire in the container.

Delivery Details : 30-35 days after order of Solid bicycle tire tubes

Our Services

1- All inquiries replied after 12 hours

2- Professional will send some full details about the machine in different languages (Chinese, English, French, Spanish, Arabic)

3- Overseas engineer available after-service

4- Some video will send to you related to the product

5- Warranty for one year.

6- Any questions, contact anytime.

7- Any visit, can provide invitation letter.

8- Spare- part in need, can be given

9- Offering reasonable price with a quality machine